shortbus4x4

Expedition Leader

Wow, amazing build you're doing. I used to drive and work on HMMWV for Uncle Sam when I was a young man. Never would imagine a cabover on one!

Get your tickets to THE BIG THING 2026!

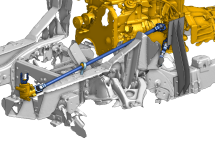

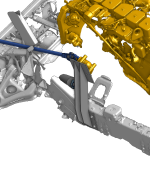

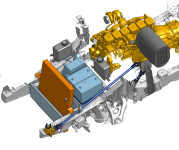

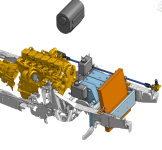

The engine is in the stock HMMWV 6.5 location yes, there is a differential and frame crossmember ahead of it which limits how far forward it can go without raising it another foot. I opted to go with the lower and further back position to keep the CoG low, but also because it's much easier from a fabrication perspective. The driveline is definitely further back compared to other cabovers, but it isn't unreasonable when you model the living space and where the floor lands. The frame rails having a drop in the center also makes it look like it protrudes into the living space more than it does in reality. Hopefully my previous post answered what I'm doing with the free space in front, although I considered a burrito warmer behind the radThis is a very interesting build. I have seen a 6BT on an engine stand and it isn't small, neither is an LCT1000. Is the current location where the GM 6.5 V8 was? It seems by looking at the pictures that the driveline is quite far back, which is great for weight balance, but terrible from a use of space standpoint (length). What was your reason for placing the engine so far back and what will you do with the forward "engine" space?