Get your tickets to THE BIG THING 2026!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Boomer the Quadravan 4x4 Camper

- Thread starter spencyg

- Start date

Wow Boondocker....that is some legit conversion work. I just ripped the suspension out of Boomer this evening and am feeling a little queasy about the whole thing. I wasn't intending to remove the pitman arm (mostly because I HATE removing pitman arms!) but I'm going to need to straighten it a bit for my panhard bar to hit where I want.....so out it came. Post up a few more pics of your front suspension....I'd like to see how you went about it.

Mwilliamshs....I stole the hell out of that idea from another build I saw a long time ago on the interwebs. Plagiarism at its best.

SG

Mwilliamshs....I stole the hell out of that idea from another build I saw a long time ago on the interwebs. Plagiarism at its best.

SG

Mwilliamshs

Explorer

Boondocker, the open area under the crank pulley where the crossmember appears to be made of only a horizontal piece of plate steel...is that boxed-in underneath or triangulated in anyway? The crossmember you pictured has welds in very stress areas. Are they plated underneath or otherwise reinforced? Not being critical, just satisfying some curiosity. I think a picture of the bottom of that crossmember and the engine in-situ from behind would answer both questions. THANKS

Upon arrival this evening from the end of the daily grind I thought it prudent to take a quick drive around the block with Boomer to

A) Make sure the stuff I just build didn't immediately fall off whilst "dynamic"

B) Enjoy actually being under my own power, possibly for the last time, ever.

Because this happened.

