Now it's time to start the canvas!

I’ve actually had the fabric for quite a while now. I bought like 6 yards of bright orange vinyl coated polyester and 2 yards of black for “just in case” and “oh crap I want a cover for this thing!” I chose 18oz weight because that’s apparently what most pop up campers are using, so it seemed like a safe bet. It’s actually a lot more flexible and thin than I thought it was going to be, but it should fold nicely inside the camper. I also keep calling it “canvas” but, like I said above, it’s vinyl coated poly. This means it’s completely waterproof, super rugged, and won’t rip.

Mytarps.com, where I bought all this stuff, has great prices and a huge selection of fabric.

The first step was to take the orange canvas and cut it in half lengthwise. It comes 61″ wide and the height I need is 28″. Worked out pretty perfectly!

My plan is to get all 4 sides done, and then sew them together. I’m doing this all on our kitchen table, which is big, but not big enough for all of that! So… multiple pieces it is!

The first step to actual sewing (besides obsessive amounts of measuring), was using the basting tape (essentially ************ double sided tape…) to hold my fabric down so I can sew it. Apparently you use this stuff instead of pins when you have heavy duty fabric or waterproof fabric… and I have both!

I have a helper...

I had to watch an entire youtube video on how to set up the thread on my new Sailrite sewing machine...

Some test stitches to get used to my new toy...

To start I hemmed both sides to make the width exactly 28" tall.

Did that for all 4 sides and labeled them so I don't get them mixed up!

If I didn't want windows, I could have sewn all 4 sides together and been done, but I want big windows... so here we are!

(no big family dinners until I'm done sewing!)

The tutorial I’m following is actually for windows in the clear plastic of a boat enclosure. Since I can’t see through my material, my plan was to make a pattern and then draw the same shape on both sides of the fabric. The first step in this devious plan is to actually make a pattern. I had a sheet of plywood/laminate/cardboard that was used for shipping something. (don’t remember what). I figured it would work great. The tutorial also recommended a minimum radius of 8″… so I went with 10″ just so I had less issues with the corners.

