So...brakes.

The brakes on Boomer have never been confidence inspiring. The pedal has always been firm but an increase in pedal pressure has never led to a proportionally significant reduction in speed. "Locking up the tires" just doesn't happen.

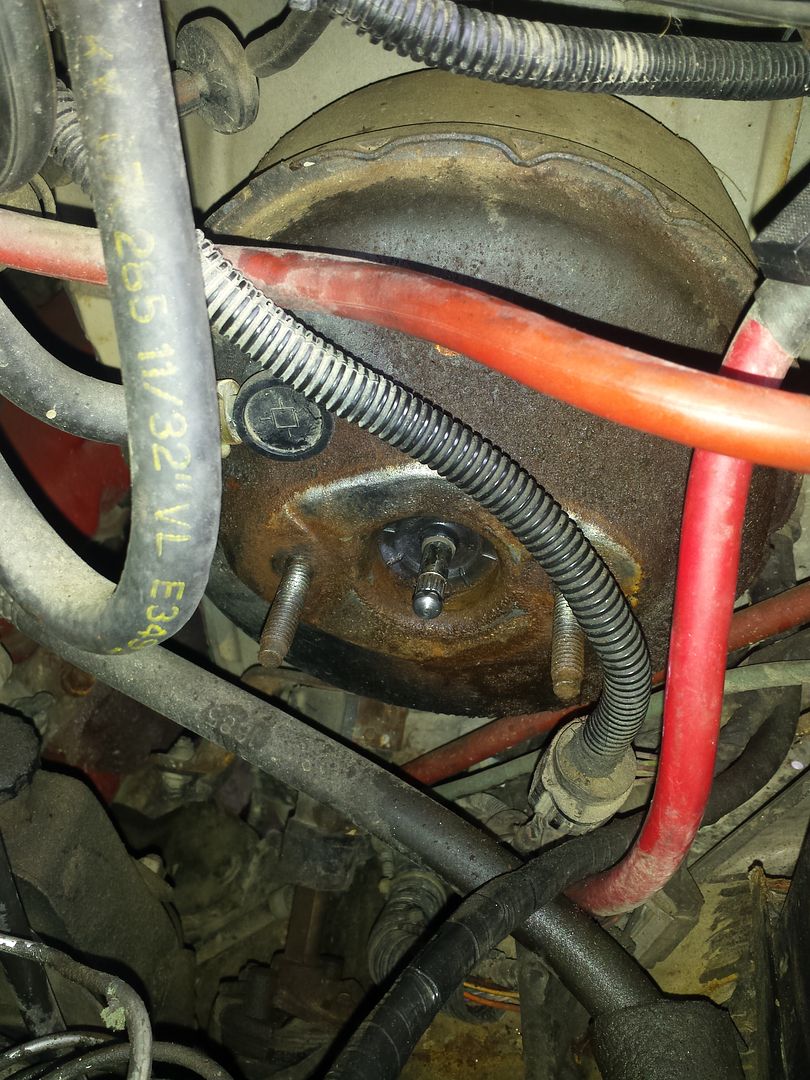

The master cylinder and booster are stock 1985 E350. Vacuum pump off the engine goes to a small vacuum reservoir (made from PVC end caps thank you very much...original rusted away long ago) and powers a standard single diaphragm vacuum booster. The master cylinder is a 1.125" bore with 2 isolated circuits (and isolated fluid reservoirs). There is no proportional valve or brake failure switch in the stock circuit, and a load sensing rear bias valve was installed in the rear connected between the axle and frame.

The front brakes are stock 2 piston 1985 Ford E350 calipers with what seem to be late 70's Ford F250 12.5" rotors. The brake pads have been upgraded to remarkably spendy (and just as remarkably good) Hawk Performance Extreme Duty units.

The rear brakes were stock drums with relatively fresh hardware and pads.

None of this ever really has worked right.

It was finally time to get a handle on braking.

Phase 1 involved swapping to Hawk Performance Extreme Duty front pads. This was a really good upgrade for the fronts. As they warm up they just keep clamping harder. A drastic improvement over the Napa brand semi metallic pads I was previously running. While I swapped pads I also blew out one of the seals on the driver side caliper, so I'm running a new one of those as well.

After phase 1 Boomer was run for around 1000 miles. It was decided that Phase 2 was in order.