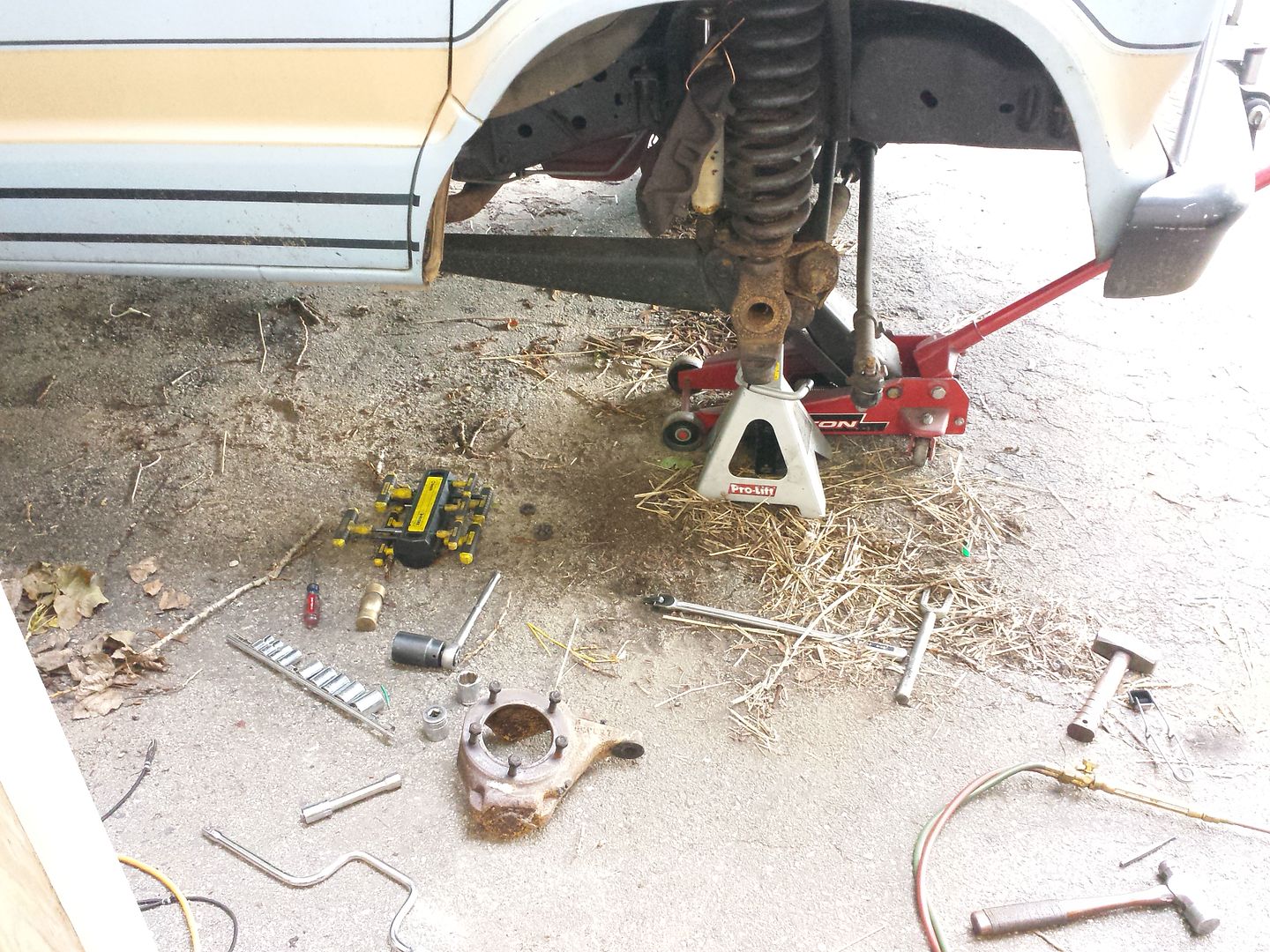

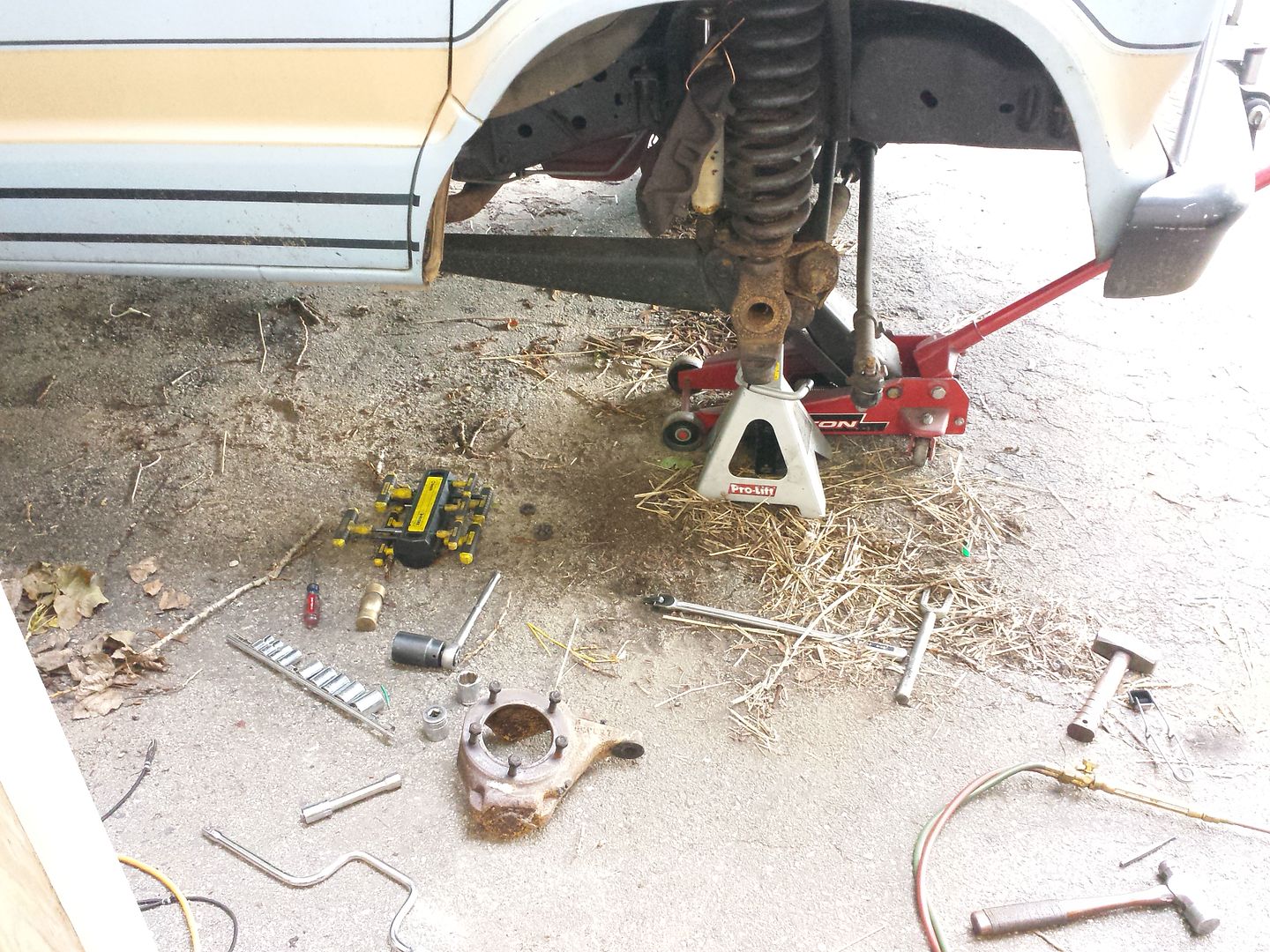

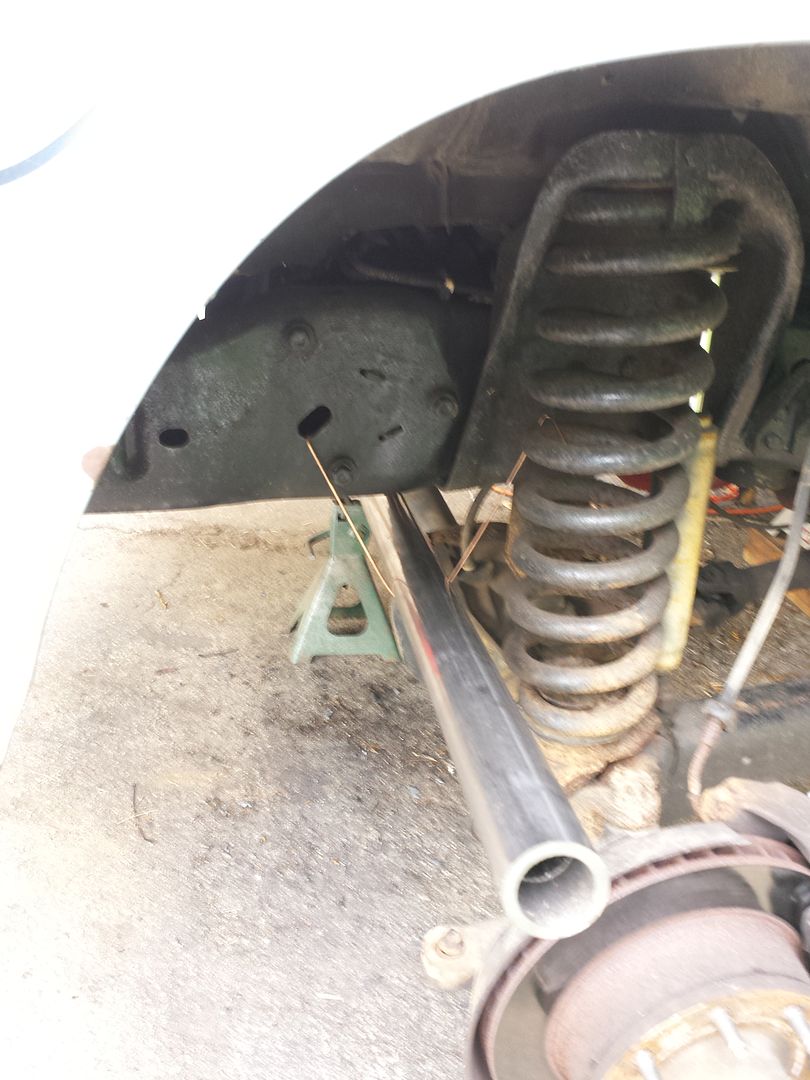

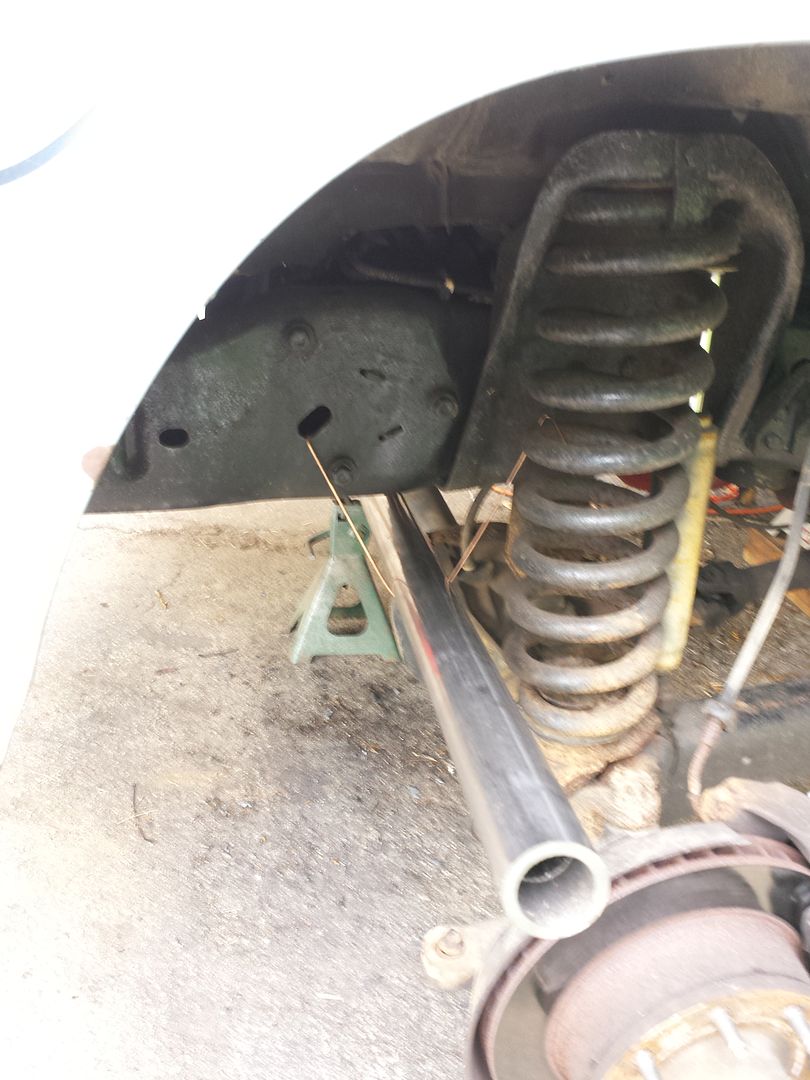

The start of the great pathfinder delete. The hub and knuckle came apart with very little persuasion which surprised me. I have a oxy/acy torch set which gets used maybe half a dozen times a year. Torches are one of those things you need in the rust belt if you're ever going to be successful working on....well....anything.

The parts that came off the driver side look pretty good. A bit of surface rust where you'd expect it, but nothing out of the ordinary.

