I really like the exoskeleton they did... is that your plan? You good with CAD? I'd be curious to know what that would cost. I guess they also got the panels CNC cut?

If you only have the aluminum on the outside and no inner reinforcement it makes sense to use thicker material. 3/16 seems about right.

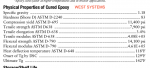

If this is representative, it's quite weak compared to the PVC foam. https://www.carbon-core.com/pdfs/pds-carbonfoam-pu-pir.pdf

I'm decent with CAD. It's part of my job so I use it a fair bit. I plan to cad up my whole subframe/exo/body. I've actually already got a rough model of the truck that I've been using to size the body.

Yeah I like the alu on the outside only, like everlanders and turtle V did.

Those foam compressive strength numbers are similar to what I linked so I bet the rest are close. While the 90 psi comp strength at 4lb/cf doesn't scare me the ~2000 psi comp modulus does compared to the ~6000 of PVC foam. I wonder what XPS is. I'll google it tomorrow. If it's better than XPS, not much concern. Cause the cost is comparable to $40 2" XPS sheets with better strength so if the bond is good you're golden. Saves on epoxy cost also because you could cast it onto the foam. At least that's what I interpreted the datasheet to say about the VR2 panel's cloth backing.

Edit: 40 psi XPS is 1400 psi compressive modulus, 60 is 2200, and 100 is 3700.

It's dangerous for me checking the forum at night

@Terra Ops Thanks for the link to the other page. Definitely some good info to look at there. That bridge composite panel link could be interesting.

Last edited: