I seem to recall a few years back that someone was making plexi inserts for the freedom top and then they weren't. A trawl of the internet gave mixed reviews about priced too high and scratches & cracking of the panels as well as possibly leakage issues where the glazing and freedom panel join.

You might be referring to Jeetops. A search reveals that they've had a lot of issues with leaking and cracking, and I read that they filed a lawsuit against the manufacturer of the adhesive they used to bond the plexiglass to the Freedom Panel. As far as I know they are still in production, although Quadratec used to carry them in their catalog and no longer does.

One design error I've seen in some production uses of bonded windows is failing to have a provision for shielding the adhesive from UV. Look at your Jeep's windshield or the side windows on the hardtop - there's a black "painted" band on the inside of the glass where the adhesive goes, the main purpose of that coating is to prevent UV light from reaching the adhesive. If the adhesive isn't protected from UV, it will fail over time.

Mine will use tempered glass, there are far fewer problems with glass than with plexiglass. Even if plexiglass/lexan/acrylic did seal properly and didn't crack (which I'm sure it could do with proper engineering), it scratches very easily and over time gets hazy with exposure to UV - being on the top of the roof would make exposure to UV pretty much constant. Tempered glass is no more expensive in reasonable production quantities than the various plastic options, and in many cases is less expensive (sort of off-topic - I can't understand why Smittybilt used plastic for the Alpine windows of their new "Safari Hardtop" for the JK. ok, back on topic...).

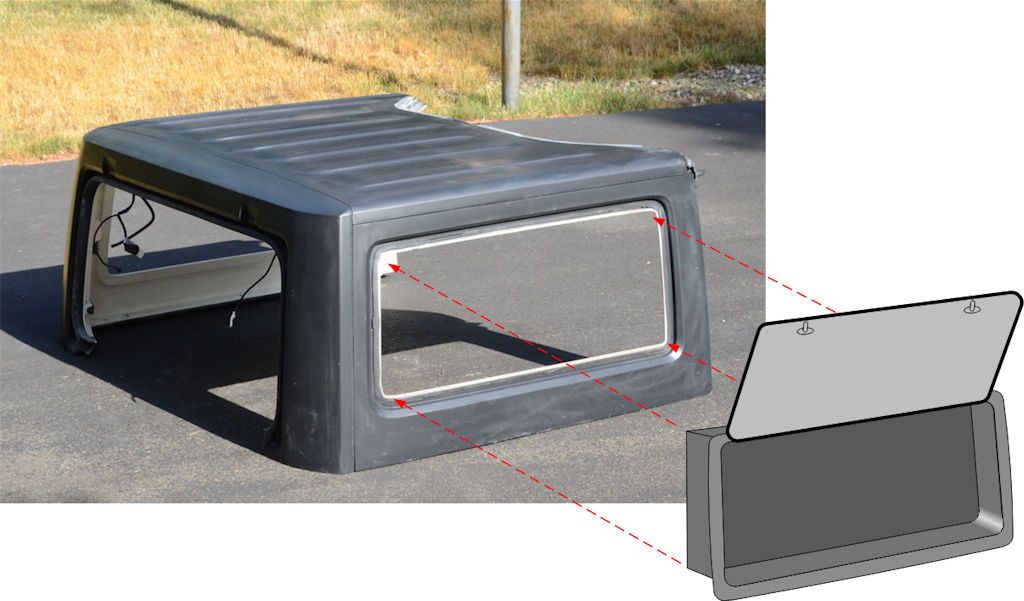

Whether you're doing fixed skylights like Jeetops or openable ones like I'm doing, It's really not hard to do them so they don't leak or deteriorate over time. It's pretty basic automotive engineering. Since mine are designed to open, I've designed them to use automotive materials and practices that have been used on flip-open vent windows for decades. Same as I've done on the JK Safari Cab flip-out vents (the engineering and design of which was borrowed from the late '70's Toyota FJ40 and also the skylight design has some parts borrowed from the '90's Ford F150 extended cab vent windows)...

I myself would love a nice set of light green tinted lights in tempered glass paired with a matched cloth section on the inside, 3M dual lock to secure it when you want the shade or roll it up and stow it when you don't.

I haven't decided if I'll implement shades on this prototype or not. I've got a few ideas for securing cloth shades on the inside. A simple way to do it would be to use snaps or twist-lock fasteners, or they could be secured with velcro, or there are a few other curtain fastening systems from the marine worls that would work.