@Watersmeet Thanks for checking that out. Sad to hear it's not available. Looks like a cool product. I wonder if honeycomb could be sourced and then have a pour foam poured into it and trimmed flush. Could end up being a tedious process though.

@rruff those pultrusions are really cool! I wish they came in non 90* angles though. I'm planning to go with 3/16 custom bent alu on mine (like everlanders). Maybe if there is a significant cost difference I would try 1/8" but I'm betting the largest driver of cost is gonna be the bending.

I linked my sheet's datasheet earlier (VR2 from US Liner Co.). Seems like it has slightly higher tensile stiffness and much higher strength than what Terra Ops used. Mine are 1.6mm thick vs his at 2mm thick though.

G60/30: 110 MPa Tensile Strength, 8.4 GPa Tensile Modulus

VR2: 230 MPa Tensile Strength, 10.34 GPa Tensile Modulus

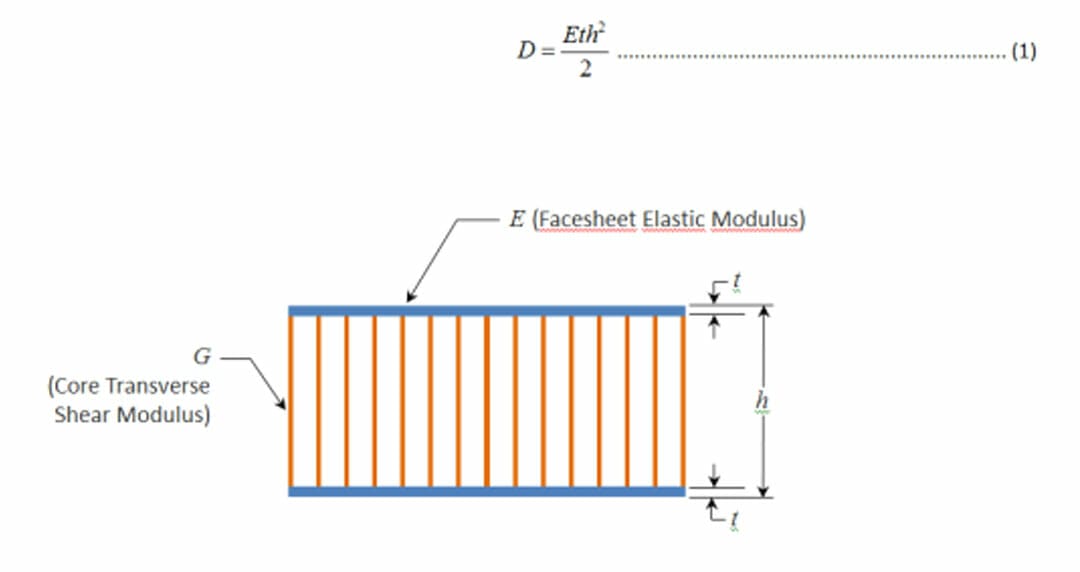

I had always thought it was the exterior sheet's tensile stiffness (modulus) that mainly determined the stiffness of the panel so I googled for an article to cite and came across this interesting one disproving me. I'll admit to skimming the math completely

but I think the points made in the article are good.

Understanding the true behavior of sandwich structures related to stiffness under in-plane and out-of-plane loading | An example of estimated deflection and core shear stiffness

www.mayahtt.com

"Increasing the facesheets’ thickness is the least effective method of achieving a rigid sandwich (not the mention the cost involved, especially when dealing with

composites). In practicality, the optimal sandwich structure will be a judicious combination of core thickness and core stiffness."

This just brings me back to really wanting to try some 40 or 70 psi pour urethane foam.

Ok, ok I have to get some work done today lol. Really enjoying discussing this.

-Derek