So the big adventure to Nova Scotia was an eye opener in a number of ways. From a family and travel standpoint I think we have fallen in love with Boomer even more. The size of the rig is ideal for a family of 4 who wants to be able to really explore. I didn't feel limited by our size at all for the kind of excursions we wanted to participate in. I'm not a "4-wheeler" and Boomer wouldn't be able to wind its way through a dense forest trail, but off-highway adventures are par for the course and we are sprouting with ideas for "where next". Alternatively, I'm not sure I would go with a rig much bigger. Would I like more interior space? Of course I would, but the limitations both in height as well as turning radius, overhangs, breakover angle, and overall length would really limit our ability to go where we want to go. We are going to address some living space annoyances in the coming months.

From a gear standpoint, Boomer did very well. All of the modifications performed flawlessly. The new steering and suspension setup was magnificent and really made the driving a pleasure. No bumpsteer, control over all sorts of different road conditions. A pleasure.

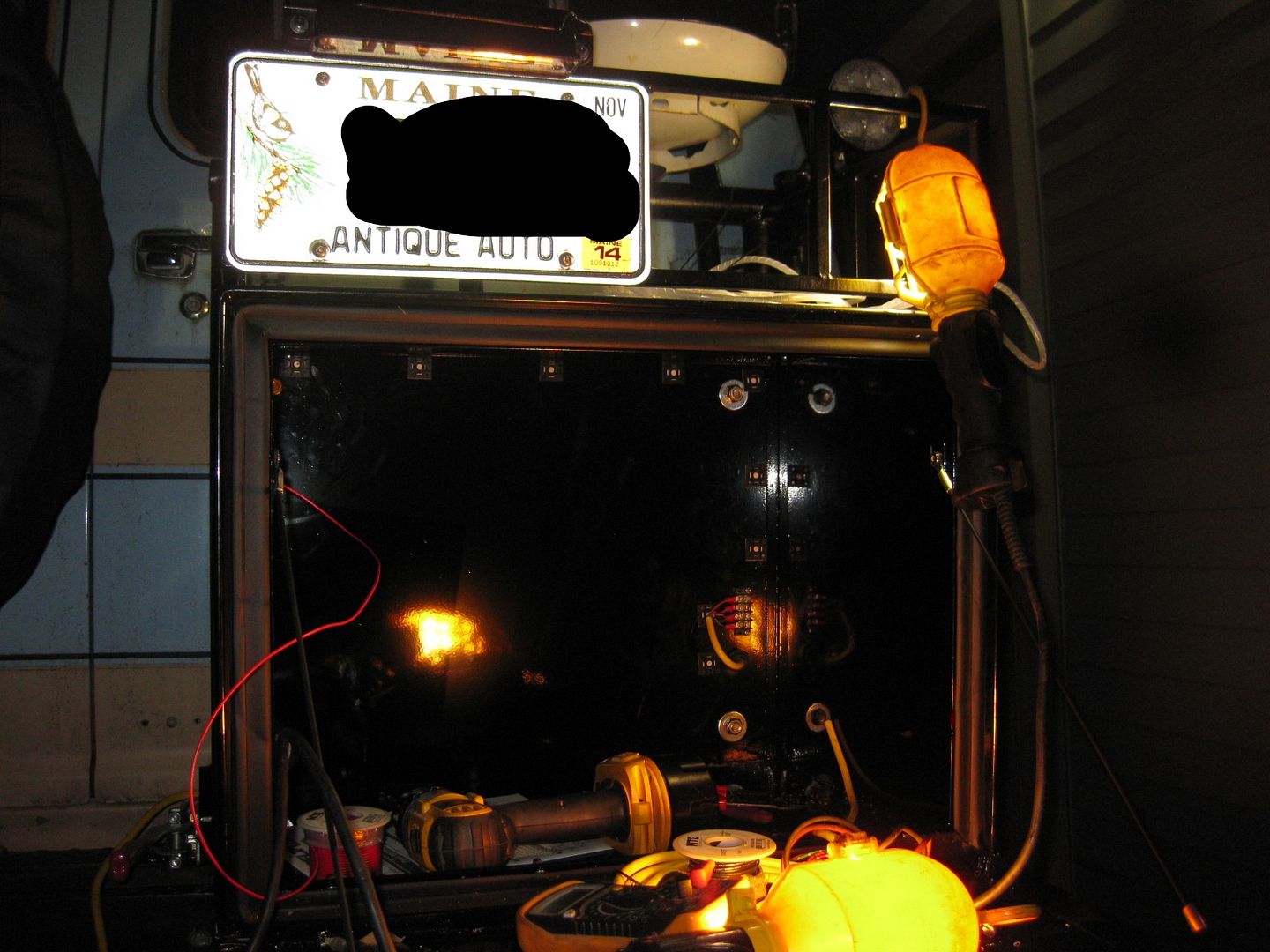

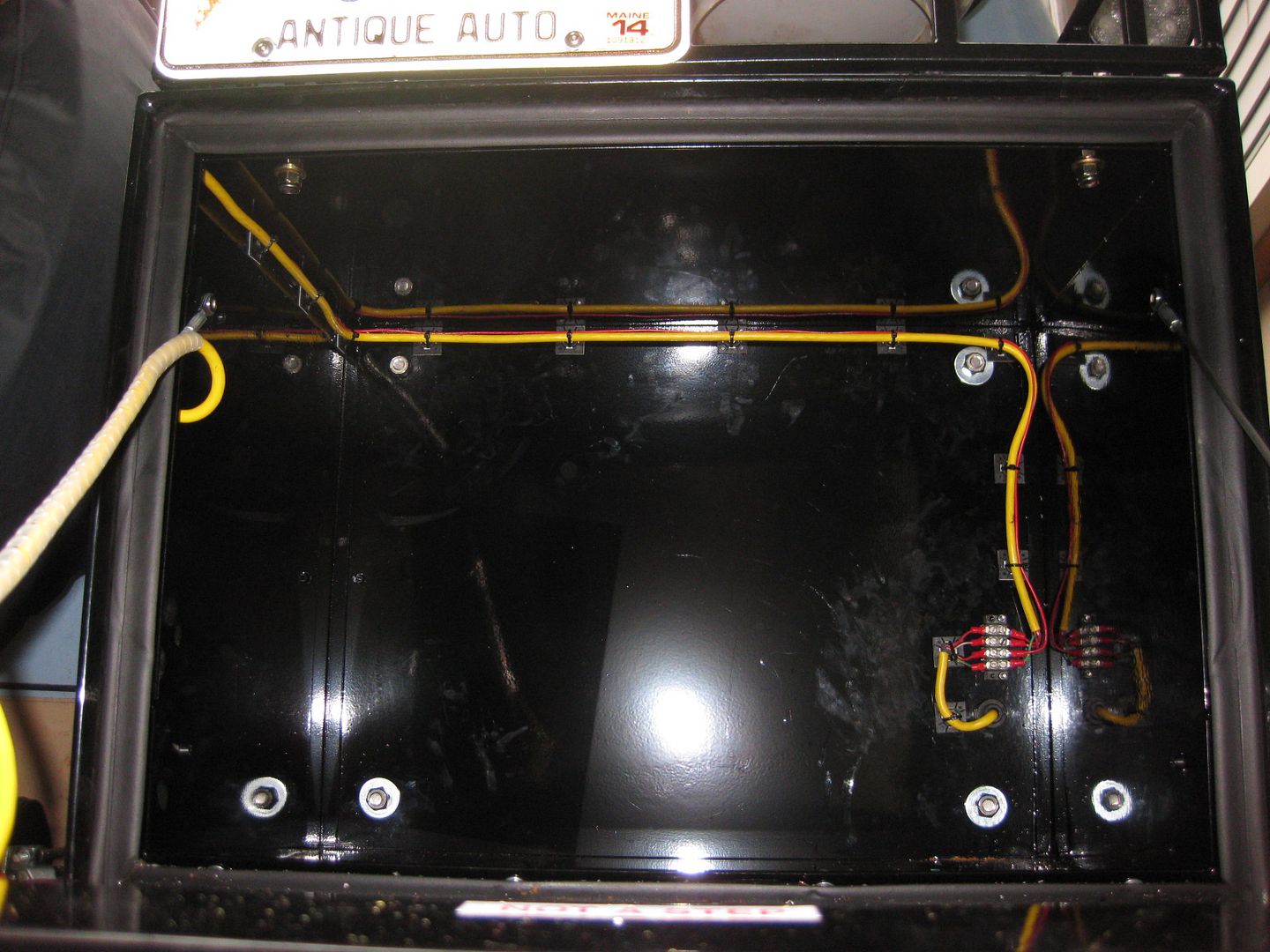

The swing outs didn't fall off. What more can I say? The rear box was superb for isolating the grimier stuff which one must carry on an adventure like this from daily life. It was easy to access and quick to get out of the way. Additionally, the box basket was a great place to throw stuff (like my stinky flip-flops which were forbidden from the van on day 2).

