ntsqd

Heretic Car Camper

Those particular hinges are designed to be oriented vertically, but I do not see why they couldn't be used as you need.

How robust does the hinge need to be? How much slop can the system withstand?

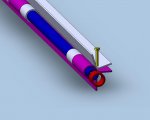

My first thought for a robust hinge would be nested round tubes. Use a 1" OD x .125" wall tube as the pivot 'pin' and alternately weld short sections of 1.25" OD x .125" wall tube to the upper and lower mount parts. I wouldn't do alternating all the way across the width, just 4 or maybe 6 sections placed so that the lid can not slide sideways on the pivot.

Weld a ~.5" long section of the 1.25" tube to one end of the 1" tube. At the other end place another piece of ~.5" long 1.25" OD flush to the end of the 1" OD tube and drill through both of them for a bolt hole. Ideally you would then drill the 1" slightly bigger and weld in a sleave and grind smooth to the OD.

Removing the lid would consist of removing the bolt, then the short piece of 1.25", and pull the 1" out of the alternating 1.25" tube sections.

How robust does the hinge need to be? How much slop can the system withstand?

My first thought for a robust hinge would be nested round tubes. Use a 1" OD x .125" wall tube as the pivot 'pin' and alternately weld short sections of 1.25" OD x .125" wall tube to the upper and lower mount parts. I wouldn't do alternating all the way across the width, just 4 or maybe 6 sections placed so that the lid can not slide sideways on the pivot.

Weld a ~.5" long section of the 1.25" tube to one end of the 1" tube. At the other end place another piece of ~.5" long 1.25" OD flush to the end of the 1" OD tube and drill through both of them for a bolt hole. Ideally you would then drill the 1" slightly bigger and weld in a sleave and grind smooth to the OD.

Removing the lid would consist of removing the bolt, then the short piece of 1.25", and pull the 1" out of the alternating 1.25" tube sections.

Attachments

Last edited: