How far would you be willing to go past the top of the windshield on a Isuzu or Mitsubishi cabover truck for a camper overhang?

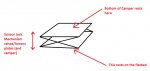

It is 54 inches from the back of the headache rack on our Isuzu NRR flatbed to the top of the windshield where it starts to curve. I would like to go 72 inches on the length of the camper overhang (most slide in truck campers are more like 85 to 90 inches!).

Also, what gap would you leave between the top of the truck cab and the bottom of the camper overhang? I am leaning toward 4 inches. Thanks.

It is 54 inches from the back of the headache rack on our Isuzu NRR flatbed to the top of the windshield where it starts to curve. I would like to go 72 inches on the length of the camper overhang (most slide in truck campers are more like 85 to 90 inches!).

Also, what gap would you leave between the top of the truck cab and the bottom of the camper overhang? I am leaning toward 4 inches. Thanks.