The convenience of the propane bottle being mounted and connected 100% of the time can't be overstated. We shut the valve off each morning before departure, but at camp the first thing I did was pop open the propane so the stove could be used whenever necessary. We did have an issue with the quick disconnect fitting leaking like crazy, but after we returned I realized it was my own fault, as I had ordered a low pressure disconnect rated to only 0.5 PSIG. On the road, I removed the quick disconnect entirely and capped it. We used a disposable propane bottle for the grille from that point on which ended up being a good thing since we were low on propane in the primary bottle anyway.

In the trip report many of you will notice some stuff lashed to the roof. To give us as much space inside as possible for storage of bags and sleeping gear, I opted to throw the camp chairs, camp table, and our Kelty kid carrier up on the roof. Given the rain we endured, everything was placed in contractor garbage bags first with the bags being lashed with bungee cords. The 3 "packages" were then lashed to the roof with a pair of ratchet straps fastened to the questionable roof rail. The whole setup lasted the trip but the bags were useless after day 3. Full of holes. We recognized the value of good waterproof roof storage and will improve upon our "system" next year.

Another exterior item which we both love and feel the need to improve upon is our awning. The old Fiamma unit is tired, and the canvas is badly stretched. The framework and reeling mechanism are in good shape, but I see an upgrade in the near future. The current awning is a 10ft unit with a coverage distance of 7 ft. During inclement weather it is so nice to still keep the doors open and be able to "live" under the awning. Fiamma has an nice F45 line which would allow us to go up to 13' of length which I can just barely squeeze in, and it would have almost 9ft of coverage. In addition, Fiamma sells sidewall kits for their newest models which would literally double our living space. This upgrade will happen within the next year.

Interior storage solutions are tricky for all of us. Before the trip my wife was concerned about where food would be stored as well as all the stuff to keep the kids entertained. There was no time for me to get creative, or really for me to do ANYTHING about it. She being she, initiative is never a problem. A quick trip to the store and my wife had three decent sized stackable totes. Behind the second row driver seat there is a space for 2 of these totes to be stacked and still allow plenty of isle space for passage as well as opening the refrigerator door. She loaded the tote at the floor level with heavy items, and the tote stacked on that with light items. Between the back of the driver seat and the front of the second row seat, she was able to squeeze the 3rd tote. With the kids being small, the need for a footwell is something we can "worry about later". The rest of the daily life items were able to be stored in the more traditional cubby locations around Boomer. This solution ended up being great until the contents of the totes began to be consumed. Only after they started to lighten up did we get a few instances of toppling when rounding a bumpy sharp corner.

