Get your tickets to THE BIG THING 2026!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Boomer the Quadravan 4x4 Camper

- Thread starter spencyg

- Start date

Mwilliamshs

Explorer

you're right on with the louver idea. that big mamba diesel makes some heat. i've never looked for space to fit a pusher fan between the grille and radiator but one of these wired to come on with A/C (to get a jump on things before they heat up) and also on a temp switch (in case you get warm underhood without the A/C running) and a manual override (cuz I'm a control freak) would be the cat's pajamas.

Some critical new bits and pieces started arriving at the end of last week.

-Parker Water/Fuel Separator

-22k GVW FTR transmission cooler

-Hella Supertone Horn Set

-9x5 Stainless Steel Hood Louvers

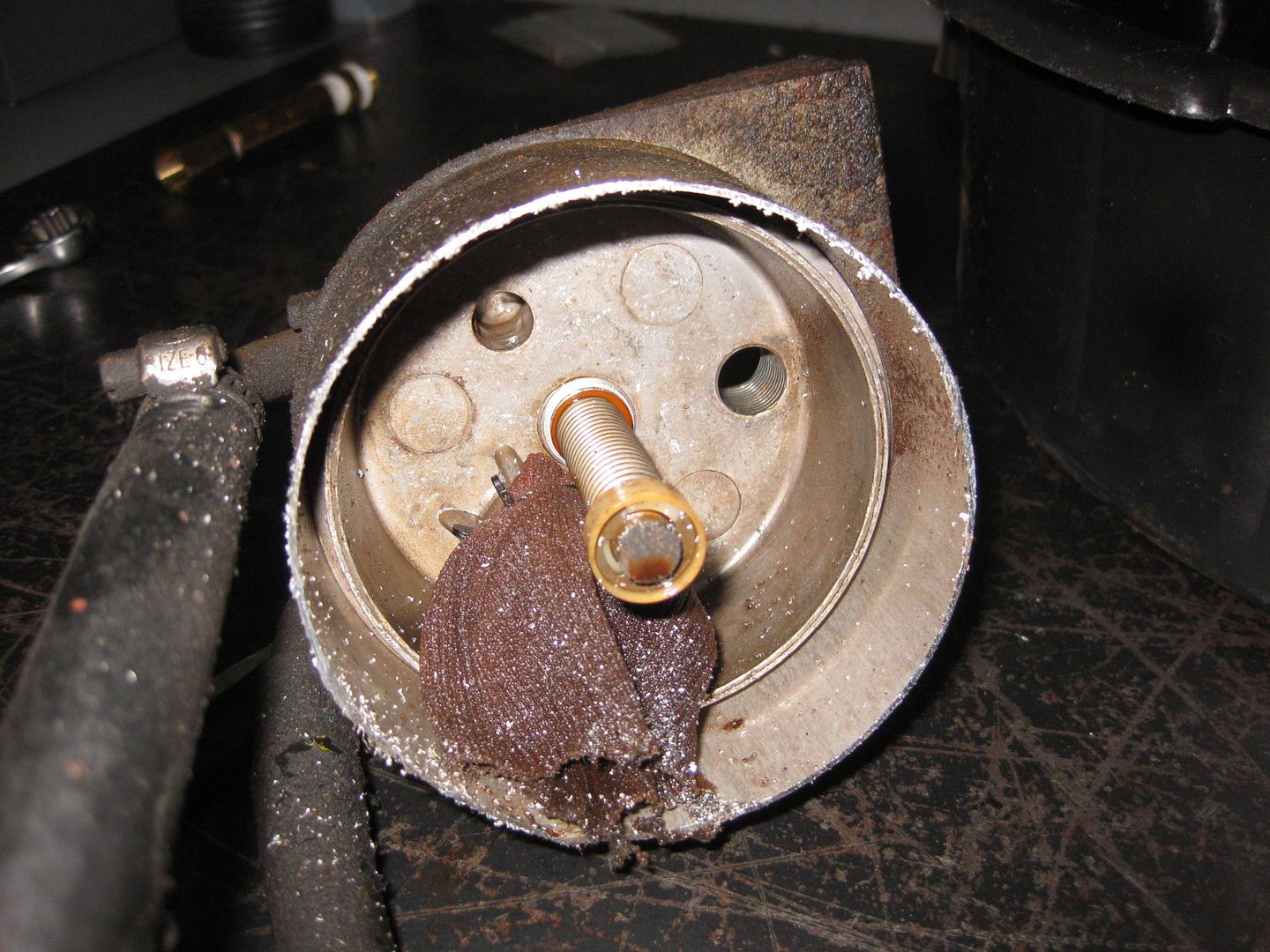

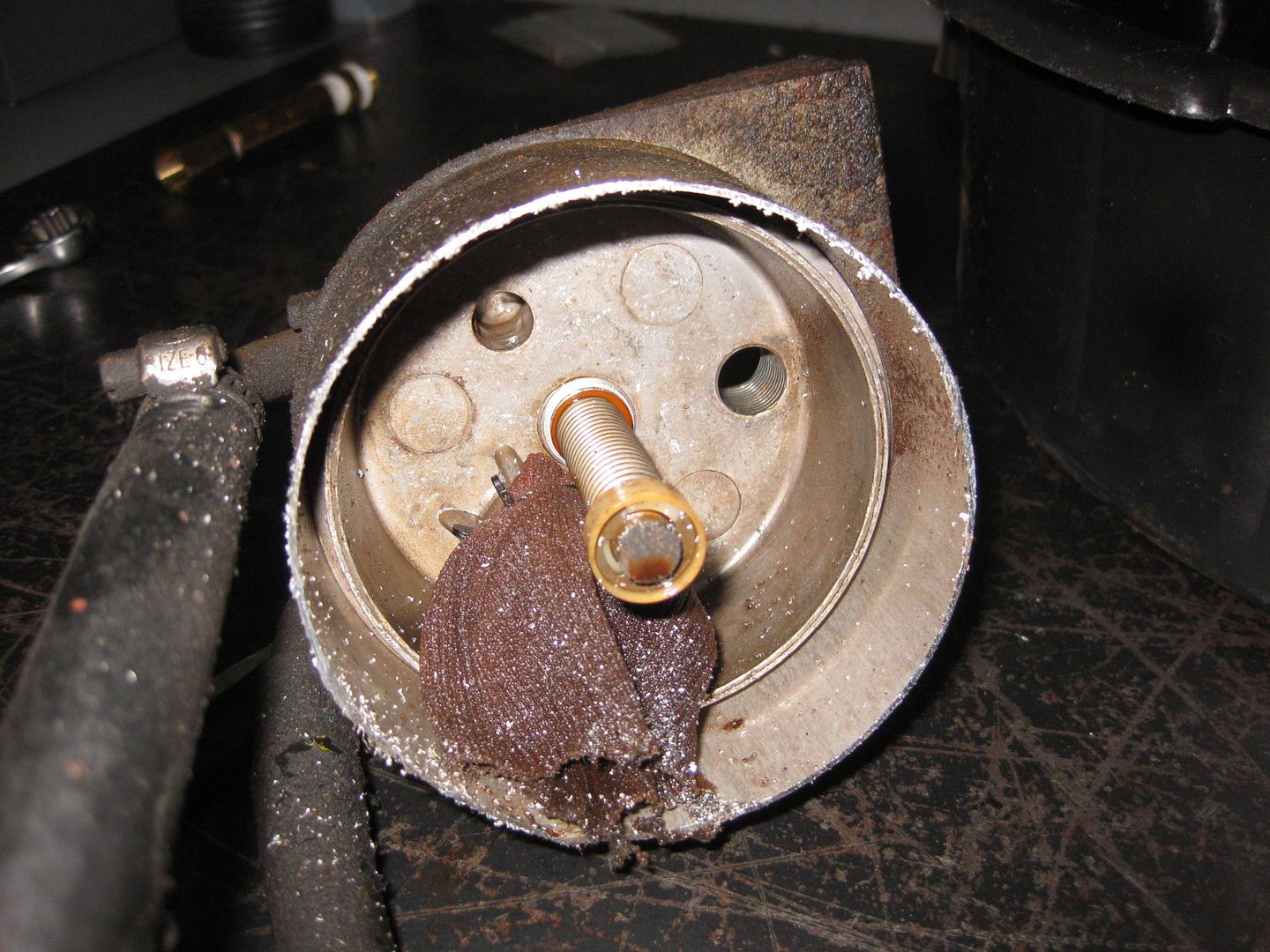

First chore is to fix the water fuel separator issue. The offending hardware...

The assembly came out easily enough. The bracket bolted to the frame through the face of the frame rail...very strange setup.

This was the first chance I've had to see this piece of hardware that has such a poor reputation from other IDI owners. At first glance the thing looks reasonable enough. Only when you try to take it apart and realize it is non-serviceable that the true nature starts coming to the light. So of course, for science I had to open it up.

Oh dear. Dear oh dear.

Sludge, so much sludge. It is no wonder this thing wasn't working.

When I pulled the assembly down I found the water sensor was unplugged. When I dumped the cup it had a bunch of water in it (and sludge...). What I find especially interesting is that the "filter" is on the "out" circuit. All that sludge just sits in the bowl and can't be cleaned or flushed. The filter (read: old sock) keeps the crap out of the injection circuit until it is so clogged it can no longer pass fuel. I noticed at least 2x the flow out of the primary filter purge valve when I short circuited the fuel/water separator and now I know why.