Phase 2 has involved a rear disc brake upgrade. After a bit of searching on the Googles, it became clear that upgrading a rear full float Dana 60 to disc brakes isn't much of a chore.

-1980 Chevy K20 (3/4 ton 4x4) Front Rotors

-1980 Chevy K20 Front Calipers and Pads

-Bolt-On Adapter Brackets

-Various adapter hoses

-Proportional Brake Balance Valve

So after the parts all arrived it was time to disassemble.

Everything came apart pretty well on the driver side. The rear backing plate was on there pretty good, but a few good hits with a 5lb sledge and it changed its tune.

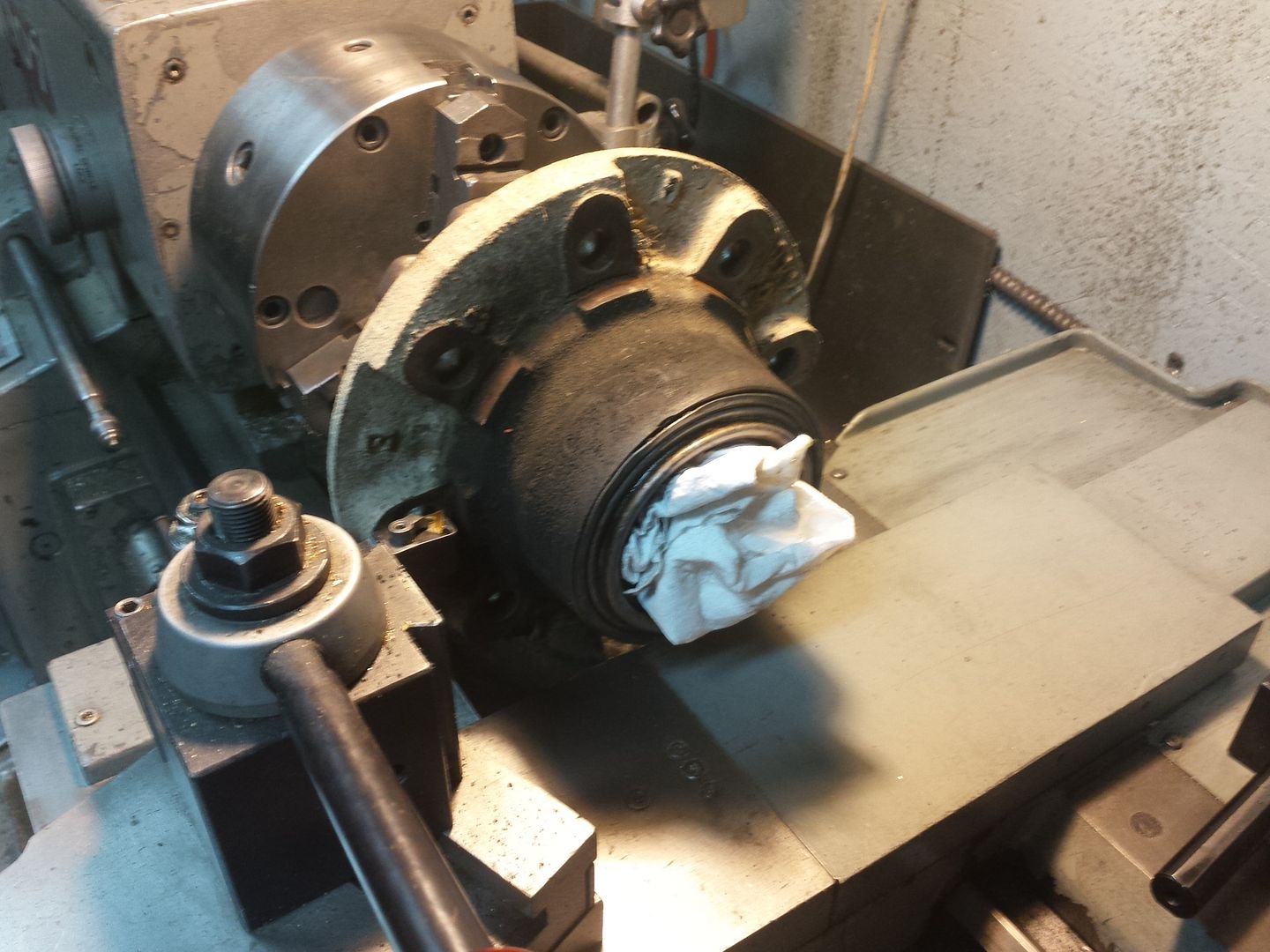

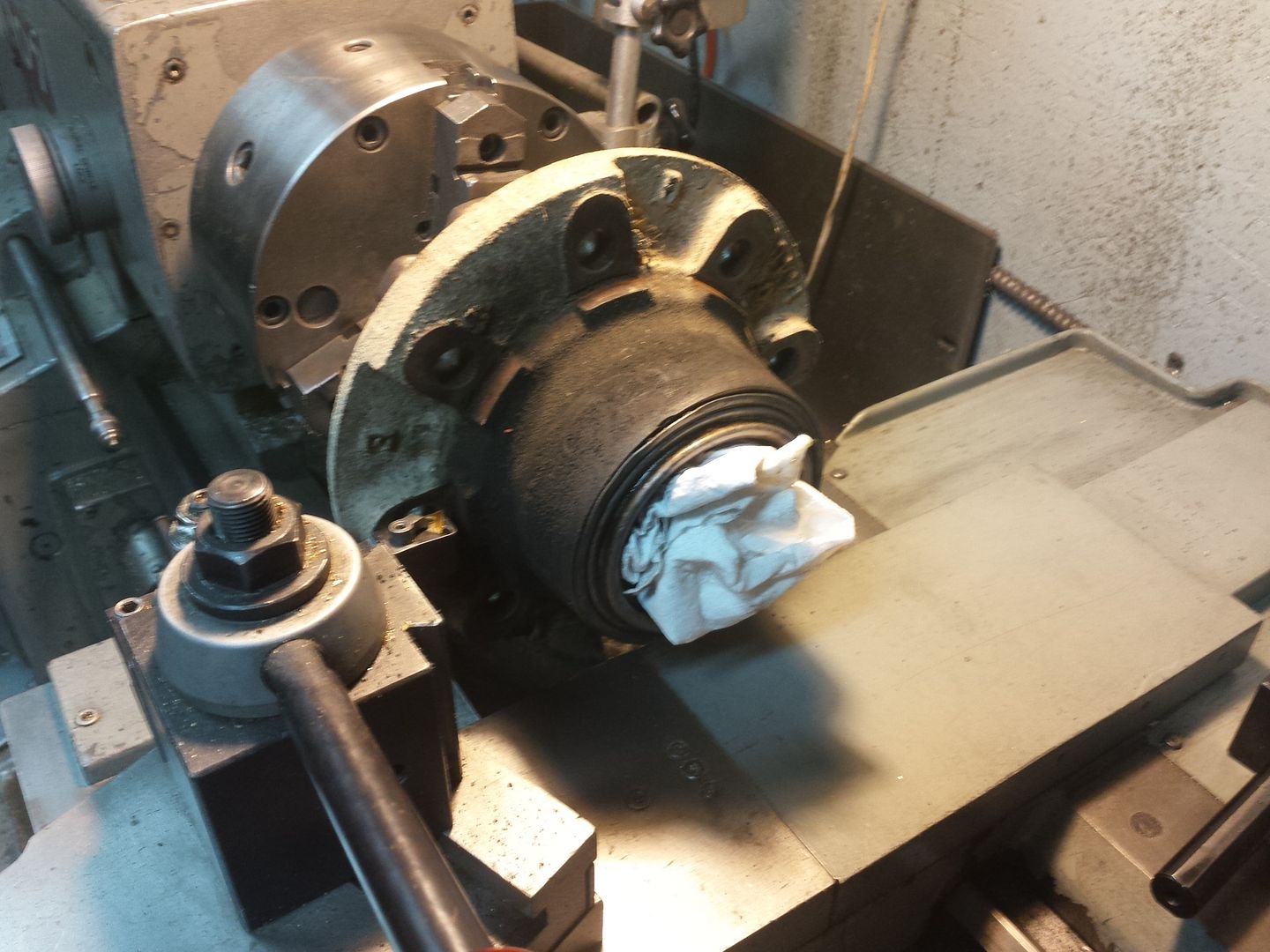

The hubs required a bit of machining to play nicely with the rotors, so the thickness of the flange was brought down to 0.800" from 0.880", and the diameter of the rotor flange was brought from 5.375" down to 5.120".

I opted to do this instead of modifying the rotors, since I want to be able to just buy a rotor and not worry about machining it before install. There is plenty of meat on the hubs so it seemed the obvious choice.

