zioxkoa

Member

I've been working on this project on and off for almost two years now, so I figured it was about time for a build thread.

Introduction

Why a HMMWV (Humvee/Hummer H1/etc)? Lots of reasons, some more personal preference than others, but in no particular order:

Fair warning, when buying a military surplus HMMWV, there's a lot of variants and none of them have any kind of "standard equipment". Essentially big rolling boxes of chocolate. I ended up winning an auction for a M1152 ECV 15.5k GVWR non-runner (more on the drivetrain swap below) for $7700 in December 2020. These are typically the up-armored variant which is then un-armored in the demilitarization process. After 3 months of background check/bureaucratic paperwork, I was finally able to take receipt of the truck in March 2021. Here's how it looked the day I got it:

As Mr. Solo once said, "She may not look like much, but she's got it where it counts".

Drivetrain Swap

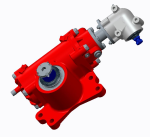

I got this truck as a non-runner because I knew I didn't want to keep the stock (gutless) GM 6.5 turbodiesel and 4L80e. They aren't known for their reliability, power, serviceability, or anything good really. A common swap into the Humvee is a Duramax/Allison combo (which was a factory option in the H1 Alpha), but I opted for a 12 valve Cummins 6BT because I prefer the fully mechanical nature of the engine. I went with an Allison 1000 since I wanted a double overdrive transmission with TC lockup in every gear for comfort and efficiency. In August 2021 I was able to find a used 12v Cummins from a friend for a good price, and an Allison 1000 on Craigslist. The engine ran fine, but with the amount of work going into this build I decided to give it a full rebuild/reseal. Before/during/after pics:

While it was apart I checked all tolerances, everything was well within spec which was great news! At the same time I sent the Allison off for a rebuild at the local transmission shop. After it came back, I swapped the shift lever and valve body to convert it from a 5 speed to a 6 speed (all the internals are the same between 5 and 6 speed Allisions, 6th is just a combo of two existing clutches). I don't have many pictures of that process but happy to share more if anyone is interested. Around the same time I also pulled the old drivetrain out of the truck which ended up being a huge pain because I decided to do it on gravel... You live and you learn I guess. Also, there's enough clearance to where you can roll the chassis over its own transmission with no interference, which was fun

After the fiasco of pulling a drivetrain on gravel I caved and rented some shop space for the duration of the project. While transporting the truck I was able to get a dry weight in the current configuration (raw body on frame with no drivetrain): 4420 lbs. Adding 1500 lbs back for drivetrain will put it around 6k, then doors/glass/comfort plus a lightweight body should be able to sneak under 10k, hopefully.

Also, some detail on why I want to stay under 10k lbs: using this calculator for some back-of-the-napkin contact patch measurements, with a weight of 10k lbs on 40" tires aired down to 21 psi there's ~4" of deflection in the sidewall and a ground pressure of ~11 psi. Compared to a human's average ground pressure of 16 psi it makes for a good reference point when driving over mud, sand, and deep snow.

I've hit the 10 picture limit here, continued on the next post...

Introduction

Why a HMMWV (Humvee/Hummer H1/etc)? Lots of reasons, some more personal preference than others, but in no particular order:

- portal/CTIS hubs

- independent front and rear suspension

- 70mph capable

- 15.5k lbs GWVR variants

- low COG

- high clearance (~16" to diff stock)

- readily available (for US citizens)

- AWD with locking 4x4

- front and rear Torsen diffs

- fully boxed frame rails

Fair warning, when buying a military surplus HMMWV, there's a lot of variants and none of them have any kind of "standard equipment". Essentially big rolling boxes of chocolate. I ended up winning an auction for a M1152 ECV 15.5k GVWR non-runner (more on the drivetrain swap below) for $7700 in December 2020. These are typically the up-armored variant which is then un-armored in the demilitarization process. After 3 months of background check/bureaucratic paperwork, I was finally able to take receipt of the truck in March 2021. Here's how it looked the day I got it:

As Mr. Solo once said, "She may not look like much, but she's got it where it counts".

Drivetrain Swap

I got this truck as a non-runner because I knew I didn't want to keep the stock (gutless) GM 6.5 turbodiesel and 4L80e. They aren't known for their reliability, power, serviceability, or anything good really. A common swap into the Humvee is a Duramax/Allison combo (which was a factory option in the H1 Alpha), but I opted for a 12 valve Cummins 6BT because I prefer the fully mechanical nature of the engine. I went with an Allison 1000 since I wanted a double overdrive transmission with TC lockup in every gear for comfort and efficiency. In August 2021 I was able to find a used 12v Cummins from a friend for a good price, and an Allison 1000 on Craigslist. The engine ran fine, but with the amount of work going into this build I decided to give it a full rebuild/reseal. Before/during/after pics:

While it was apart I checked all tolerances, everything was well within spec which was great news! At the same time I sent the Allison off for a rebuild at the local transmission shop. After it came back, I swapped the shift lever and valve body to convert it from a 5 speed to a 6 speed (all the internals are the same between 5 and 6 speed Allisions, 6th is just a combo of two existing clutches). I don't have many pictures of that process but happy to share more if anyone is interested. Around the same time I also pulled the old drivetrain out of the truck which ended up being a huge pain because I decided to do it on gravel... You live and you learn I guess. Also, there's enough clearance to where you can roll the chassis over its own transmission with no interference, which was fun

After the fiasco of pulling a drivetrain on gravel I caved and rented some shop space for the duration of the project. While transporting the truck I was able to get a dry weight in the current configuration (raw body on frame with no drivetrain): 4420 lbs. Adding 1500 lbs back for drivetrain will put it around 6k, then doors/glass/comfort plus a lightweight body should be able to sneak under 10k, hopefully.

Also, some detail on why I want to stay under 10k lbs: using this calculator for some back-of-the-napkin contact patch measurements, with a weight of 10k lbs on 40" tires aired down to 21 psi there's ~4" of deflection in the sidewall and a ground pressure of ~11 psi. Compared to a human's average ground pressure of 16 psi it makes for a good reference point when driving over mud, sand, and deep snow.

I've hit the 10 picture limit here, continued on the next post...