So I've started fabricating a new bracket for the Parker...

no pics yet....by starting I mean "I've got to get started".

SG

-Parker Water/Fuel Separator

-22k GVW FTR transmission cooler

-Hella Supertone Horn Set

-9x5 Stainless Steel Hood Louvers

First chore is to fix the water fuel separator issue. The offending hardware...

The assembly came out easily enough. The bracket bolted to the frame through the face of the frame rail...very strange setup.

This was the first chance I've had to see this piece of hardware that has such a poor reputation from other IDI owners. At first glance the thing looks reasonable enough. Only when you try to take it apart and realize it is non-serviceable that the true nature starts coming to the light. So of course, for science I had to open it up.

Oh dear. Dear oh dear.

Sludge, so much sludge. It is no wonder this thing wasn't working.

When I pulled the assembly down I found the water sensor was unplugged. When I dumped the cup it had a bunch of water in it (and sludge...). What I find especially interesting is that the "filter" is on the "out" circuit. All that sludge just sits in the bowl and can't be cleaned or flushed. The filter (read: old sock) keeps the crap out of the injection circuit until it is so clogged it can no longer pass fuel. I noticed at least 2x the flow out of the primary filter purge valve when I short circuited the fuel/water separator and now I know why.

So I've started fabricating a new bracket for the Parker...

no pics yet....by starting I mean "I've got to get started".

SG

I found a little time yesterday and today for some quality time with the old van.