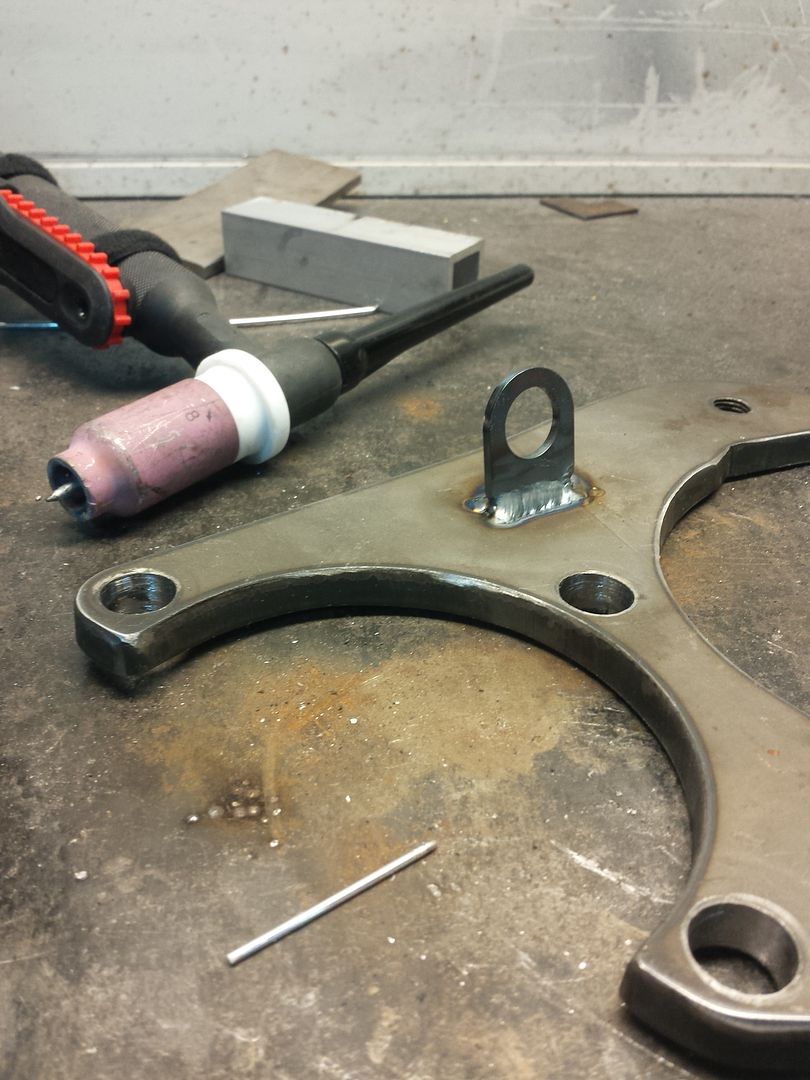

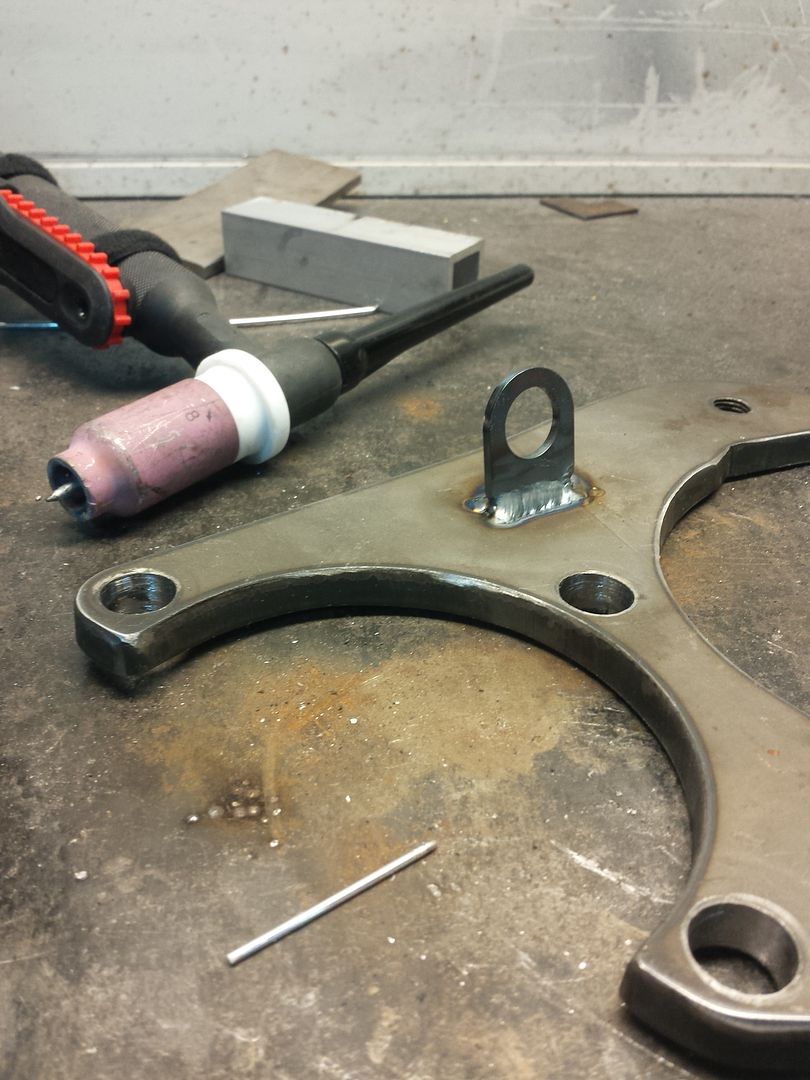

Pre-install of the new components went fine and I was able to locate the new position for the brake hose tabs on the brackets.

After that some paint and final assembly on the driver side.

The hoses I went with are modular braided stainless units with AN-3 fittings on each end. I needed a 7/16" banjo on one end and a 3/16" (3/8 thread) conical on the other end, so this made the most sense. I went with 9" length units which have ended up being a bit on the short side for changing pads. I'll need to get some 12" hoses at some point so I can swap out pads without having to remove the brake hose.

The driver side went about the same except for a blown inner hub axle seal which I needed to swap out. The bearings all around seem to still be in good condition though the inner and outer races on both sides are showing a little "graying" which I suspect means I'll need to address them in the next couple years.

I was able to route the stock brake lines on the axle to their new locations on the caliper brackets without any problem. The axle to frame hose is also new so I could eliminate the stock load sensing rear bias valve (which hasn't actually been doing its job right for...ever?) and install the new proportional balance valve.

I put the valve back over the axle instead of next to the master cylinder mainly because there is no room for a clean install in the engine bay. This is a dirty location for the valve, but it is now set where I want it and I don't plan on adjusting it again any time soon. Everything is anchored so the brake lines themselves aren't experiencing any loading.

After a pretty intensive bleeding, the brakes feel firm and I'd say I've got maybe 10-15% better stopping power now with the stock master cylinder and booster. The new rear calipers do consume more fluid than the original drum slaves, so I do notice the pedal needing more travel for an equivalent brake response.

Phase 3 is likely to occur this week. I'm curious about whether the current master cylinder is actually a 1.125" bore unit. There were 3 available for the 1985 model year, a 1", 1.0625", and 1.125". The only one that SHOULD be installed is the 1.125 but I'm not sure I'm positive that this is the case. If the MC isn't 1.125 I'll replace it with one. If it is, I'll need to start searching for a 1.25" bore unit that can bolt up to my booster without much trouble and has a 3/8" front port and a 7/16" rear port. I know I can adapt if necessary but I'd like it to be a bolt in affair if at all possible.

I know the increase in bore size will drive up pedal effort, but I think a little more master cylinder diameter would be beneficial to overall brake feel.

After that is done and if I still feel the need for more brake response, we need to start talking about a hydroboost system. If I can avoid this I will since it adds complexity that I don't really want, but it is the last thing I can do before having to increase front rotor diameter. If I were to increase the front rotor diameter it would mean an all new tire and wheel package, so costs would clearly start going thru the roof.