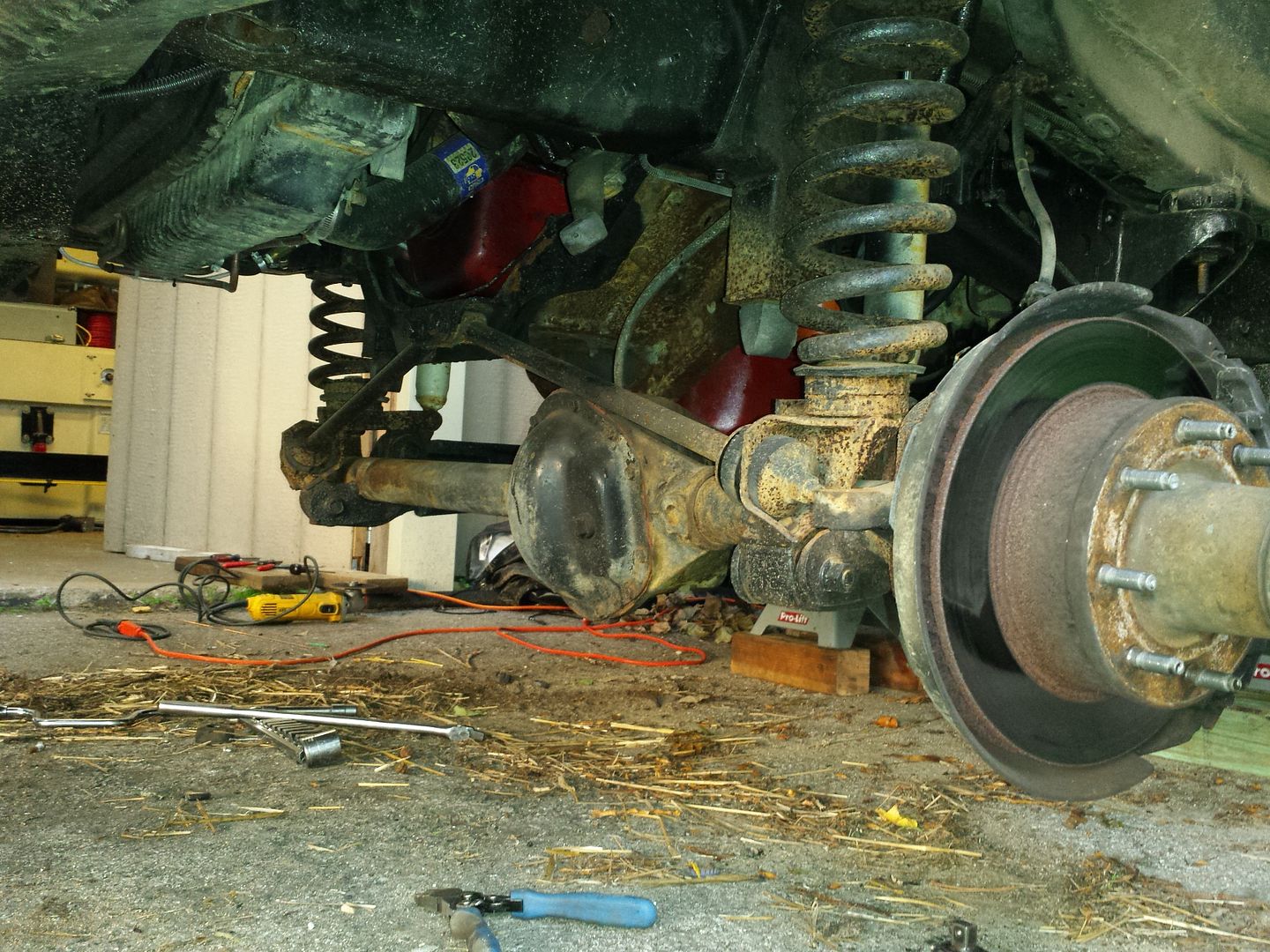

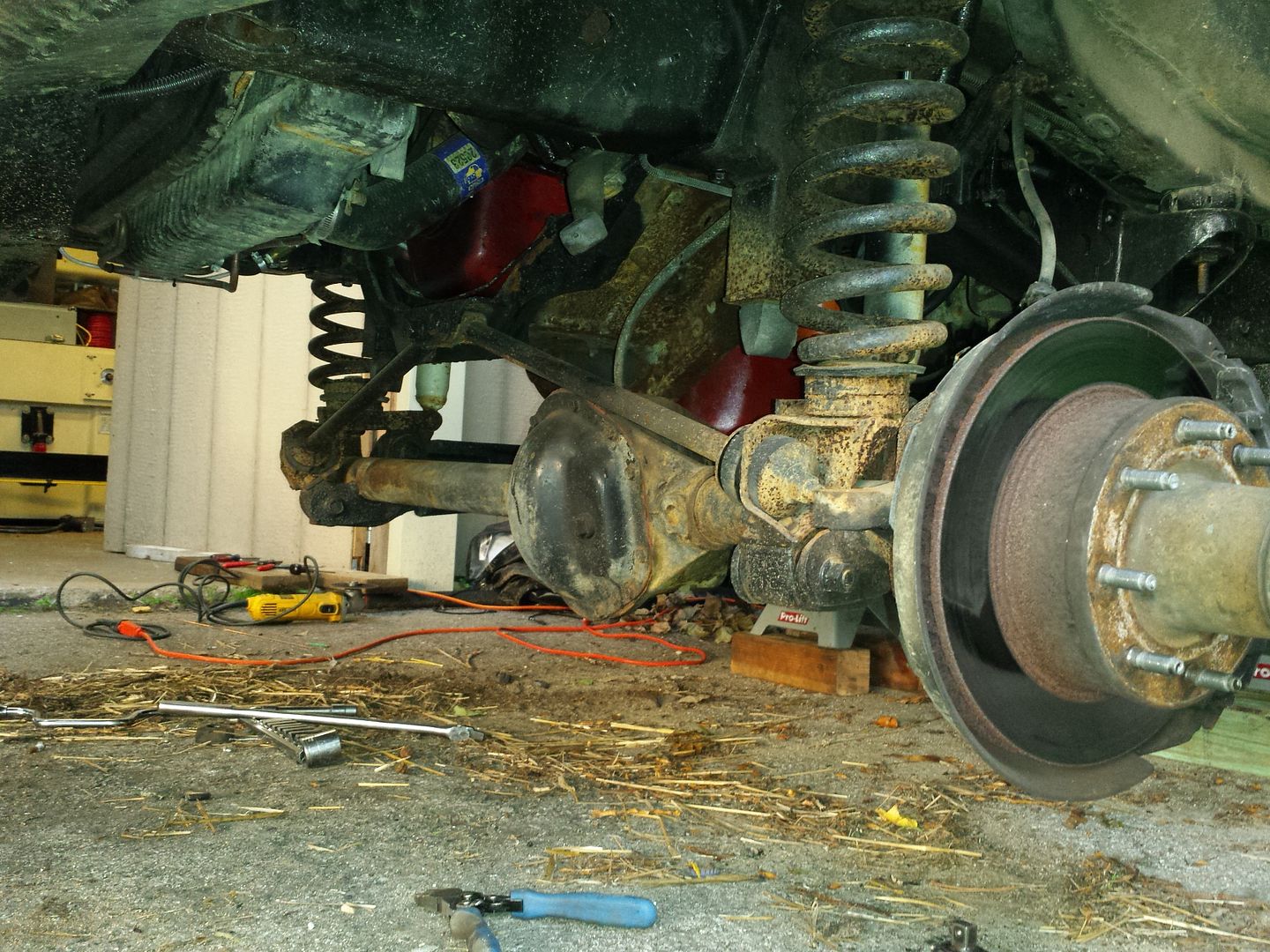

I pulled the steering linkage out so I could get a clear view from all the critical angles of the task ahead. This is one of those "meh...I'll pull everything apart and figure out how to make this work along the way" kind of projects. There is very little plan moving forward. This is your warning.

Removing the passenger hub and knuckle assembly really helped to clarify what kind of challenges lay ahead. With my new ballistic fabrication bushing rod end I was able to "sight the line" between the new perch on the axle, and the new perch on the frame. Unfortunately, the eagle eye view made it very apparent that the pitman arm on the box needs to be bent, twisted, and otherwise modified to allow clearance for the panhard bar.

I hate pitman arms.

I really hate removing pitman arms.

I removed the pitman arm.

Whether the steering box survived the required amount of heat and other forms of persuasion remains to be seen. It is out and future Spencyg can deal with the steering box. I did verify that the threads on the output shaft of the box didn't get mangled as a result of this exercise, so....perfect.

At this point it is dark out.