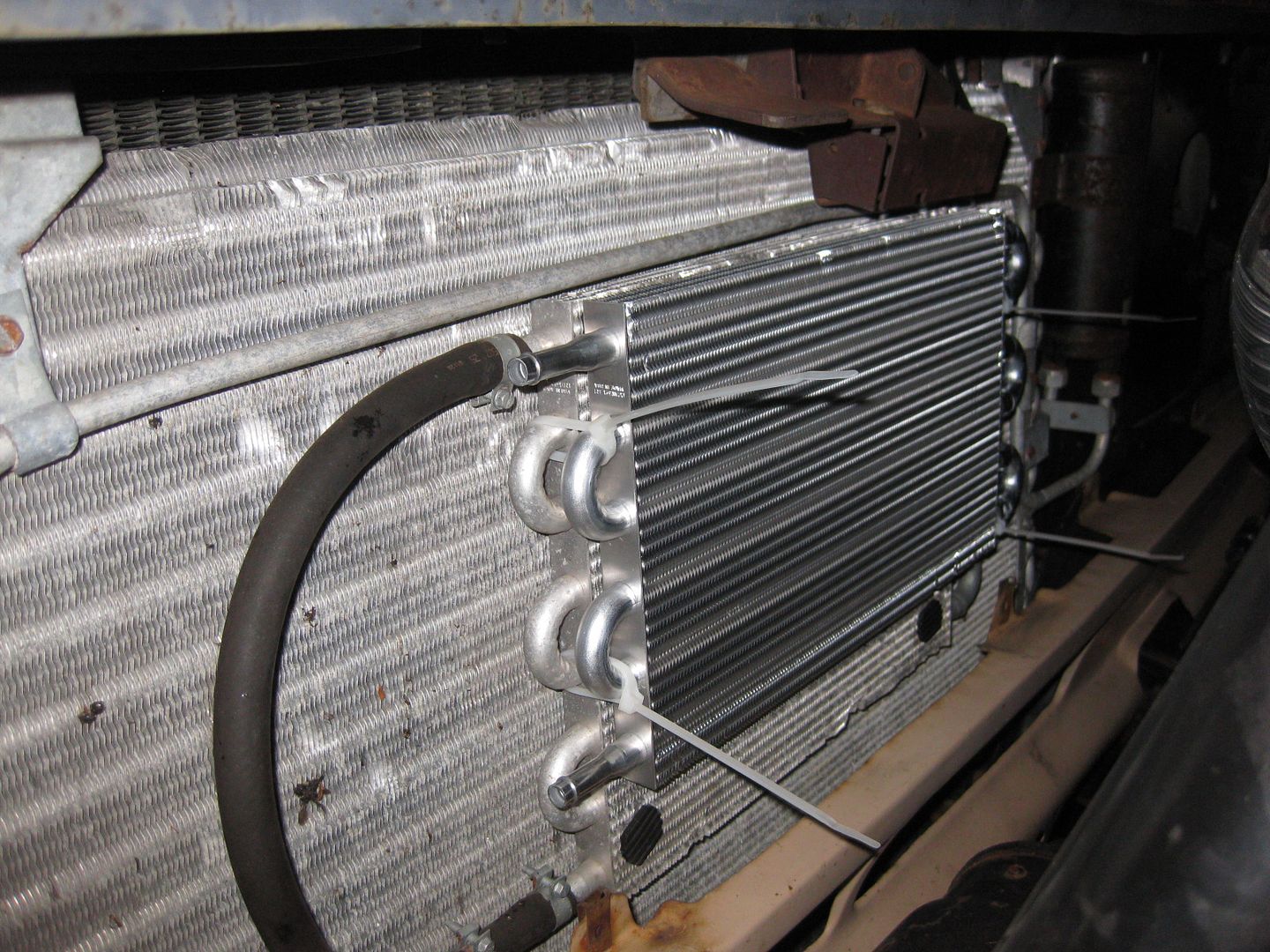

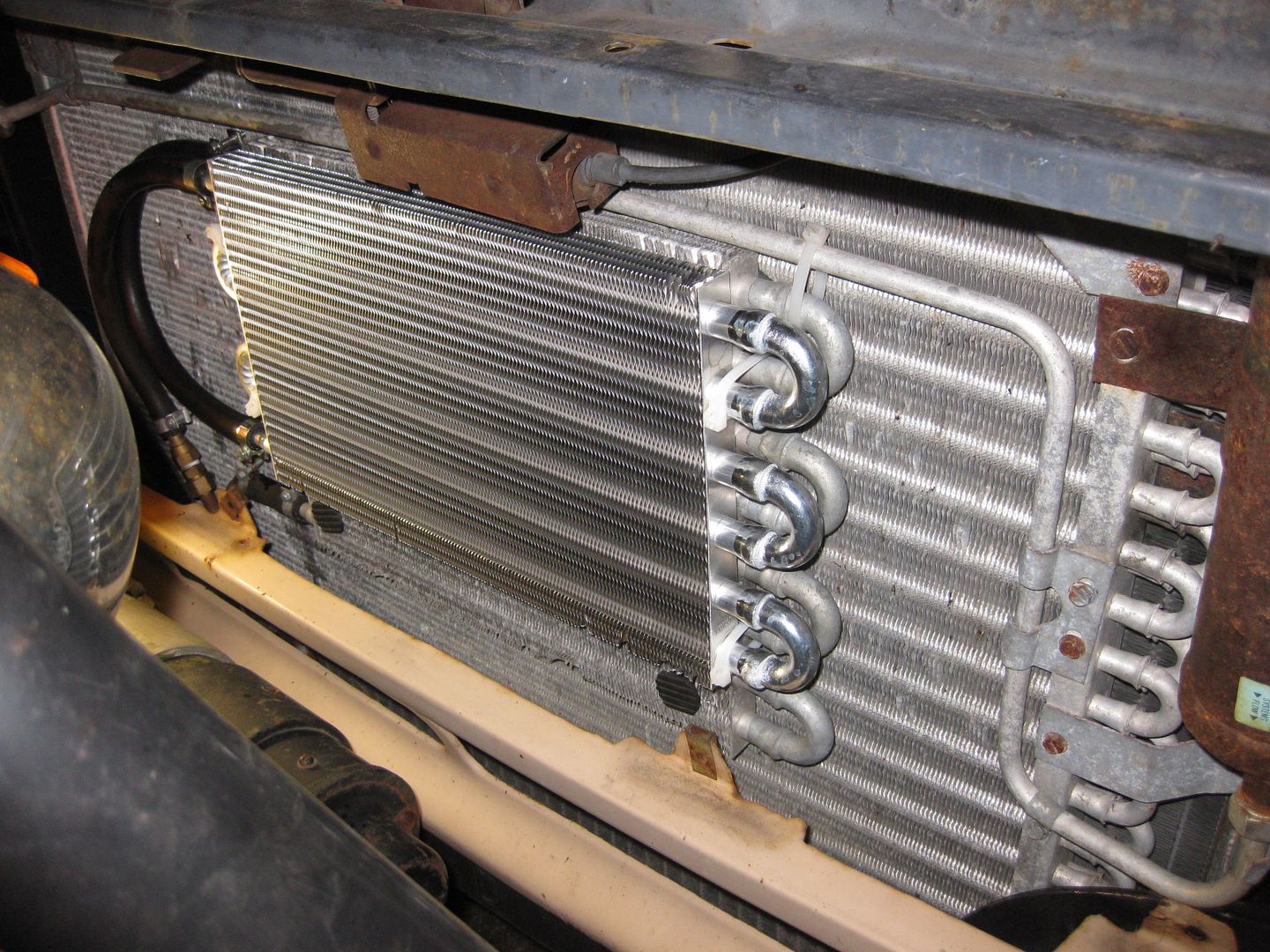

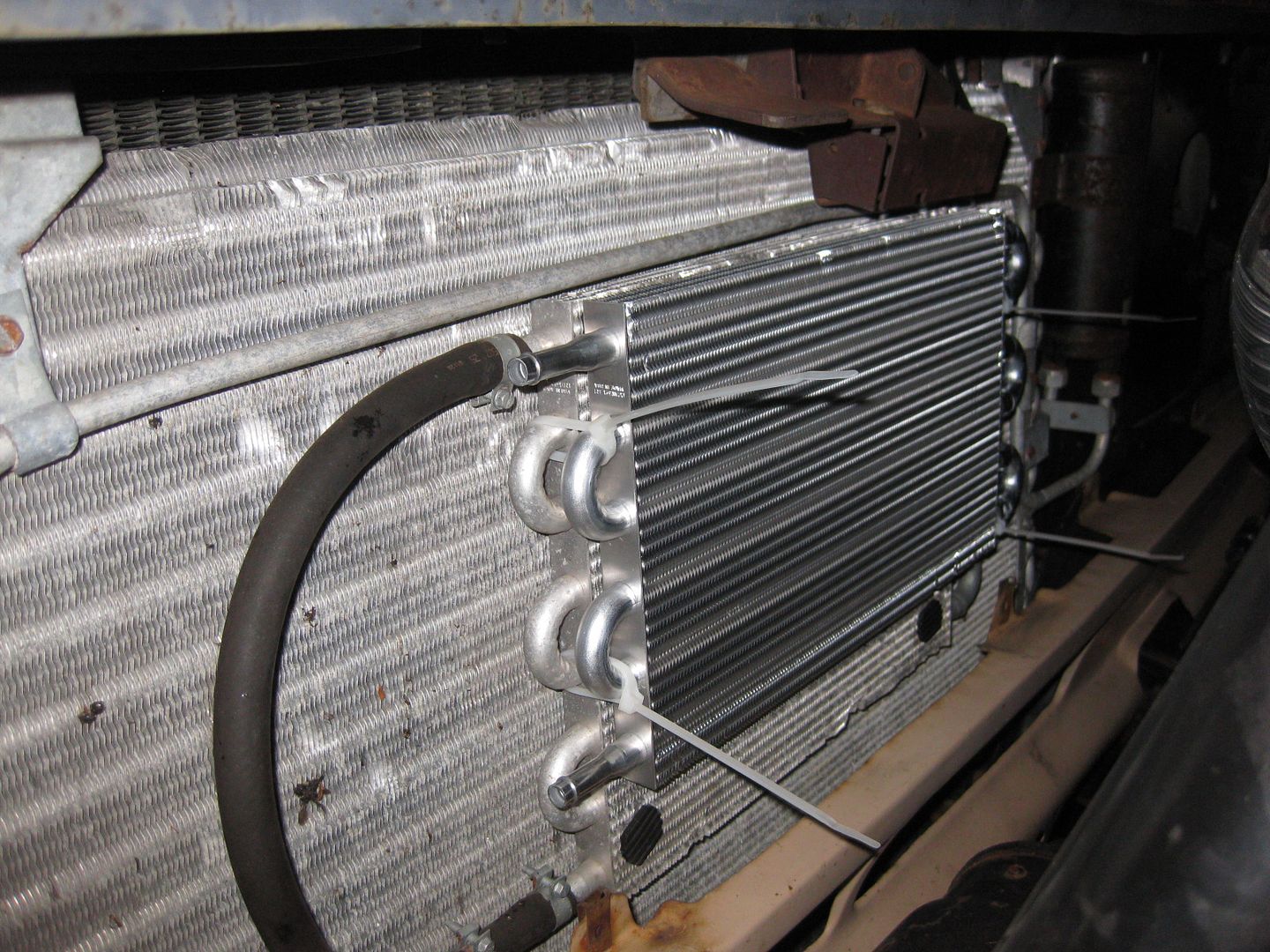

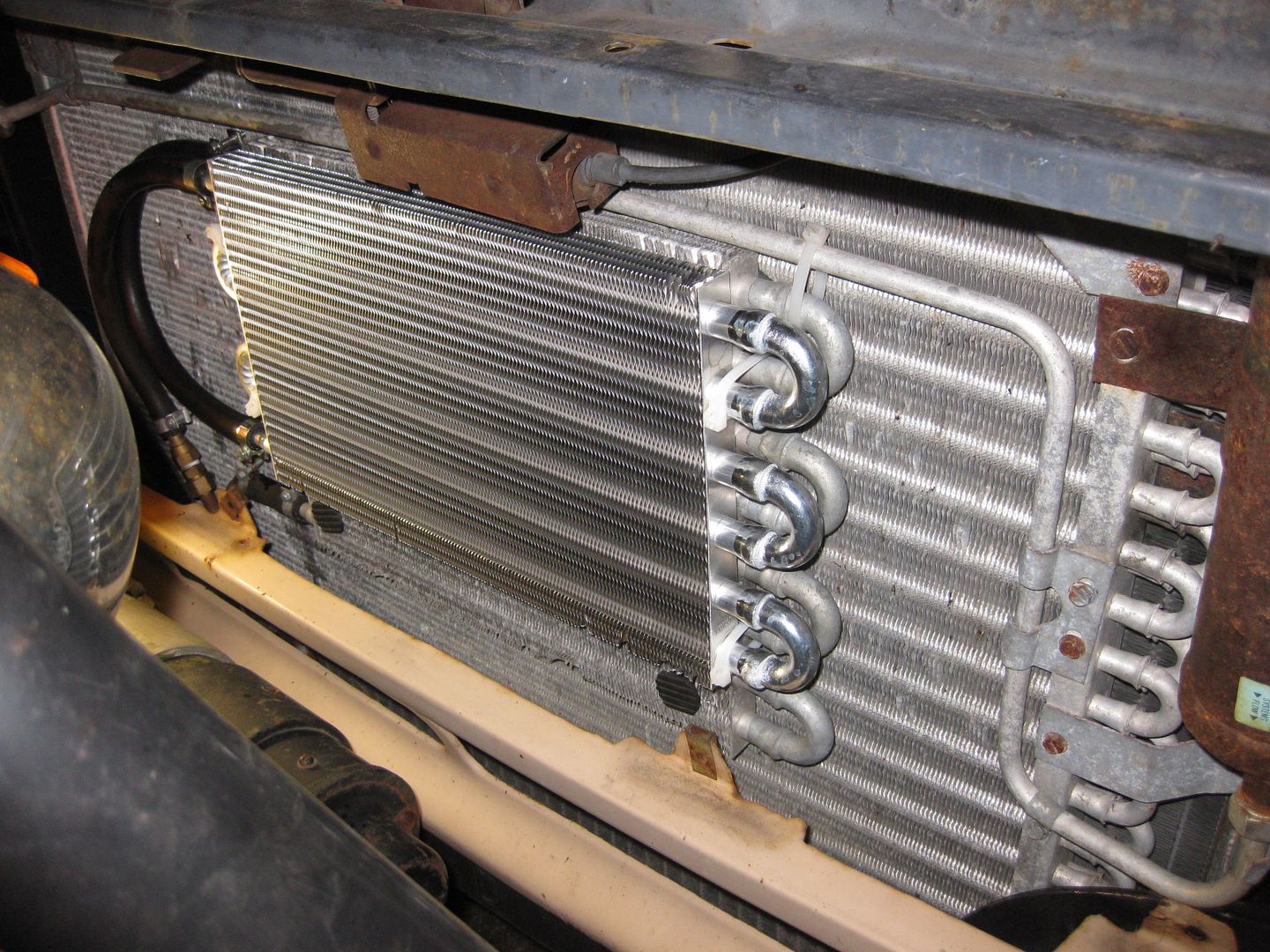

I started in on the new transmission cooler. The one I had installed before...

Being how much attention I pay to the fine details, I quickly discovered that the one I already have installed was LARGER than the new one in the box.

Super smart. That's me.

So what does one do when you've got a new transmission cooler, ordered specifically to be larger than the one you've got, only to find it isn't at all larger but actually 20% smaller.

You make a sandwich. That's what.

So now I've got a dual core transmission cooler that I can re-circuit if need-be down the road should one of the units fail. I actually feel pretty good about this.