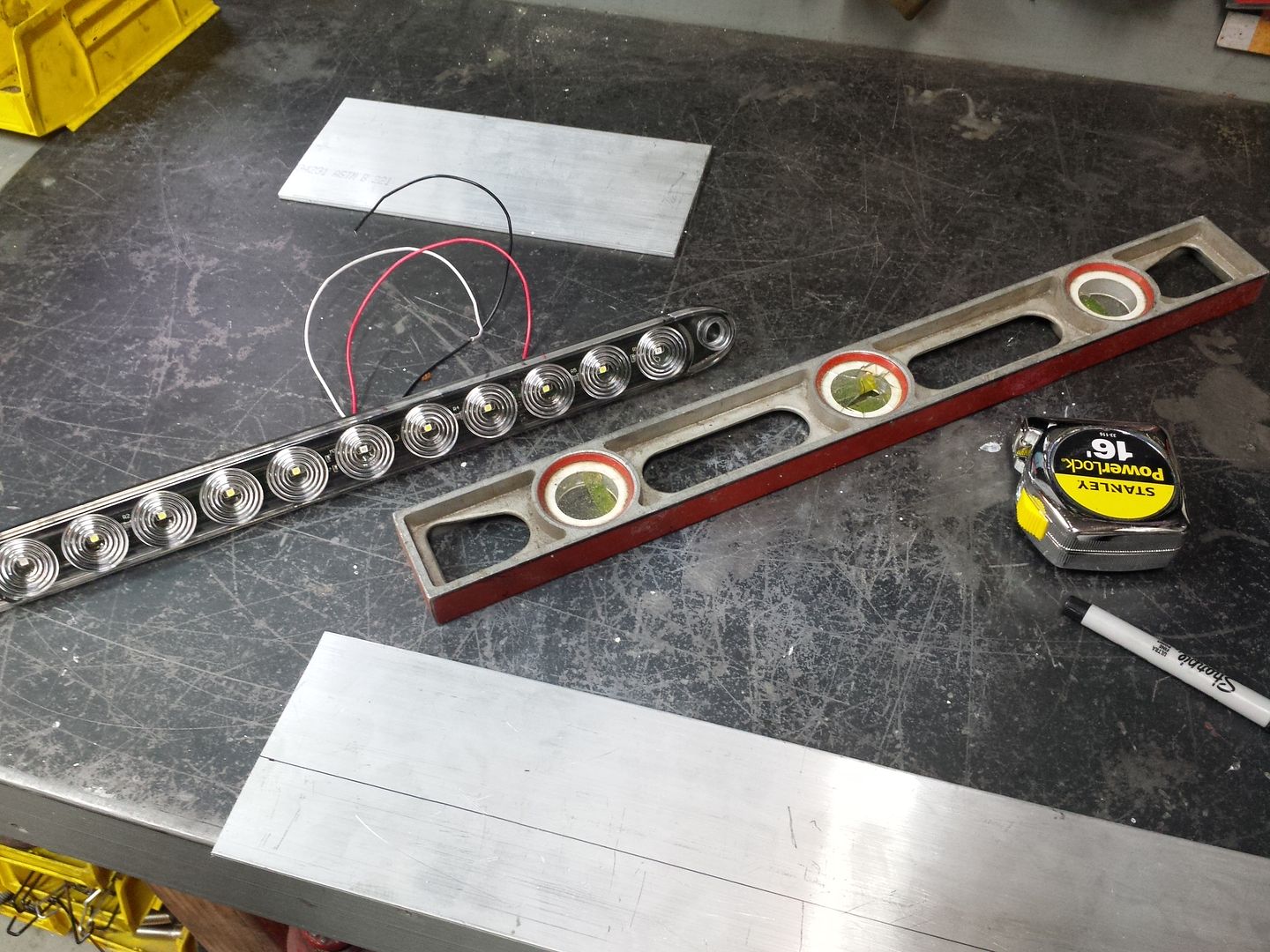

In other news, I just received a new bit of kit from

Blue Ridge Overland Gear. This unit isn't commercially available quite yet but after traveling with Mountain State Overland last month I was able to get one from Matt who owns B.R.O.G. as a test unit. If you have never laid eyes on Blue Ridge stuff, you're really missing out. Everything is hand made and VERY well designed and built. This stuff is heirloom quality overland gear with prices that are totally affordable.

So Boomer has an awesome spare tire trash bag from them now which I love. Rubberized cloth with webbing loops all over it to attach whatever you want to the exterior. It also has a generous velcro loop patch on the flap for sticking your favorite patches to.

I'll be putting all these modifications and upgrades thru some paces on a trip up to the North Maine Woods in a couple weeks and will be reporting back how everything goes.

I need to start working on a positive pressure filtered cabin blower now....not exactly sure how this will go

SG