Got started on a few projects today. First, started the rear bumper; today was pretty much running errands and removing the stock bumper/hitch, and trimming the bed for the new bumper.

I'm no stranger to cutting sheet metal off of a vehicle, so this didn't particularly phase me. But the ridiculous amount of metal you've got to cut through on the corners is a headache.

Also, all I had today was my camera phone, so these pictures are teh suck.

Once everything was removed and I had clear access to the frame, I got started with some bumper mounts.

I'm going to make a "template" mount, that way if I ever want/need to build another bumper for anyone in the future I'll have the basis on which to do so easily. I also decided I'm going to add at least one additional bolt to the mounting plates on the frame rail, potentially two. I might also get some extra material and weld a crossmember in between the frame rails on the back end. Dunno yet. Either way, the 'template' will have some 3/32" or 1/4" holes drilled in it at the locations of the bolts, and the outer dimensions needed for the mounts, that way I can line it up with the new material in the future and punch the holes through, then enlarge with the step bit to the required size.

The truck looks a little weird without an ***. A little later in the afternoon I went to another parts store and picked up some door edge guard for the cut edge; it cleaned up the look substantially.

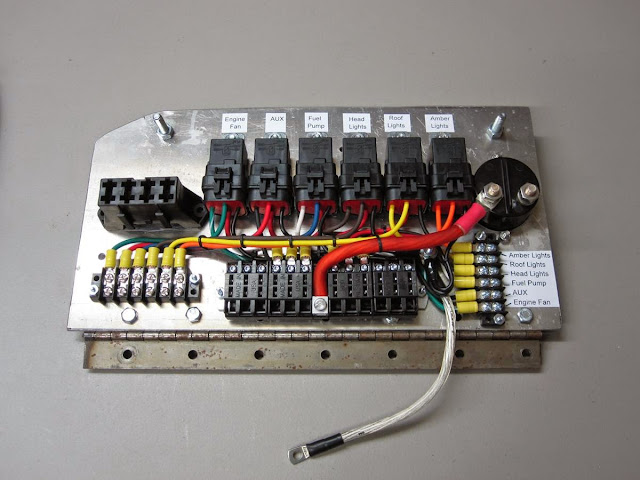

I may have mentioned this before, but while the wiring of aftermarket crap on my jeep

worked, it didn't look good, nor was it organized in any sense of the word (ok, it was, but no where near what I would expect of myself). In ordering lights, etc., I've also ordered parts to build a proper relay and fuse panel, so everything is in one location, easily organized, serviced, and diagnosed for issues.

Getting started on the panel with a 12" square piece of 3/8" HDPE. I chose HDPE because it's non-conductive, corrosion-resistant/proof, and extremely easy to work with. But mostly because it's non-conductive. All the hardware on this is stainless steel, as well.

All it needs now is some wires. Input will be fused 150a into the fuse panel, signal wires from the switches in the cab to the relays on the right, power from the relay to the device is on the left, with a group ground adjacent to the fuse panel. All the relays' grounds will be looped together in a row to keep things clean, and each relay is held on securely with a wing nut on a carriage bolt which is jammed into the HDPE, so there's a non-permanent way of mounting the relays so they can be replaced without the need of tools in the field.

That's all for now. Tomorrow I'm going back to my parents garage to continue working on the bumper, and will be picking up additional material to make a second bumper for a guy on TacomaWorld.