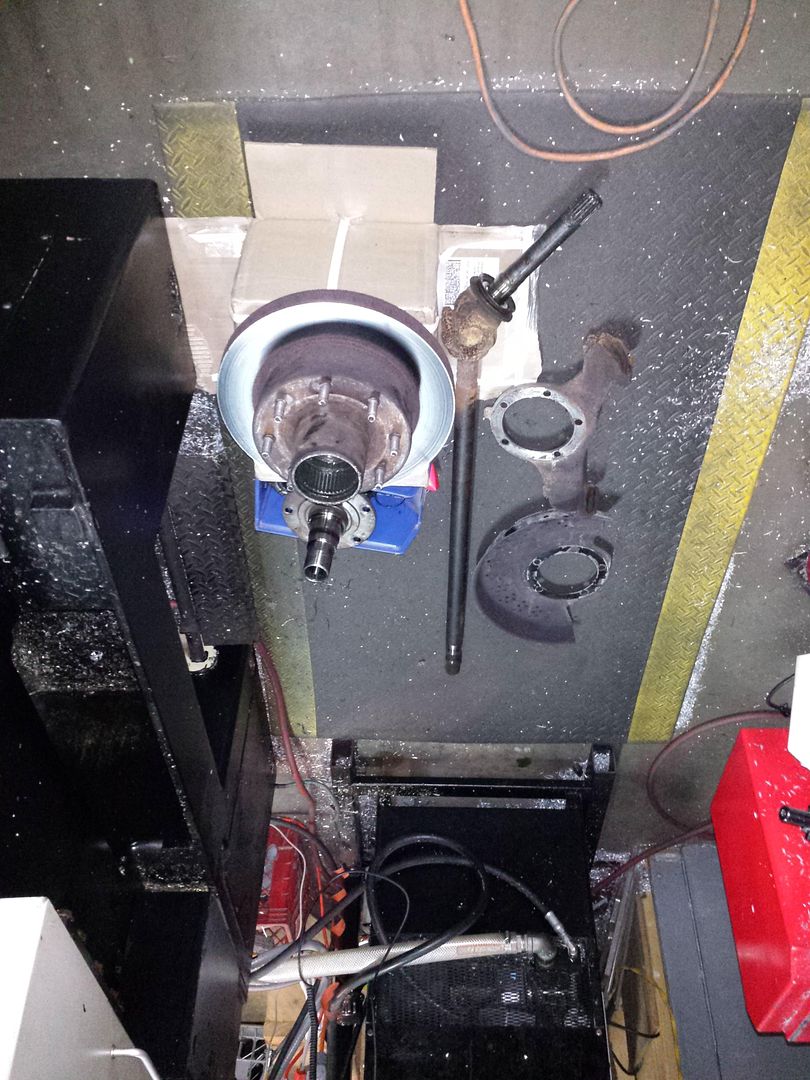

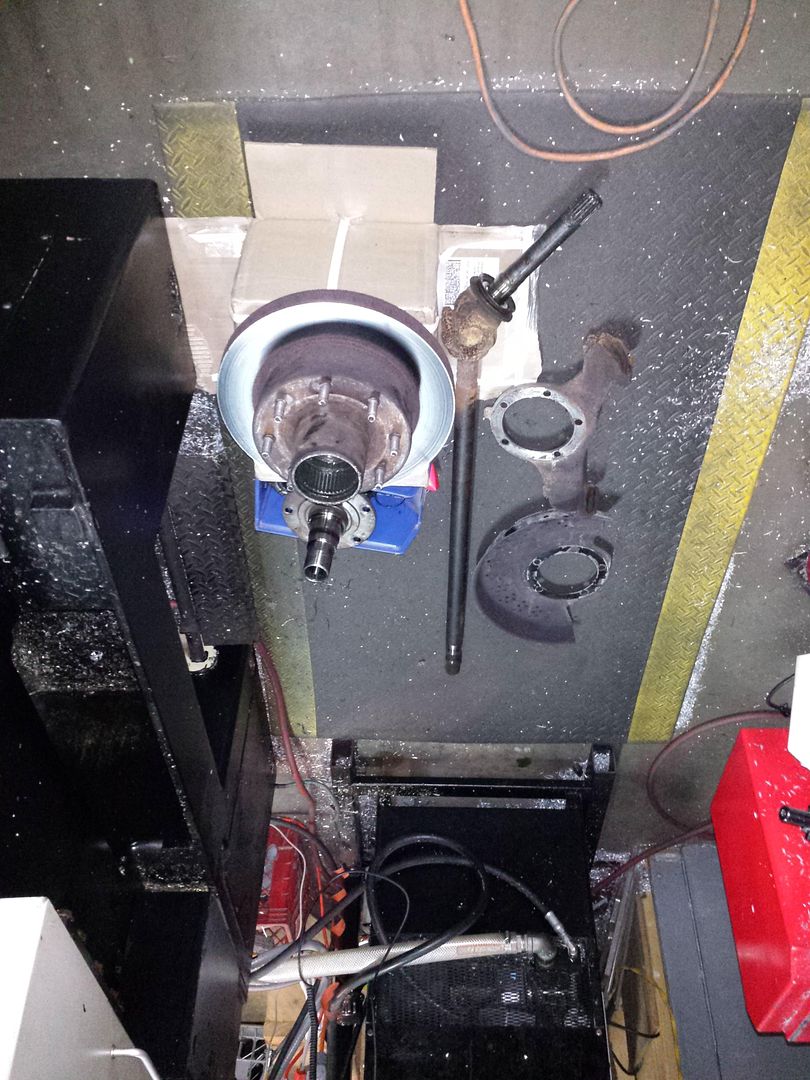

The final task for the evening was heading upstairs to the blast cabinet to descale the brake caliper bracket and the knuckle.

Not bad. Blast cabinets are another thing you use a handful of times a year. They take up a bunch of space, are noisy and dirty, and to the lay person they perform a questionable function. Let me tell you...it is worth every square inch of space it takes up when you need to clean up rusty parts. I actually enjoy the process of media blasting since what you uncover is often times something nobody has laid eyes on in decades. Text and Fine details start popping out of an otherwise indistinguishable plane of filth. A close friend came over last fall with a 100 year old cider press. We started cleaning it up and there were ornate details buried under nearly a century of caked on "stuff". The end result was gorgeous and the cider that came out of that press can't be adequately described. Especially when I let it sit for a few weeks in the sun

Tomorrow morning I need to head to the parts store for a rental balljoint press (overglorified C clamp), some new ball joints, and a slew of GM 1 ton tie rod ends.

It is going to be a long day.

SG

A) Make sure the stuff I just build didn't immediately fall off whilst "dynamic"

B) Enjoy actually being under my own power, possibly for the last time, ever.

Because this happened.

The start of the great pathfinder delete. The hub and knuckle came apart with very little persuasion which surprised me. I have a oxy/acy torch set which gets used maybe half a dozen times a year. Torches are one of those things you need in the rust belt if you're ever going to be successful working on....well....anything.

The parts that came off the driver side look pretty good. A bit of surface rust where you'd expect it, but nothing out of the ordinary.

I pulled the steering linkage out so I could get a clear view from all the critical angles of the task ahead. This is one of those "meh...I'll pull everything apart and figure out how to make this work along the way" kind of projects. There is very little plan moving forward. This is your warning.

Removing the passenger hub and knuckle assembly really helped to clarify what kind of challenges lay ahead. With my new ballistic fabrication bushing rod end I was able to "sight the line" between the new perch on the axle, and the new perch on the frame. Unfortunately, the eagle eye view made it very apparent that the pitman arm on the box needs to be bent, twisted, and otherwise modified to allow clearance for the panhard bar.

I hate pitman arms.

I really hate removing pitman arms.

I removed the pitman arm.

Whether the steering box survived the required amount of heat and other forms of persuasion remains to be seen. It is out and future Spencyg can deal with the steering box. I did verify that the threads on the output shaft of the box didn't get mangled as a result of this exercise, so....perfect.

At this point it is dark out.

The final task for the evening was heading upstairs to the blast cabinet to descale the brake caliper bracket and the knuckle.

Not bad. Blast cabinets are another thing you use a handful of times a year. They take up a bunch of space, are noisy and dirty, and to the lay person they perform a questionable function. Let me tell you...it is worth every square inch of space it takes up when you need to clean up rusty parts. I actually enjoy the process of media blasting since what you uncover is often times something nobody has laid eyes on in decades. Text and Fine details start popping out of an otherwise indistinguishable plane of filth. A close friend came over last fall with a 100 year old cider press. We started cleaning it up and there were ornate details buried under nearly a century of caked on "stuff". The end result was gorgeous and the cider that came out of that press can't be adequately described. Especially when I let it sit for a few weeks in the sun

Tomorrow morning I need to head to the parts store for a rental balljoint press (overglorified C clamp), some new ball joints, and a slew of GM 1 ton tie rod ends.

