I'm with ya on the 2233L...the more I look at it the less I like it. I'll keep on track with the current high steer arm.

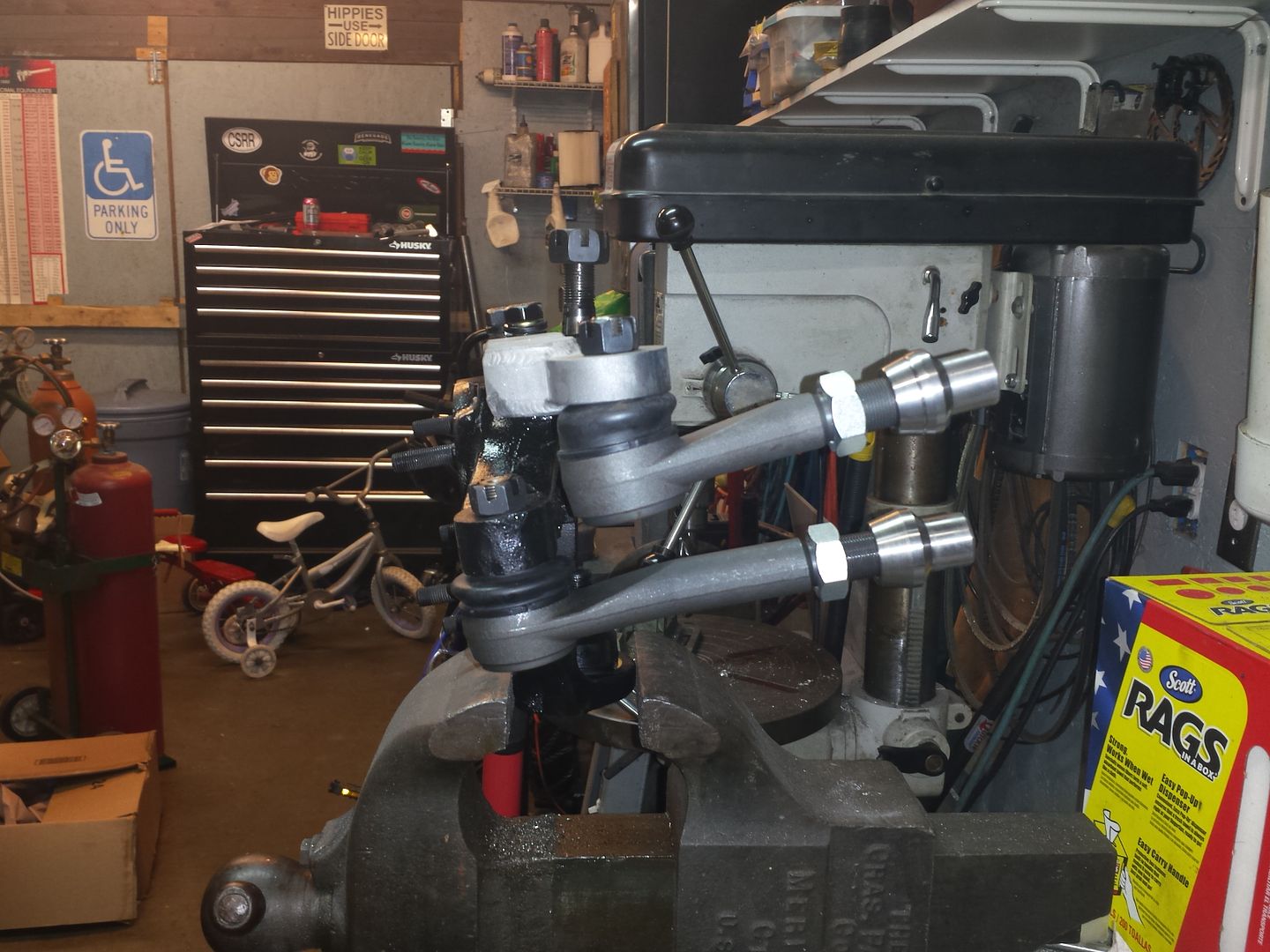

As for the pitman...the controversy that surrounds the modification of these things is pretty large. You read some folks who are against using anything other than brand new unmodified arms, and other folks who put the heat to it without any problems at all.