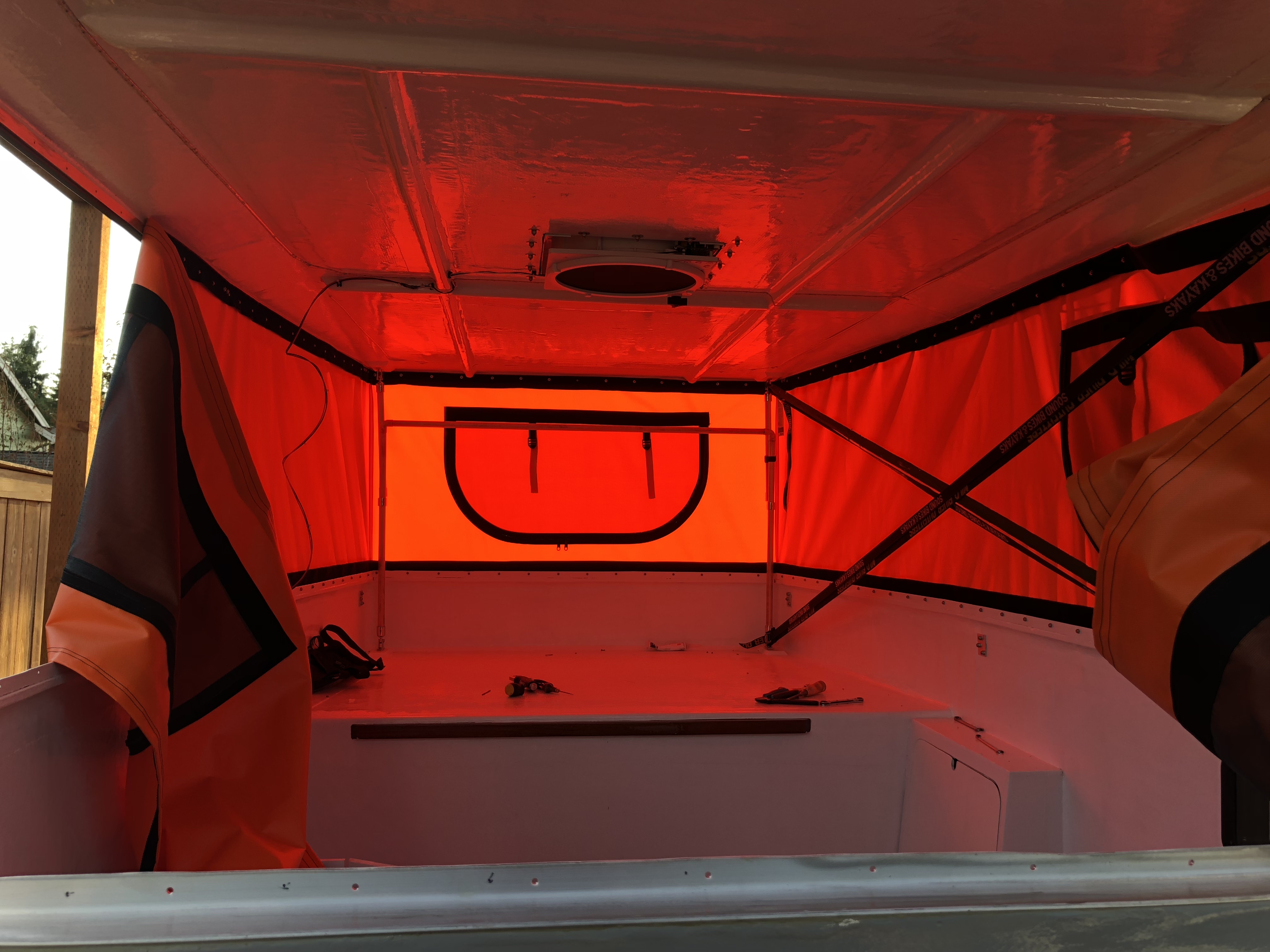

There are going to be 4 big D shaped windows.

They're going to be BIG!

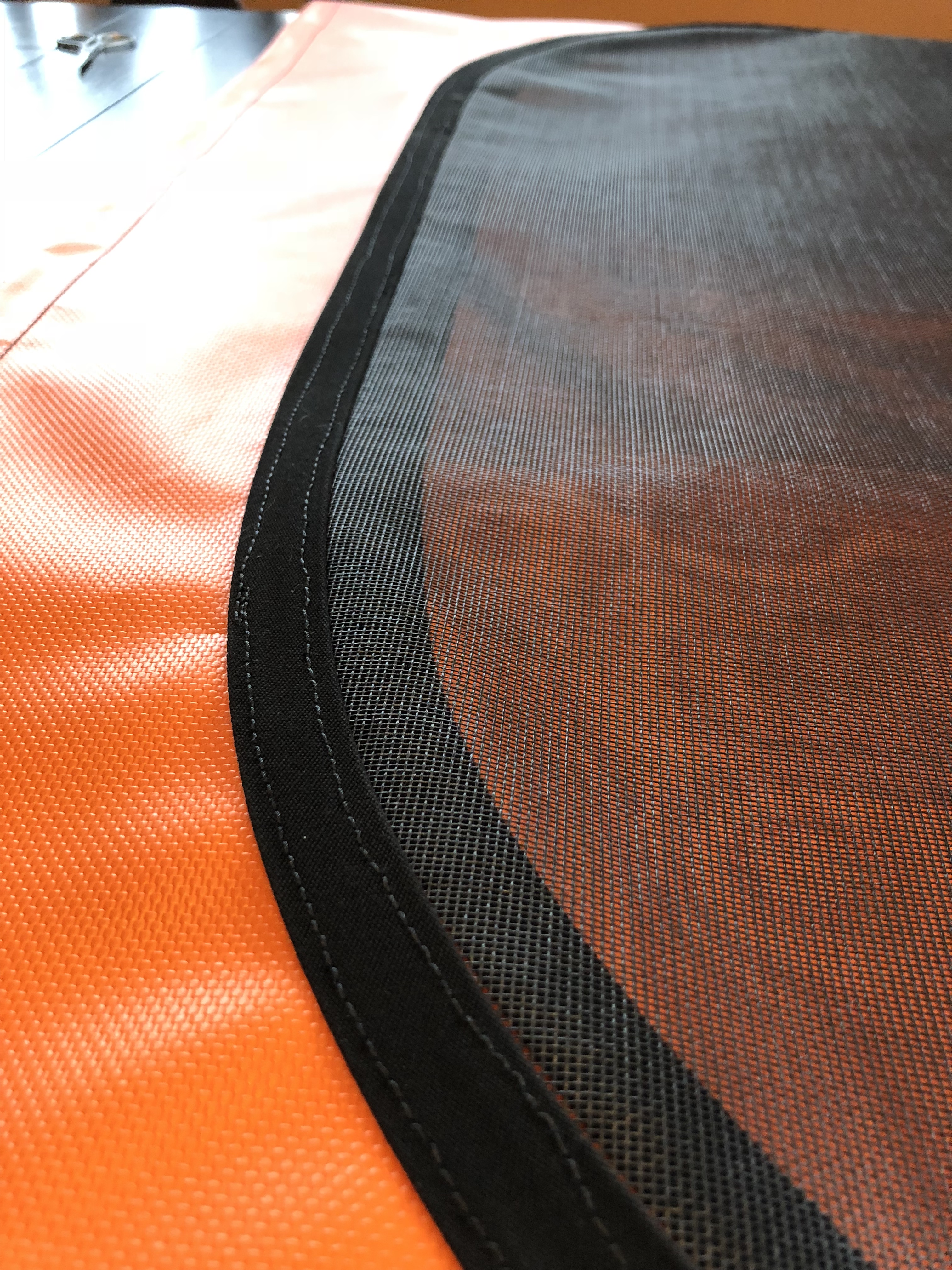

I marked the window on both sides of the fabric and then used the bias tape to attach the bias tape

Sewing it on

Now it’s time to sew the zipper in. I started by putting basting tape on both sides of the zipper and then very carefully aligning it with the tape on the other side. The zipper will curve around the radius, but it gets a little awkward.