It is going to be a long day.

SG

Last edited:

Herbie

Rendezvous Conspirator

Holy hell. I've never seen a "real" Pathfinder front setup in that kind of clarity. I've heard it described and seen the drawings, which is one thing, but seeing it "uncovered" like that really shows the wackiness of that design.

Yeah, now I understand why everyone says those things have no suspension travel.

Ooof.

Yeah, now I understand why everyone says those things have no suspension travel.

Ooof.

Yeah...I don't know what they were thinking. But I know what I'm thinking! (sortof)

The day started at 5am when my brain turned on and told me to get up and at it.

So what to do at 5am while the neighbors are still sleeping.

Torches are quiet. I'll torch.

Oooh. Plasma cutters are quiet.

I'll cut.

I eliminated the brackets on each side down on the axle as well as the bracket on the crossmember. There was actually quite a bit of material to burn through up there and I ended up with a rather ominous hole.

No bother. The plan than I don't have totally accounted for this.

While I was chopping with the plasma hatchet I decided it prudent to open up clearance a whisker above the front pumpkin. The intention for all the removals in the crossmember was to give myself a little breathing room for the panhard bar. When lining everything up by eye things were looking very....close.

Once I was done burning myself on the asphalt I decided it would be good to burn myself inside for a bit.

I got out the oxy/acy torch again and went to town straightening the pitman arm. Fear not...I followed the book. The arm is forged and can be bent very safely when you heat to the required temperature, continue applying heat while bending, and then cool very slowly in a bucket of sand. I took about 8 degrees out of the upper bend which should put everything in good alignment.

During the cooling process I ran out to get tie rod ends, ball joints, and some bolts.