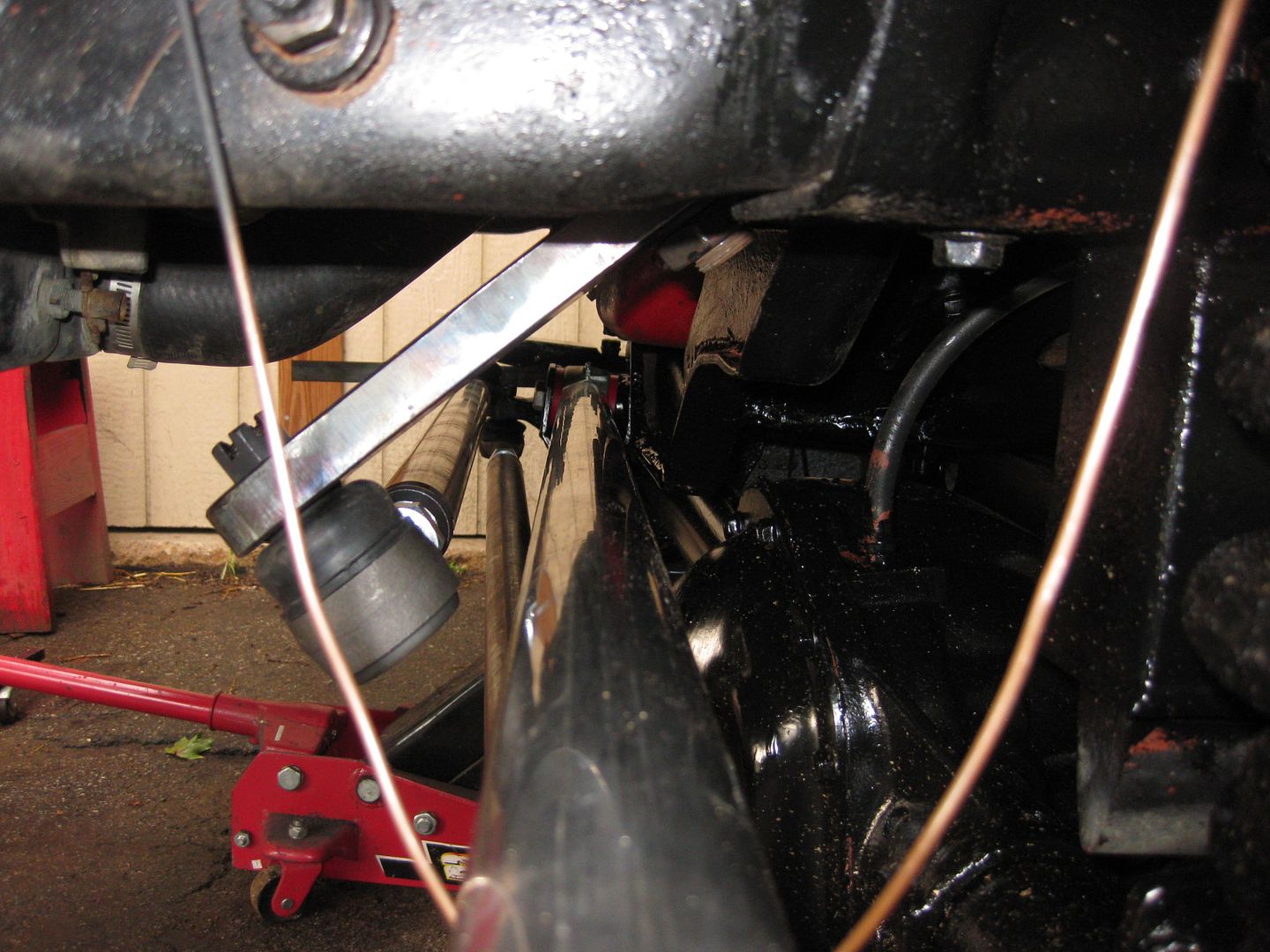

I am an engineer by both education and trade...some of my time has been spent doing metallurgical testing and from my point of view properly heated forged steel should be fine to bend if the original forging was good to begin win. This particular arm I'm working with is original equipment and has held up fine so far. I heated to the required temperature both times, bent while still applying the correct amount of heat, then slowly cooled the unit overnight in a bucket of sand.

That being said, I'm going to weld (remember, we're dealing with forged steel here) some additional reinforcement to the arm this afternoon before re-assembly to provide an additional level of insurance. Do I think I need it? No. Am I going to do it anyway? Yes.

Any arm I buy wouldn't be what I need so regardless of what the "correct" path forward is, I'd end up heating and bending whatever showed up. This arm is time tested and proven crack free this far. Anything else that would arrive in the mail (used for sure, new possibly) would be a questionable start.....

SG

As for the pitman...the controversy that surrounds the modification of these things is pretty large. You read some folks who are against using anything other than brand new unmodified arms, and other folks who put the heat to it without any problems at all.

I am an engineer by both education and trade...some of my time has been spent doing metallurgical testing and from my point of view properly heated forged steel should be fine to bend if the original forging was good to begin win. This particular arm I'm working with is original equipment and has held up fine so far. I heated to the required temperature both times, bent while still applying the correct amount of heat, then slowly cooled the unit overnight in a bucket of sand.

That being said, I'm going to weld (remember, we're dealing with forged steel here) some additional reinforcement to the arm this afternoon before re-assembly to provide an additional level of insurance. Do I think I need it? No. Am I going to do it anyway? Yes.

Any arm I buy wouldn't be what I need so regardless of what the "correct" path forward is, I'd end up heating and bending whatever showed up. This arm is time tested and proven crack free this far. Anything else that would arrive in the mail (used for sure, new possibly) would be a questionable start.....

SG