The seam for the zipper on one side matches up to the other edge of the bias tape on the other side. Pretty slick.

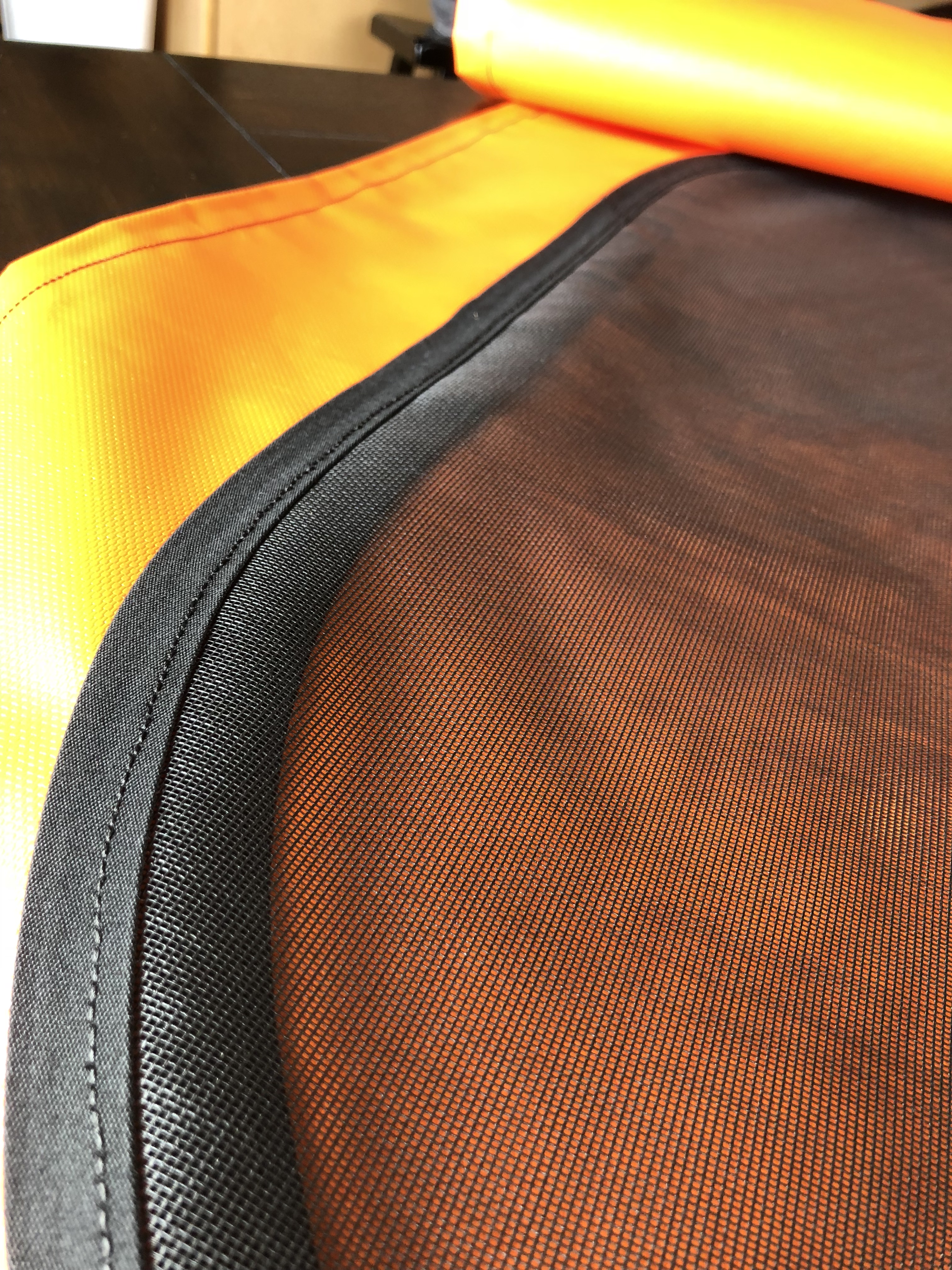

I definitely wanted mesh screens to keep bugs out!

Cut to fit

Bias tape on the other side of the screen

The hardest part was trying to mark on this side where the two pieces of bias tape meet on the other side so I can use it for a reference. I didn't quite get it. The tutorial I was watching was for windows on clear vinyl for a boat enclosure. It's a little harder when you can't see through your material.