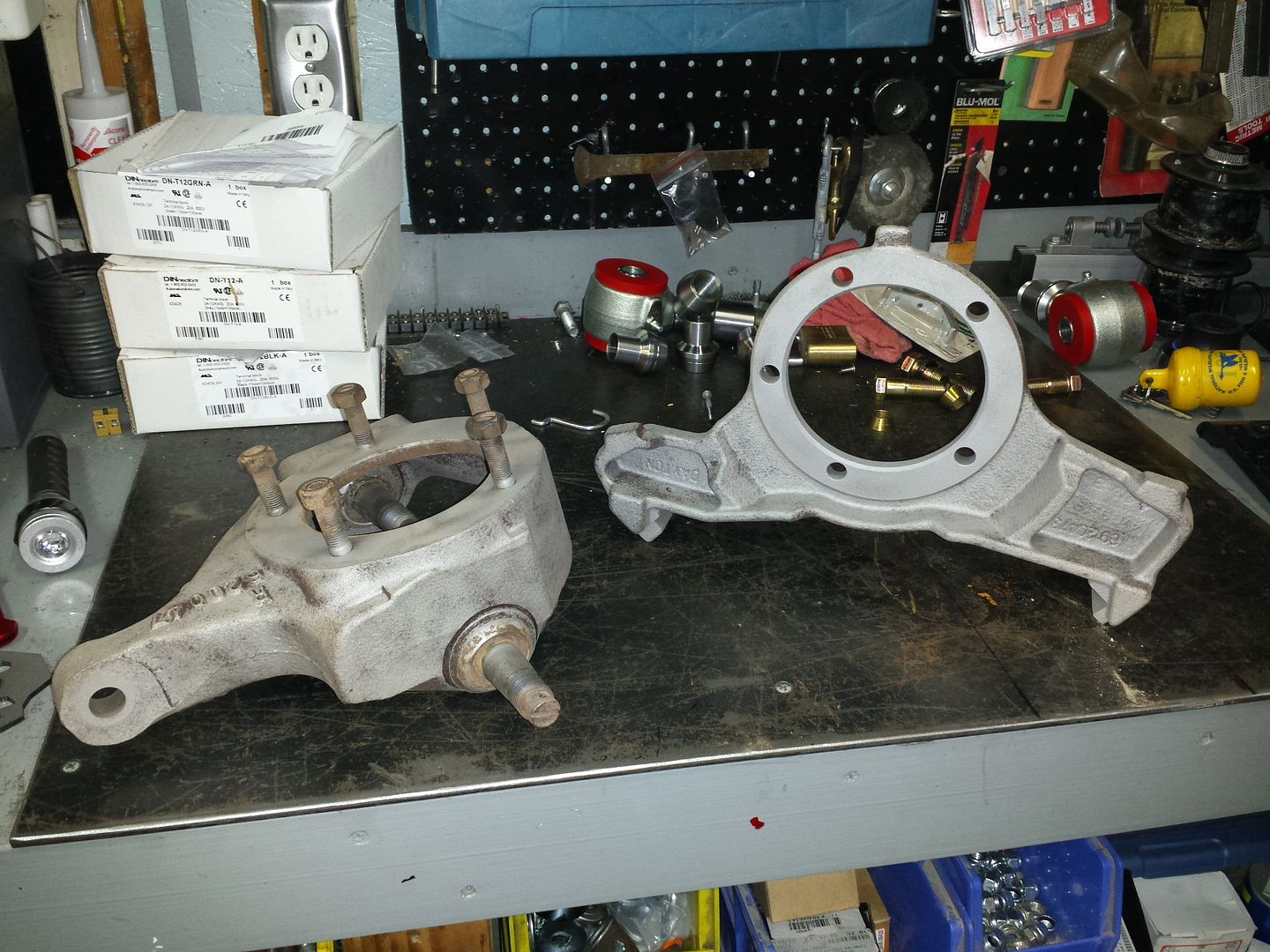

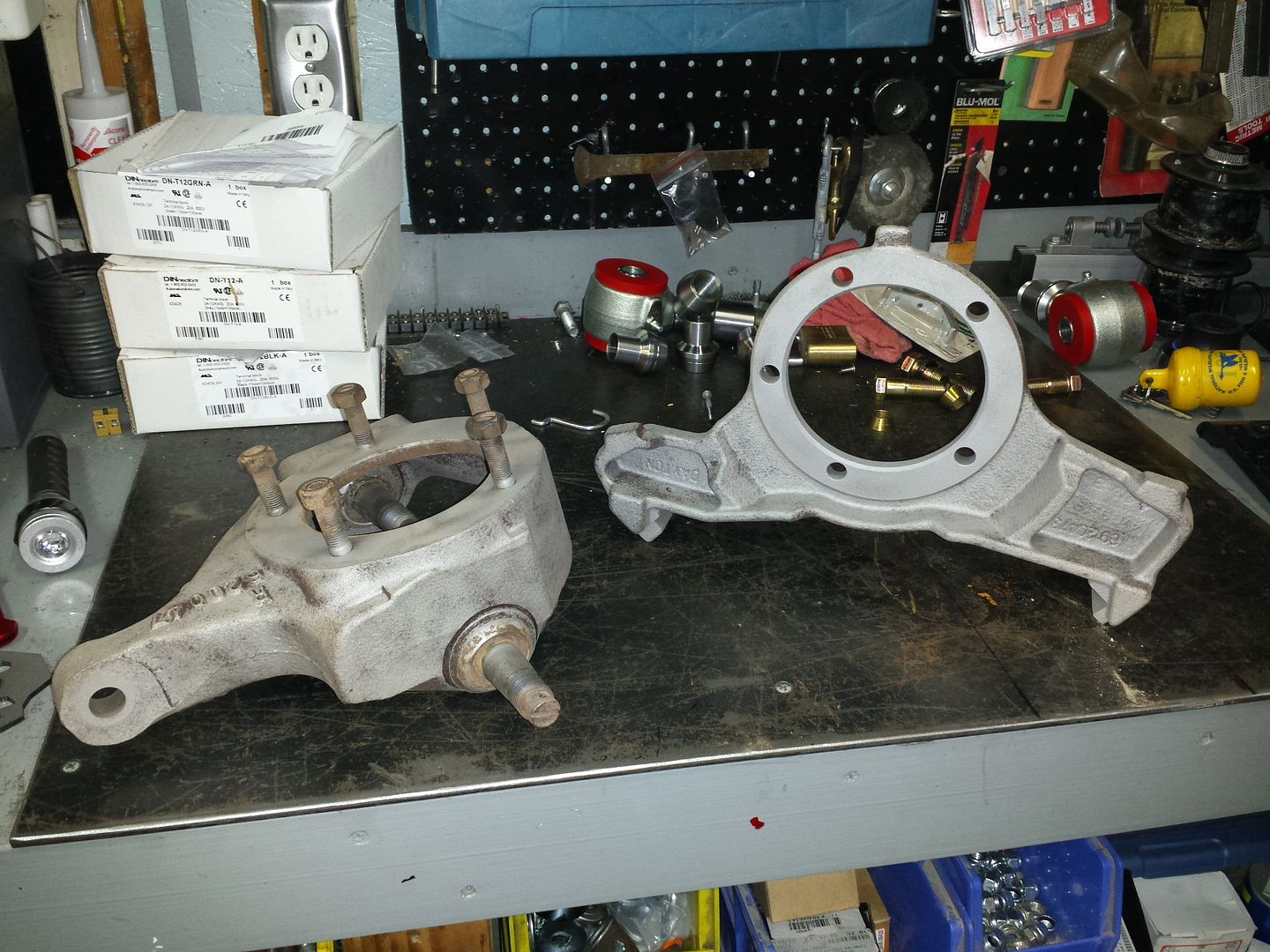

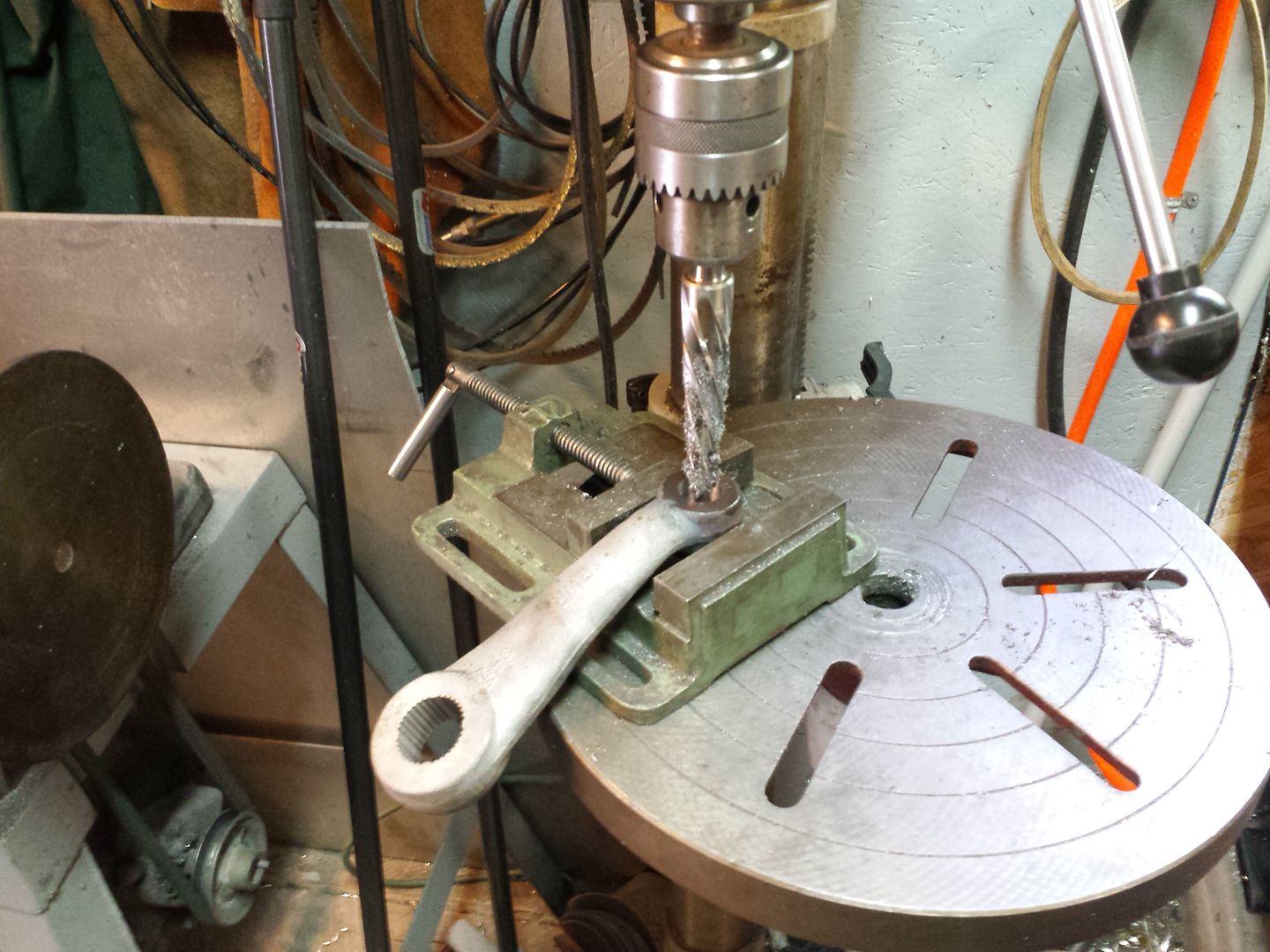

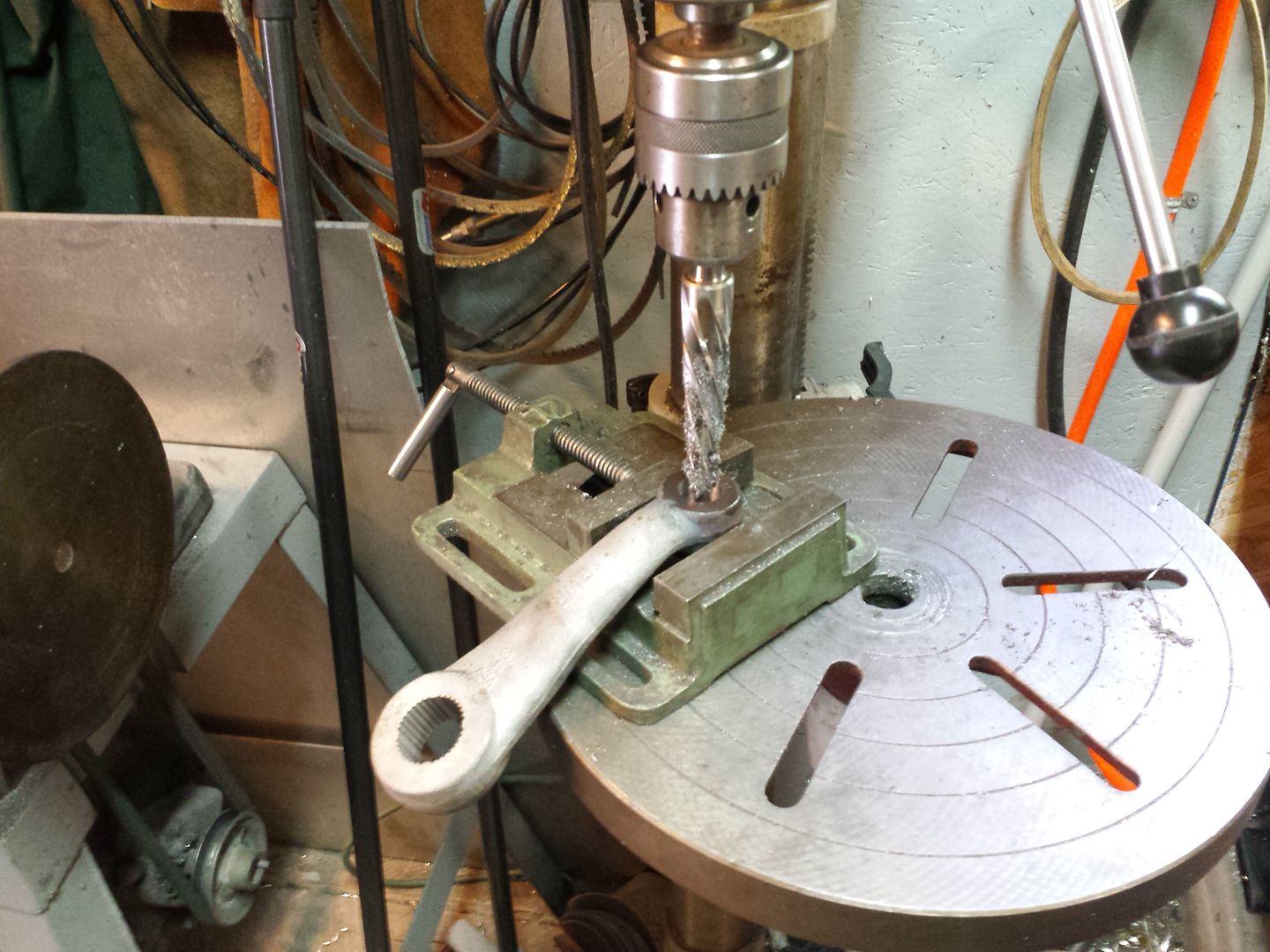

Upon return I fired up the mill and surfaced the top of the knuckle for the high steer arm. I also drilled and tapped the casting for the 9/16-18 bolts.