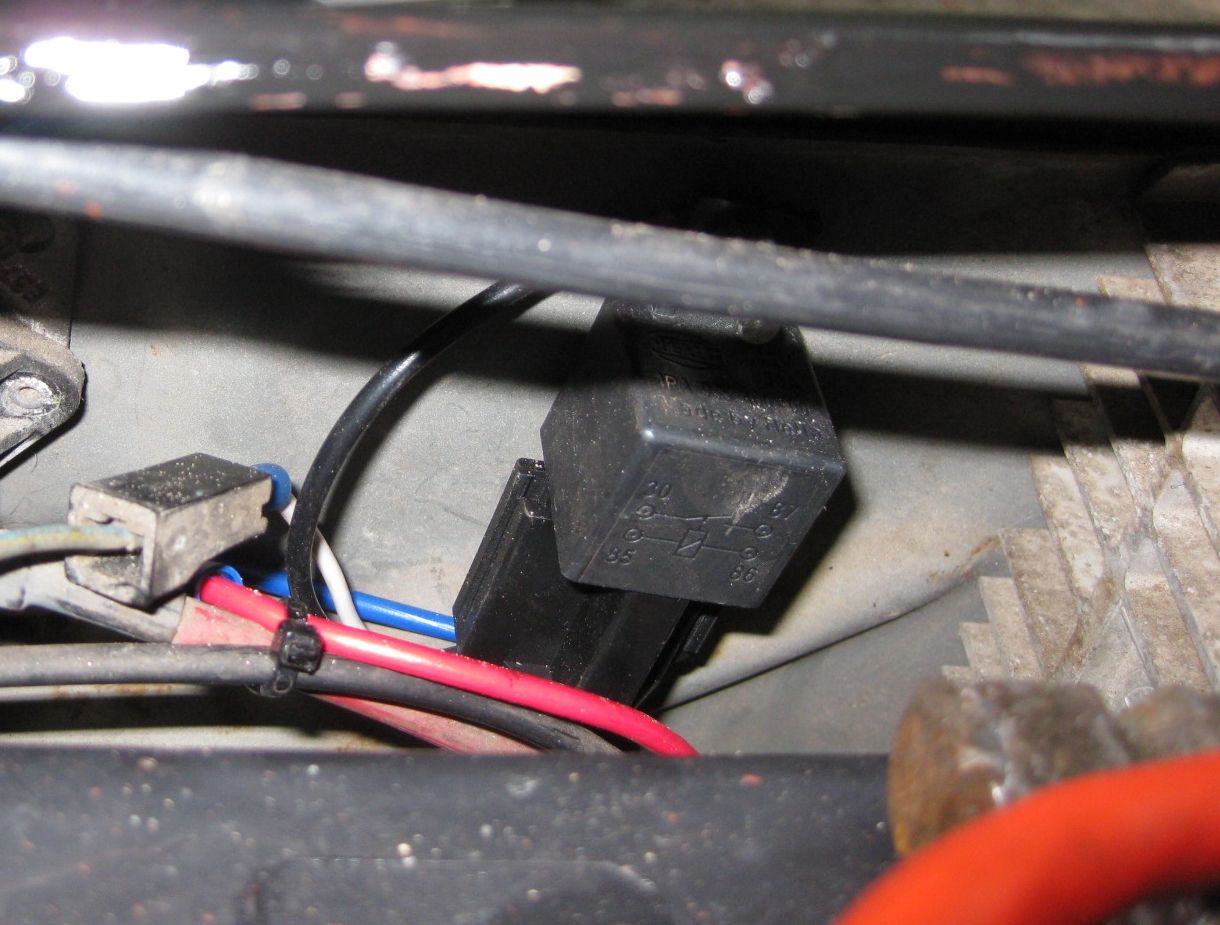

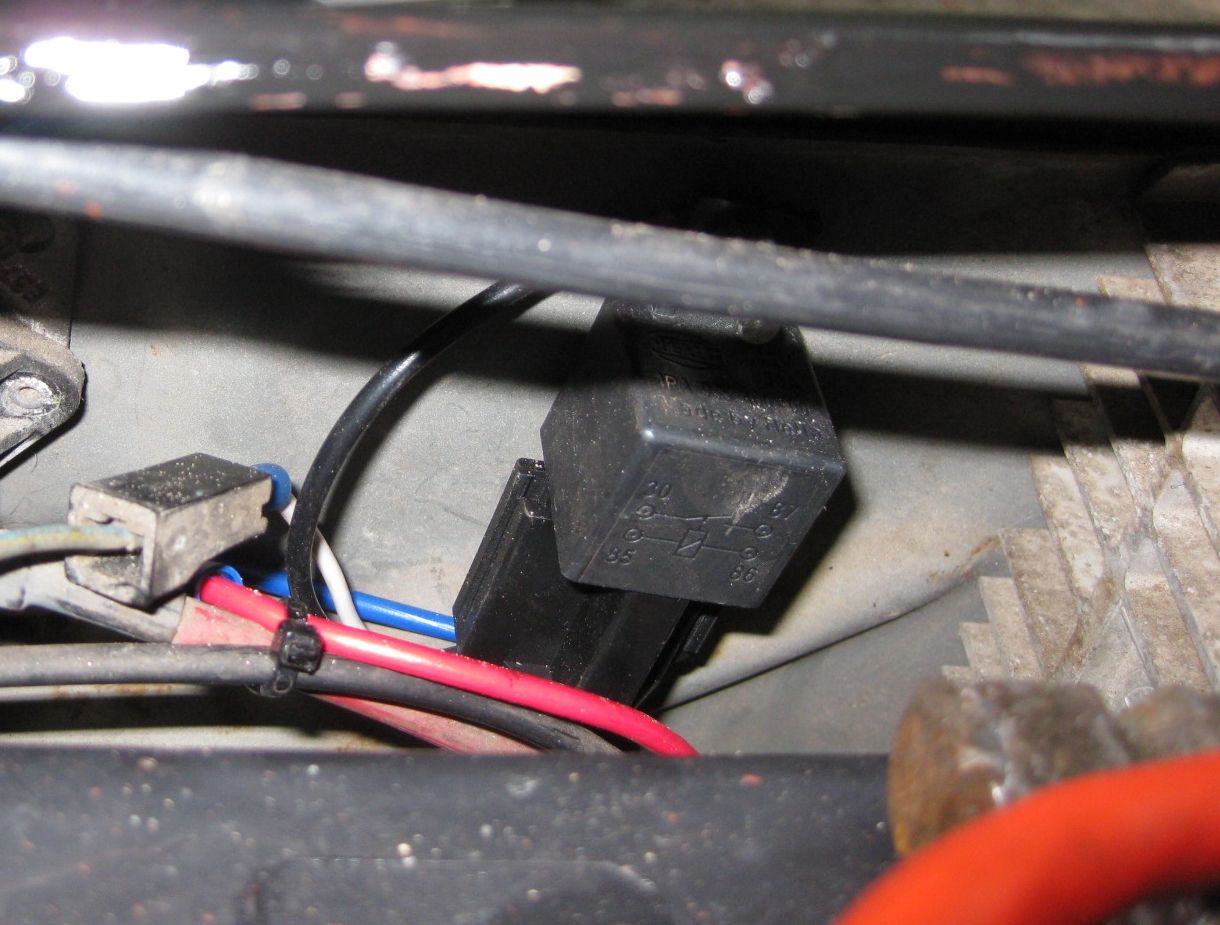

Moving right along, I opened up the new Hella horn box and found that they draw enough current to warrant a power relay. So instead of just installing a pair of horns, we needed to wire up a relay first.

Have you seen how much room there is under the hood of a 1986 Econoline lately?

The horns themselves won't fit behind the grille so I routed the power wire down to the bumper.

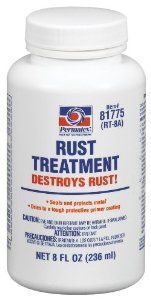

Before buttoning up the grille I did some rust prevention and repair work on the upper radiator support.

Napa Rust Treatment to the rescue. I know I've touted this stuff before but I'll look for any opportunity to bring it back up....

Boomer maintains a "healthy" amount of corrosion as a result of this stuff. It doesn't do a thing on clean steel or paint...in fact, it flakes right off. Throw it on rust however and the stuff turns black as coal and hardens into a very tough base. I typically put a coat of rust treatment on the bad areas, then a coat of rustoleum "rusty metal" primer followed by my color choice of professional grade rustoleum enamel. All coats are brushed on....my expedition vehicle doesn't attempt to be something it isn't, and it isn't pretty.

Me being me, I did the black coat right before a thunder storm and closed the hood to protect the paint. Later in the evening I inspected the paint and found the insulation (which I'll be ripping out shortly) had stuck to the paint. So tomorrow I'll need to sand and recoat. Idiot.

Then on to the new Racor fuel/water separator. I finished up the new bracket and painted yesterday.

Installation went fine. I needed to add a 90 degree bend to get the hose routing correct, but in the end it was fine.

Getting everything purged went as expected...lots of engine cranking. Looks like the fix will hold and our fuel aeration issues are over for now.

While I was crawling around in the dirt I purged another 2 quarts out of the transmission circuit to get the level down to normal. Finally I'm reading at "full" when the transmission is warm instead of "full+a bit".

And since I was now dirty and covered in oil, I decided to pull the drain plug on the transfer case. I had never actually looked in there before so I wasn't sure what to expect. Pre-research on the topic led me to believe the transmission would filled with either ATF or gear oil. The stuff that drained out was more like maybe 30 weight motor oil (??). Anyway...all drained and I went to the store to get refill fluid for tomorrow along with a vent for the rear swing-out box.

Strangely, the rear box has been VERY humid. It is totally sealed so all I have been able to figure is that the water hose and blackwater drain hose are bringing water into the box, and once its closed the water evaporates with the heat (sun on box) and then condenses at night. The water I'm finding is clinging to the ceiling and upper walls of the box. Very strange.

So I'm going to add a vent to get the box a little dryer. We'll see how that goes.

SG

I started in on the new transmission cooler. The one I had installed before...

Being how much attention I pay to the fine details, I quickly discovered that the one I already have installed was LARGER than the new one in the box.

Super smart. That's me.

So what does one do when you've got a new transmission cooler, ordered specifically to be larger than the one you've got, only to find it isn't at all larger but actually 20% smaller.

You make a sandwich. That's what.

So now I've got a dual core transmission cooler that I can re-circuit if need-be down the road should one of the units fail. I actually feel pretty good about this.

Moving right along, I opened up the new Hella horn box and found that they draw enough current to warrant a power relay. So instead of just installing a pair of horns, we needed to wire up a relay first.

Have you seen how much room there is under the hood of a 1986 Econoline lately?

The horns themselves won't fit behind the grille so I routed the power wire down to the bumper.

Before buttoning up the grille I did some rust prevention and repair work on the upper radiator support.

Napa Rust Treatment to the rescue. I know I've touted this stuff before but I'll look for any opportunity to bring it back up....

Boomer maintains a "healthy" amount of corrosion as a result of this stuff. It doesn't do a thing on clean steel or paint...in fact, it flakes right off. Throw it on rust however and the stuff turns black as coal and hardens into a very tough base. I typically put a coat of rust treatment on the bad areas, then a coat of rustoleum "rusty metal" primer followed by my color choice of professional grade rustoleum enamel. All coats are brushed on....my expedition vehicle doesn't attempt to be something it isn't, and it isn't pretty.

Me being me, I did the black coat right before a thunder storm and closed the hood to protect the paint. Later in the evening I inspected the paint and found the insulation (which I'll be ripping out shortly) had stuck to the paint. So tomorrow I'll need to sand and recoat. Idiot.

Then on to the new Racor fuel/water separator. I finished up the new bracket and painted yesterday.

Installation went fine. I needed to add a 90 degree bend to get the hose routing correct, but in the end it was fine.

Getting everything purged went as expected...lots of engine cranking. Looks like the fix will hold and our fuel aeration issues are over for now.

While I was crawling around in the dirt I purged another 2 quarts out of the transmission circuit to get the level down to normal. Finally I'm reading at "full" when the transmission is warm instead of "full+a bit".

And since I was now dirty and covered in oil, I decided to pull the drain plug on the transfer case. I had never actually looked in there before so I wasn't sure what to expect. Pre-research on the topic led me to believe the transmission would filled with either ATF or gear oil. The stuff that drained out was more like maybe 30 weight motor oil (??). Anyway...all drained and I went to the store to get refill fluid for tomorrow along with a vent for the rear swing-out box.

Strangely, the rear box has been VERY humid. It is totally sealed so all I have been able to figure is that the water hose and blackwater drain hose are bringing water into the box, and once its closed the water evaporates with the heat (sun on box) and then condenses at night. The water I'm finding is clinging to the ceiling and upper walls of the box. Very strange.

So I'm going to add a vent to get the box a little dryer. We'll see how that goes.

SG

I was able to get the horns mounted today. I ended up finding a couple spots behind the grille which ended up being a far better solution than trying to get them into the bumper.

Did I mention that these new horns are LLLLLLOOOOOUUUUUUDDDDDD!!!! I actually wired them in parallel with the stock horn, so I've got all 3 blaring at the moment. Sweet.

I was also able to get the paint repaired on the radiator support and filled the transfer case with 75W-90 GT5 gear oil.

SG

Did I mention that these new horns are LLLLLLOOOOOUUUUUUDDDDDD!!!! I actually wired them in parallel with the stock horn, so I've got all 3 blaring at the moment. Sweet.

