luthj

Engineer In Residence

Initial work on this subject is over here.

www.expeditionportal.com

www.expeditionportal.com

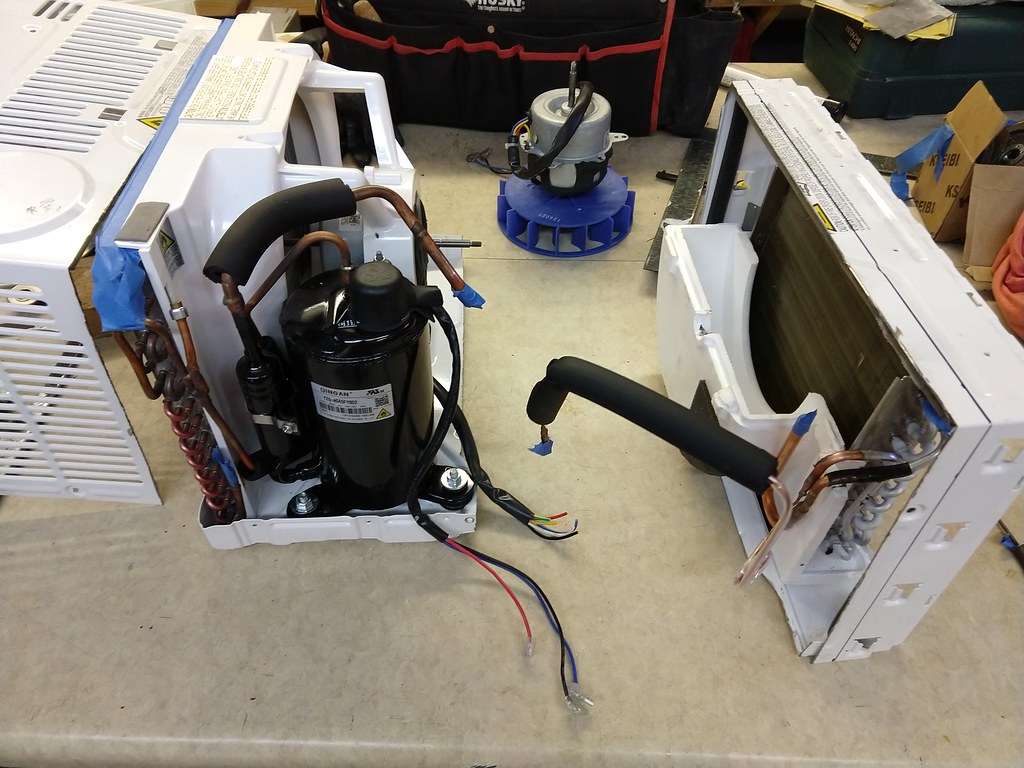

The short of it, I am trying to build a Split AC system in the ~5,000btu range. Limited space, cost, and running occasionally from battery power drove me towards building my own.

I am starting with a 5,000btu mechanical window unit.

I am going to cut in half approximately on this line.

Since the fan is shared between evap and condenser, I bought a used fan for the evaporator.

The plan is to put the compressor and condenser under the van in this space.

I have a pile of copper fittings and some refrigeration copper tubing. Hoping to get the sections separated today. Then I will fabricate some sides to rebox the two halves. The evap unit will also need a bracket to mount the motor.

Another issue is sealing the motor on the outside unit. It will be exposed to dust and moisture. Neither end of the shaft has a seal. One side can just be capped, as I will be cutting the unused shaft off. The other side is 8mm, I think there is room to glue a shaft seal to the motor housing, and then seal the wire penetration. That should eliminate issues with dust/moisture.

Overland Sprinter Build

No worries, just explaining why I came to my decision. You can have two of the following in overland vehicles, pick wisely. Lightweight Easy to Use Inexpensive

www.expeditionportal.com

www.expeditionportal.com

The short of it, I am trying to build a Split AC system in the ~5,000btu range. Limited space, cost, and running occasionally from battery power drove me towards building my own.

I am starting with a 5,000btu mechanical window unit.

I am going to cut in half approximately on this line.

Since the fan is shared between evap and condenser, I bought a used fan for the evaporator.

The plan is to put the compressor and condenser under the van in this space.

I have a pile of copper fittings and some refrigeration copper tubing. Hoping to get the sections separated today. Then I will fabricate some sides to rebox the two halves. The evap unit will also need a bracket to mount the motor.

Another issue is sealing the motor on the outside unit. It will be exposed to dust and moisture. Neither end of the shaft has a seal. One side can just be capped, as I will be cutting the unused shaft off. The other side is 8mm, I think there is room to glue a shaft seal to the motor housing, and then seal the wire penetration. That should eliminate issues with dust/moisture.

IMG_20200712_155105466

IMG_20200712_155105466 IMG_20200712_161611132

IMG_20200712_161611132