Once that was complete I broke out the 7 degree taper reamer to enlarge the tie rod end hole in the pitman as well as bore and ream a hole in the high steer arm.

And threw the rest of the knuckle back together.

By now grinding in the driveway wasn't going to bother anybody so I set to work cleaning up the hatchet wounds from earlier in the morning.

I needed to add a new flange to the areas of the crossmember which were originally cut by Pathfinder Industries and then again by myself. A few pieces of 1/4" x 1-1/4" steel bar made quick work of the repairs and the clearancing performed earlier really "started to pop" I probably gained almost an inch which is huge with these vans.

Unfortunately, I don't have specific pictures of the steel work. You'll see them in a few upcoming pics.

At this point I was itching to actually add in a piece of suspension linkage so I started in on the panhard bar mount on the axle. The stock mount has space behind the front plate for a welded nut so after a 3/4" steel spacer to get the the bushing out far enough for clearance. I still tried to keep it as close as possible to minimize the moment arm on the assembly.

The mount is not complete yet as the final assembly will be in double sheer. I've allowed enough space for an outboard plate and don't expect any interference issues.

The opposite end of the panhard bar won't be mounted until the steering linkages are attached. Getting the panhard bar and drag link parallel and of nearly equal length is critical to prevent bump-steer. I can adjust the frame mounted end of the panhard bar position but I can't adjust the steering box position, so the frame end mount is the very last part to be fabricated. Also, not the new steel flange following along the bottom of the crossmember. I'll try and take a better pic tomorrow.

The opposite end of the panhard tube is supported by the most ghetto means I could devise....fabulous.

While all of this was going on I kept up on primer and paint for the knuckle assembly as well as a few other parts.

And then, right before closing up for the day, I applied my new sticker.

The shop was a disaster, I was a mess....it was time to call it a day.

SG

The day started at 5am when my brain turned on and told me to get up and at it.

So what to do at 5am while the neighbors are still sleeping.

Torches are quiet. I'll torch.

Oooh. Plasma cutters are quiet.

I'll cut.

I eliminated the brackets on each side down on the axle as well as the bracket on the crossmember. There was actually quite a bit of material to burn through up there and I ended up with a rather ominous hole.

No bother. The plan than I don't have totally accounted for this.

While I was chopping with the plasma hatchet I decided it prudent to open up clearance a whisker above the front pumpkin. The intention for all the removals in the crossmember was to give myself a little breathing room for the panhard bar. When lining everything up by eye things were looking very....close.

Once I was done burning myself on the asphalt I decided it would be good to burn myself inside for a bit.

I got out the oxy/acy torch again and went to town straightening the pitman arm. Fear not...I followed the book. The arm is forged and can be bent very safely when you heat to the required temperature, continue applying heat while bending, and then cool very slowly in a bucket of sand. I took about 8 degrees out of the upper bend which should put everything in good alignment.

During the cooling process I ran out to get tie rod ends, ball joints, and some bolts.

Upon return I fired up the mill and surfaced the top of the knuckle for the high steer arm. I also drilled and tapped the casting for the 9/16-18 bolts.

Once that was complete I broke out the 7 degree taper reamer to enlarge the tie rod end hole in the pitman as well as bore and ream a hole in the high steer arm.

And threw the rest of the knuckle back together.

By now grinding in the driveway wasn't going to bother anybody so I set to work cleaning up the hatchet wounds from earlier in the morning.

I needed to add a new flange to the areas of the crossmember which were originally cut by Pathfinder Industries and then again by myself. A few pieces of 1/4" x 1-1/4" steel bar made quick work of the repairs and the clearancing performed earlier really "started to pop" I probably gained almost an inch which is huge with these vans.

Unfortunately, I don't have specific pictures of the steel work. You'll see them in a few upcoming pics.

At this point I was itching to actually add in a piece of suspension linkage so I started in on the panhard bar mount on the axle. The stock mount has space behind the front plate for a welded nut so after a 3/4" steel spacer to get the the bushing out far enough for clearance. I still tried to keep it as close as possible to minimize the moment arm on the assembly.

The mount is not complete yet as the final assembly will be in double sheer. I've allowed enough space for an outboard plate and don't expect any interference issues.

The opposite end of the panhard bar won't be mounted until the steering linkages are attached. Getting the panhard bar and drag link parallel and of nearly equal length is critical to prevent bump-steer. I can adjust the frame mounted end of the panhard bar position but I can't adjust the steering box position, so the frame end mount is the very last part to be fabricated. Also, not the new steel flange following along the bottom of the crossmember. I'll try and take a better pic tomorrow.

The opposite end of the panhard tube is supported by the most ghetto means I could devise....fabulous.

While all of this was going on I kept up on primer and paint for the knuckle assembly as well as a few other parts.

And then, right before closing up for the day, I applied my new sticker.

The shop was a disaster, I was a mess....it was time to call it a day.

SG

Last edited:

I was able to steal away a couple hours this afternoon to finish up the axle side panhard mount.

It is very solid and everything is aligned as I want it. Next steps are steering linkages.

And for a little more detail on modifications to the engine crossmember.

I degreased and pressure washed the axle and frame members before calling it a day. Tomorrow I'll get the metal primed and painted so that everything can push forward without any need to "back up" for paint as everything comes together.

SG

It is very solid and everything is aligned as I want it. Next steps are steering linkages.

And for a little more detail on modifications to the engine crossmember.

I degreased and pressure washed the axle and frame members before calling it a day. Tomorrow I'll get the metal primed and painted so that everything can push forward without any need to "back up" for paint as everything comes together.

SG

Desert Dan

Explorer

Nice work. We don't see rust like that out here in So. CA

seeing it "uncovered" like that really shows the wackiness of that design.

Yeah, now I understand why everyone says those things have no suspension travel.

Ooof.

+1

Campbulance

Observer

Just read through this thread. You are quite handy with the welder, and CNC machines. Just two comments. Show a pic of the Supra again if you still have it. I have a 89 Turbo in the garage as well. They are cool cars albeit problematic with their head gaskets. Also, I would suggest painting the Boomer logo to make it pop some more.

The Supra is long gone....I don't have enough money kicking around to support 2 problem children

The Boomer logo getting painted has been suggested by many. Someday I might do it, but it is kind of a test when people walk up to Boomer to see how closely they are paying attention. Most folks don't even notice it.

I didn't get a whole lot accomplished on Sunday. I was able to get a coat of rust catalyst and a coat of primer on the axle and surrounding surfaces, and got up early this morning to apply a coat of semi-gloss black. This should keep things from rusting up too badly for awhile.

Tonight I'll start in on steering linkages. I hope to have everything back together and rolling down the road by Friday.

SG

The Boomer logo getting painted has been suggested by many. Someday I might do it, but it is kind of a test when people walk up to Boomer to see how closely they are paying attention. Most folks don't even notice it.

I didn't get a whole lot accomplished on Sunday. I was able to get a coat of rust catalyst and a coat of primer on the axle and surrounding surfaces, and got up early this morning to apply a coat of semi-gloss black. This should keep things from rusting up too badly for awhile.

Tonight I'll start in on steering linkages. I hope to have everything back together and rolling down the road by Friday.