I was also able to get the paint repaired on the radiator support and filled the transfer case with 75W-90 GT5 gear oil.

SG

Interesting bdog. I hadn't considered the possibility that the stock radiator circuit may be compromised. I did take Boomer into work this morning in 50 degree temps and now I seem to be overcooling the transmission. I only have maybe 3 miles on interstate roads but the transmission never got over 150 degrees and spent most of its time around 140. This is a little cooler than it should be. Instead of removing the cooler I just put in (because when I'm loaded and its 90 degrees outside I want as much cooler as possible) I'm considering a Hayden 163 Oil Thermostat. It has 2 ports in and 2 ports out. I can short circuit my secondary coolers entirely and run with just the radiator cooler when the temps are cold, and when things warm up the secondary coolers will come online. The 163 begins opening at 160F and is fully open at 180F. I'll check the radiator circuit as well to ensure that is clean and freely flowing.

SG

SG

As I mentioned in a previous post, the rear box has been plagued with condensation which has caused everything to stay wet. The canvas bag I keep all the recovery gear in is pretty "gamey" with all that moisture and it isn't really good for anything I'm keeping back there. I just installed the vent last night in hopes that a vent in the box will make these issues go away.

I sandwiched some bug screen between the box and the louver so hopefully allow only air to pass in and out. I hope this works.

SG

I sandwiched some bug screen between the box and the louver so hopefully allow only air to pass in and out. I hope this works.

SG

Mwilliamshs

Explorer

Could use a desiccant like Damprid, etc.

If it comes down to it I'll have to, but I refuse to believe I can't have a reasonably dry locker on the back bumper without the need for chemical drying measures. We might be heading into the mountains this weekend for some camping so hopefully I'll get a better sense of things then.

SG

SG

Ever use por-15. The permetex sounds similar. Sounds like you need to get all paint off? I need to do some work on door bottoms but some paint still there.

On condensation issue makes me think of the rod heaters used in gun safes. Goldenrod... Not seeings sure if there is a 12/24v version. Hope the vent works.

On condensation issue makes me think of the rod heaters used in gun safes. Goldenrod... Not seeings sure if there is a 12/24v version. Hope the vent works.

I have used POR15 once before and I found the outcome to be similar. I found POR to be more of a "1 and done" solution where the Permatex Rust Converter is just part of a 3 step process. I think with both POR15 and certainly with Permatex, you need the surface to be down to wire brushed metal/dusty rust. Any flakes remaining before applying the converter would potentially mask off areas you want the converter to contact. I have found with personal experience that the converter will flake off of any paint once dry, so it actually compromises paint adhesion when used anywhere other than rusty steel.

SG

SG

Boomer got out for a little weekend trip out toward the western part of the state. The little adventure was a last minute thing which is always fun and helped to identify a couple additional issues. Toward the end of the NS trip we started having issues with the water pump "bumping" (shurflo 2088) when no water was being used. In the past this has indicated a leak in the system, but after pulling the fridge and couch cushions I couldn't find any signs of leaks. The problem seemed to go away and I didn't give it another thought until this past weekend when it started happening again. When we returned I removed the water pump and found the integral check valve was a little sticky. While I had it apart, I removed a nylon "T" fitting which was installed directly after the pump to allow the use of "city water" instead of the onboard tankage. The fitting was bent, and after wiggling it around to remove the pump it actually broke. Last night I replaced the plastic fitting with a brass one and buttoned the system back up. No more bumping water pump!

The weather this past weekend was a little on the cold side which gave us the opportunity to use the cabin heater. Strangely, I had a couple instances of the unit not lighting which was a new problem. The heater is ignited with a little transformer and a couple probes. I removed the probes, cleaned them up with 600g sandpaper and reinstalled. Everything seems to be working again but I'll be keeping my eye on it. The heater is an older 16k btu Suburban Propane monstrosity which takes up far more under-cabinet room than I like. Eventually we're going to be undertaking a complete interior renovation, at which time the heater will be swapped out for either a vented catalytic unit or, if I win the lottery, a Webasto Dual Top Evo.

I just placed an order for some more fuel system parts which I'll be installing over the next couple weeks. The lift pump is old and needs replacement, and both tanks need to be dropped, cleaned, and generally restored to better-than-new condition. I can't say I'm looking forward to dropping both tanks, but it needs to be done.

Oh, and so far so good with the rear box vent. We had rain over the weekend and the box remained as dry as I thought it should be. The real test will be when I introduce water back into the box from the miscellaneous hoses and whathaveyou that I store back there.

SG

The weather this past weekend was a little on the cold side which gave us the opportunity to use the cabin heater. Strangely, I had a couple instances of the unit not lighting which was a new problem. The heater is ignited with a little transformer and a couple probes. I removed the probes, cleaned them up with 600g sandpaper and reinstalled. Everything seems to be working again but I'll be keeping my eye on it. The heater is an older 16k btu Suburban Propane monstrosity which takes up far more under-cabinet room than I like. Eventually we're going to be undertaking a complete interior renovation, at which time the heater will be swapped out for either a vented catalytic unit or, if I win the lottery, a Webasto Dual Top Evo.

I just placed an order for some more fuel system parts which I'll be installing over the next couple weeks. The lift pump is old and needs replacement, and both tanks need to be dropped, cleaned, and generally restored to better-than-new condition. I can't say I'm looking forward to dropping both tanks, but it needs to be done.

Oh, and so far so good with the rear box vent. We had rain over the weekend and the box remained as dry as I thought it should be. The real test will be when I introduce water back into the box from the miscellaneous hoses and whathaveyou that I store back there.

SG

Last edited:

Similar threads

- Replies

- 1

- Views

- 508

- Replies

- 16

- Views

- 3K

- Replies

- 1

- Views

- 678

- Replies

- 1

- Views

- 847