IHDiesel73L

Adventurer

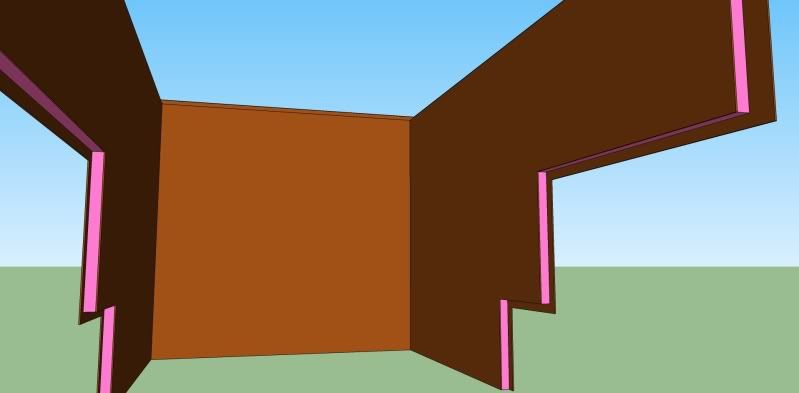

If you're doing luan plywood over a foam core and bond them well I think you'll be surprised at how sparse you can be with actually framing members. The cabover is entirely geometry driven, length and sidewall height being the main ones. Again though with the solid wall panel you'll have a lot going for you, in the side walls it'll act like the web of an I beam so then on the top/bottom of that section you just need the right amount of your chosen framing material to handle the tension (on the top) and compression (on the bottom). Since you're talking about steel it realistically won't take much. Again this assumes you solidly bond your wall panels and use them structurally (they need to tie into your framing solidly, not just be affixed to it).

So in order for the panels to provide strength to the frame you need to do more than simply bolt them on. Let's say you were doing an angle iron frame with the flats facing out toward the panels. Would it be wise to bolt AND glue the panels to the frame then apply epoxy at all seams (inside and out)? I would think that would be the only way to make the outer panels function as a one piece shell. Am I at least getting warm?