This really needs a thread of its own as the rules are very different when both batteries are the same voltage or the same formulation. Remember. we are talking battery maintenance, NOT self-jumping.

So, assuming:

-- 24v start battery

-- 12v camper battery

-- Camper battery is lithium iron. (This really only impacts the profiles, not the concept.)

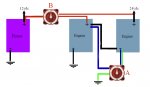

THEORETICALLY, you can let each battery to battery charger (B2B) run by its own rules. Practically, the gurus that I spoke with (bunch of folks who talk funny, wear hats with lopsided brims, and actually manufacture B2B's insist that you need a positive control to avoid any danger of a runaway loop, or feedback. So.

Step One, B2B from 24v start to 12v camper/house/etc. This is fairly simple. Sterling and REDARC both make models that can do this and, I understand, so does Victron.

If you are traveling, this is all you need, as you will probably run the truck engine at least once a week and that will keep the start battery happy.

Park for a few weeks between trips, or put the truck into winter storage, etc., and now you have to worry about both battery banks. For this argument, we will assume that your solar or shore is adequate for the camper, we just want to share with the starter. One, easy option is a small, clip on shore or solar charger of the appropriate type.

But we want to do more and make it auto magic. So,

Step Two, another B2B, 12v camper to 24v starter. Again, Sterling, REDARC, and, I assume, Victron will sell you this.

The danger comes if the camper battery is above the turn on voltage of the B2B pointed at the starter battery while, at the same time, the starter battery is above the turn on voltage of the B2B from the start to the camper. Now you can have a loop with each charger trying to satisfy the other. How much of a practical danger this is, I don't know. I would imagine that it can be made a bit worse with a much larger camper battery. It seems that if your shore or solar charger added enough power, then eventually each battery would hit "full" (as per the profile of each charger, and each would turn off.)

How do I deal with this? (And this has worked for years.)

-- There is a brick wall relay between the starter battery and the input to the primary (starter to camper) B2B. This relay only turns on when the ignition is on. (It is controlled by the switch, not the actual state of the engine.) If the relay is closed, then the B2B turns on of off, depending on its profile. This is easy.

-- There is another, normally closed relay that controls the second B2B. In my case, it is wired on an ignition trigger wire, but that is unique to the particular model of REDARC I am using. You could also wire this relay to simply shut of the connection to the camper battery. When the ignition turns on, the relay opens and this B2B is thus turned off. At this point, the starter battery is charged by the alternator.

The relay that I am using is a 24v "crossover" relay. So, when it is energized, the input contact moves to the other output and, because there is nothing there, it has the effect of opening the circuit.

Possible point of failure? The turn on voltage for the 12v>24v charger is 13.2v (classic lead acid) and the lithium battery is typically at 13.3v+. With an 800Ah camper battery, this has not been a real issue, especially as the starter battery is almost always only floating, but it does probably add about 1A to my background load.