SG

Mwilliamshs

Explorer

I may have overlooked it but I kinda doubt it, I've read this whole thread so many times I can click on the right page number for whatever I'm looking for, are you hoping to get more articulation from these mods (trim the bumpstops)?

The intent of the project wasn't to gain articulation, and only after it was all cut apart did the opportunity to provide more clearance between the pumpkin and cross member present itself. The bumpstops are (for good reason) the limiting factor in bump travel and will remain so for the time being. Once everything is back together and the front springs are supporting weight again it will be clear whether I can gain anything safely with cutting off the current bumpstops and fabricating something a little shorter to allow a little more upward travel. I'd really like a pair of these hydraulic bump stops and may do it eventually....my budget is so remarkably blown on the projects this summer that it will have to wait.

Something else to note is that the front suspension portion of this build thread relates directly to the Pathfinder front suspension discussion here in the camper van section of ExPo. It is a really good read for those curious about the pathfinder suspension.

SG

Something else to note is that the front suspension portion of this build thread relates directly to the Pathfinder front suspension discussion here in the camper van section of ExPo. It is a really good read for those curious about the pathfinder suspension.

SG

Last edited:

Steering linkages started coming together last night but it was late, I didn't accomplish much, thus I have no pictures. The low-down skinny on the situation is as follows:

1) The crossover link barely clears the panhard bar mount, but 1/16" is a mile here so no problem.

2) The drag link is basically flat which would normally be great.

3) The panhard bar is not flat which makes (2) not great.

The problem here is that the panhard mount on the axle can't move up because of the location of the coil spring and associated hardware. I did re-bend the pitman arm last night to get the steering box end of the drag link as high in the frame as possible / reasonable.

The implications of all this, given the absolute requirement to have the drag link and panhard link parallel, is to lower the frame end mount for the panhard bar or remove the high steer arm for the drag link.

If the high steer arm was removed I could possibly get away with an ES2233L link and incorporate the drag link connection into the crossover bar connection. Clearance to the panhard mount on the frame could be an issue with this solution.

I'm going to pick up on ES2233L this afternoon and mock up a couple different scenarios. If I could remove the high steer arm out of the equation I think this would be the best overall solution.

After that series of unfortunate realizations, I went back in where there was light and finished up the front flashlight / 2 way radio organizer.

I'll mount that on the front of the engine box to put these items in easy reach.

I finished up the evening with the propane manifold complete with a quick disconnect, and a secondary quick disconnect hose which has a 1 lb propane bottle adapter on the end. I'll be able to use this quick disconnect hose to run the propane grill as well as any other accessories we might happen upon which rely on 1 lb propane bottles.

I'll grab some photos of the linkages all in place tonight to provide a bit more clarity to the linkage issues.

SG

1) The crossover link barely clears the panhard bar mount, but 1/16" is a mile here so no problem.

2) The drag link is basically flat which would normally be great.

3) The panhard bar is not flat which makes (2) not great.

The problem here is that the panhard mount on the axle can't move up because of the location of the coil spring and associated hardware. I did re-bend the pitman arm last night to get the steering box end of the drag link as high in the frame as possible / reasonable.

The implications of all this, given the absolute requirement to have the drag link and panhard link parallel, is to lower the frame end mount for the panhard bar or remove the high steer arm for the drag link.

If the high steer arm was removed I could possibly get away with an ES2233L link and incorporate the drag link connection into the crossover bar connection. Clearance to the panhard mount on the frame could be an issue with this solution.

I'm going to pick up on ES2233L this afternoon and mock up a couple different scenarios. If I could remove the high steer arm out of the equation I think this would be the best overall solution.

After that series of unfortunate realizations, I went back in where there was light and finished up the front flashlight / 2 way radio organizer.

I'll mount that on the front of the engine box to put these items in easy reach.

I finished up the evening with the propane manifold complete with a quick disconnect, and a secondary quick disconnect hose which has a 1 lb propane bottle adapter on the end. I'll be able to use this quick disconnect hose to run the propane grill as well as any other accessories we might happen upon which rely on 1 lb propane bottles.

I'll grab some photos of the linkages all in place tonight to provide a bit more clarity to the linkage issues.

SG

Last edited:

Mwilliamshs

Explorer

I don't like that 2233L for a couple of reasons.

Chief among them is that that particular part number is for the driver's side (note the L) so the threads will probably not work on your passenger side of the tie rod (although in lots of applications they are the same left to right, if so, disregard). I didn't look but I bet there's a passenger side part too. Not to mention that that part places the stresses of the tie rod (connecting one wheel to another for directional changes/control) and the draglink (transferring force from the steering gear to the wheels) ALL on 1 set of threads. If you're using the stock stamped threaded adjusters with pinch bolts, etc I'd really really really not like to see that considering the weight of the vehicle, the width and tread of the tires (lots of scrub), and that the vehicle sees use both off-road (high-stress + dangerous terrain [like driving off a cliff, to be extreme]) and on the highway (high-speed + danger to others [like a head-on collision to be extreme]). If you really want to use the ES2233L part I would suggest a tie-rod made from stong tubing with weld-in threaded bungs. This will eliminate the junky threaded adjusters and make for a stronger part overall. Should be easy-peasy given your skill set!

Secondly, the high-steer arm keeps the draglink up higher and out of harms way so I'd prefer keeping it. It may also provide better leverage OR a better turning radius. Something to consider.

Thirdly, I think you've made the best of things on the axle end. It looks solid, strong, and simple. I would lower the panhard mount and brace it from the passenger frame rail and keep on moving with the build. Not like you're facing a lot of bump-steer inducing wheel travel anyway so a good ~8" of acceptable motion should be easy to obtain. (that figure is probably optimistic considering the pictures above show full droop (except the weight of the tires/wheels) and there's maybe 7" between bumpstop and axle according to my VERY inaccurate eyeballs) (assuming 3" axle tubes for estimation by comparison)

After bending the pitman arm twice, no matter how careful, I'd replace it. That one part is a MAJOR part and I think you could not only improve safety but also choose something more perfectly matched to your application, and probably find a happier-medium between panhard and drag link angles. Since it's been on and off recently it should come off easily!

Chief among them is that that particular part number is for the driver's side (note the L) so the threads will probably not work on your passenger side of the tie rod (although in lots of applications they are the same left to right, if so, disregard). I didn't look but I bet there's a passenger side part too. Not to mention that that part places the stresses of the tie rod (connecting one wheel to another for directional changes/control) and the draglink (transferring force from the steering gear to the wheels) ALL on 1 set of threads. If you're using the stock stamped threaded adjusters with pinch bolts, etc I'd really really really not like to see that considering the weight of the vehicle, the width and tread of the tires (lots of scrub), and that the vehicle sees use both off-road (high-stress + dangerous terrain [like driving off a cliff, to be extreme]) and on the highway (high-speed + danger to others [like a head-on collision to be extreme]). If you really want to use the ES2233L part I would suggest a tie-rod made from stong tubing with weld-in threaded bungs. This will eliminate the junky threaded adjusters and make for a stronger part overall. Should be easy-peasy given your skill set!

Secondly, the high-steer arm keeps the draglink up higher and out of harms way so I'd prefer keeping it. It may also provide better leverage OR a better turning radius. Something to consider.

Thirdly, I think you've made the best of things on the axle end. It looks solid, strong, and simple. I would lower the panhard mount and brace it from the passenger frame rail and keep on moving with the build. Not like you're facing a lot of bump-steer inducing wheel travel anyway so a good ~8" of acceptable motion should be easy to obtain. (that figure is probably optimistic considering the pictures above show full droop (except the weight of the tires/wheels) and there's maybe 7" between bumpstop and axle according to my VERY inaccurate eyeballs) (assuming 3" axle tubes for estimation by comparison)

After bending the pitman arm twice, no matter how careful, I'd replace it. That one part is a MAJOR part and I think you could not only improve safety but also choose something more perfectly matched to your application, and probably find a happier-medium between panhard and drag link angles. Since it's been on and off recently it should come off easily!

Last edited:

Similar threads

- Replies

- 1

- Views

- 375

- Replies

- 16

- Views

- 3K

- Replies

- 1

- Views

- 639

- Replies

- 1

- Views

- 815