Communication ended up being a bit of a challenge on this trip. We couldn't use our phones in Canada (at least, we thought we couldn't), and getting a SIM card that isn't tied to local calls only while at the same time not requiring a contract of some sort proved nearly impossible. When you read on the web, so many people talk about just getting a local SIM card when traveling internationally. A couple things about this. #1 is that the handset you bring along MUST BE UNLOCKED!!!! We brought an AT&T GSM handset and it was worth its weight in bat guano. Further, to use the handset with a Canada-wide SIM card would have required a credit check, setting up a plan, and so on. This was way more of a hassle then I was prepared to go through so we ended up dropping the idea of a cell phone entirely. Upon my return I discovered that for a nominal fee (certainly less than buying a burner phone with only a local calling radius) I could have added an international feature to the plans on one of our phones which would have allowed calling and light data use. We would do this next time. Something to consider about cell phones is that they probably won't work in rural areas anyway. We have a CB on board as well as a few TalkAbout handsets for trail and campsite communication. I think I finally acknowledge the value of a HAM radio and I will be acquiring one (along with the technician license) this year. The ability to reach out when you're in trouble is paramount, especially when traveling with a young family. There were a couple instances where I felt overly vulnerable not having a way to get roadside help and I want to avoid this as much as possible in the future.

While on the topic of electronics, the ability to get a WiFi signal ended up being a challenge. Boomer's all-steel construction acted as a magnificent WiFi signal shield. The CF-19 Toughbook with its internal WiFi card was nearly useless unless we were within maybe 75 ft of the WiFi source. My wife's MacBook did far better, but she was still limited to around 150ft from the WiFi source. Since an internet connection on the road isn't going to be "convenient" most of the time, I want to do something about our ability to get a signal from a far-off router.

Lastly, the drivetrain. Boomer is equipped with an antiquated International 6.9L indirect injection normally aspirated (non-turbo) diesel and a C6 3 speed non-lockup automatic transmission. We had issues with both of these pieces of equipment during the trip.

The transmission was overfilled when we started off which is clearly "operator error". However, even after correcting this condition on the road I still had transmission temperature concerns. A few years back when towing a trailer home, Boomer's transmission overheated. I didn't have a transmission cooler installed at the time so while on the road I installed the largest fin tube model I could find locally which happened to be an 18k GVW capacity unit. I haven't ever had a temperature gauge for the transmission, so for this trip I finally installed one. You know what they say about gauges....if you have one it just gives you something else to worry about. Below 45 MPH, the temp (exit fluid temp entering the cooler circuit) holds around 180-190 which I consider acceptable. At level highway speeds of 60-65 MPH, the transmission hovers around 200-210. At highway speed going up any sort of grade we're immediately up in the 220-230 deg range. I never saw the transmission get over 235, but I still don't like running that hot. This needs to be addressed ASAP.

The engine on the other hand stayed cool the whole trip which, given all the other stuff going on, was not lost on me. I appreciated not having to worry about that on top of all the other things. The engine however was not without its own problems. After a series of very rough pavement in New Brunswick I started getting a lot of strange surging while underway. After lots of false diagnosis, the culprit ended up being a faulty stock (and original to the truck) water/fuel separator. I temporarily fixed the issue (on the last day, of course) by short circuiting the separator with a length of fuel hose. Running without this device for any amount of time isn't an option, so a replacement needs to be found and installed. Preferably something more industrial with a better reputation than the one which has failed me. While I'm at it, the fuel gauge for the forward tank isn't working, and neither gauge has ever read the correct fuel level. I also don't believe the pickups in the tanks are in good shape as I'm not able to draw 100% of the fuel from the tanks before I start sucking air (both tanks leave around 2 gallons behind). So I need to drop the tanks, fix the level sensors and either fix or modify the pickups so I can utilize 100% of my fuel capacity.

SG