interesting idea. nice "vice work"......are you going to seal that plywood before it warps? any plans for some metal frame/banding work around the perimeter and some sort of ribbing?

some router work.....

http://brunnerent.com/Tools/Portfol...size=0&lngDisplay=0&jPageNumber=9&strMetaTag= or

http://www.brunnerent.com/Tools/Por...size=0&lngDisplay=0&jPageNumber=3&strMetaTag=

The plywood is sealed, but as with most wood it still warps a bit. The boards I used have a very predictable warp to them, which I used convex-up to actually assist with tent strength.

I am still going back and forth regarding framing the bases or not. I'm actually leaning towards using a velcro peremeter to attach the tent material. I think it will make tension adjustments easier, and if the tent ever needs to be washed/mended/modified, it would be easier to unvelcro the tent in order to remove it from the base.

On to some updates from the weekend. A lot of work, but it doesn't LOOK like a whole lot. A lot of seat-of-the-pants engineering work going on.

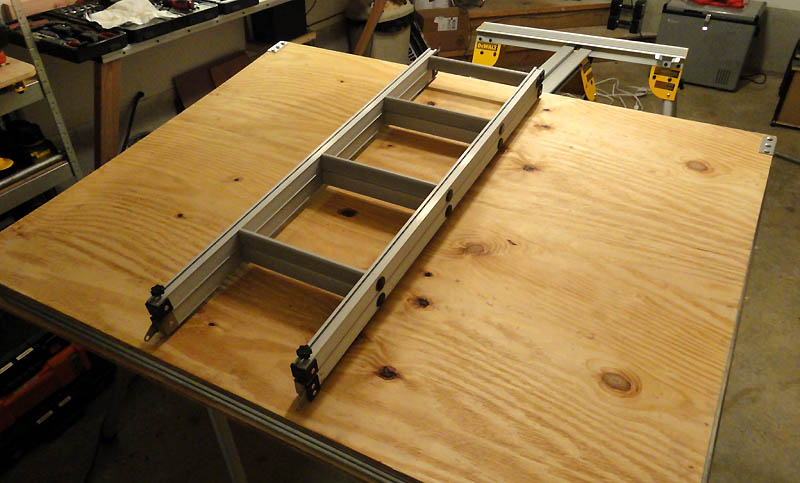

Support hoops trimmed to the proper lengths, adjustment knobs added.

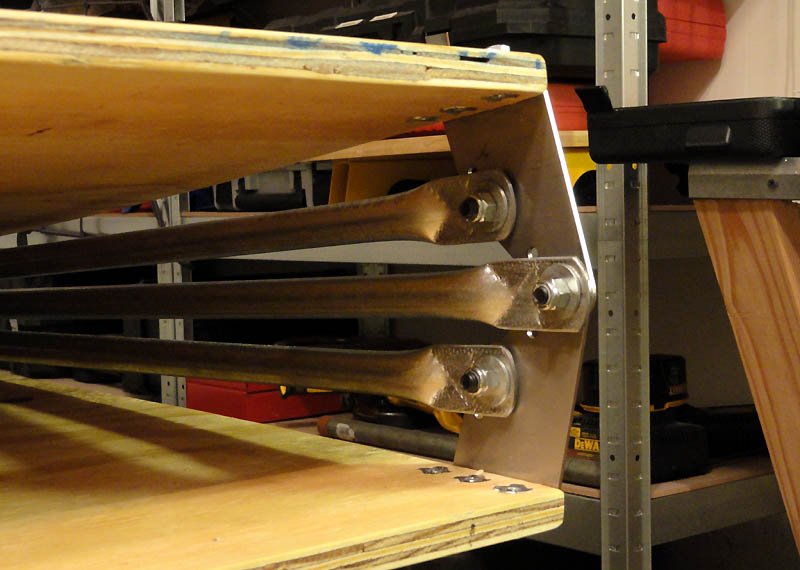

Hinge and support hoops when the tent is folded up. Looks nice and neat.

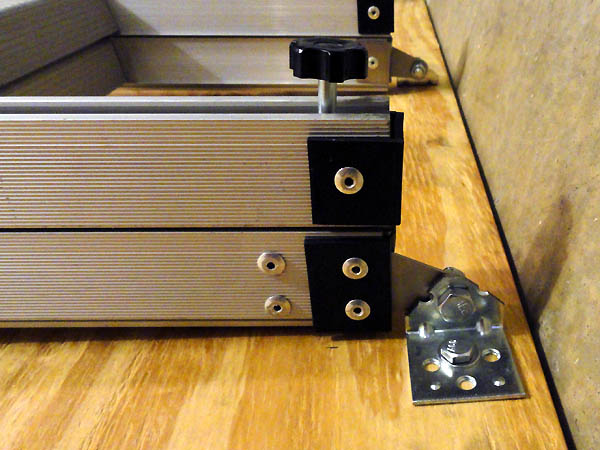

Quickly laying out the ladder to see where the brackets will need to sit. (I still need to make the ladder brackets, not enough time in a weekend to do everything.)

Through my testing so far, I noticed the cantilevered base section bowed under my weight much more than the base that is anchored to the roof. With my full weight, I could stick my fingers through the opening that was created between the bases. So it was not only a pinch point, but a weak point in the design too. So I added an aluminum support lip so the anchored base so it shares the load with the cantilevered base. So far it's working great, especially since it's essentially a bandaid that I didn't originally expect to need.

Since I'm using a lighter polyester, and not a heavy canvas for my cover (and since it will not be fully stretched upon unfolding), I saw the possibility of hyper-extending the main joint. That could cause reliability issues, so I created a suspension support to help hold the weight of the cantilevered section. This will prevent pulling a seam or breaking the hinge. The main support will actually come from the ladder, but these should be a good aid, especially when setting the tent up.

Detail of the nylon abrasion insert in the support tube.

I also got a good start on the tent mounting points, but it needs more work. I'm hoping to have the whole structure mounted and tested on the truck later this week. It's slowly getting there. The real challenge will be the tent material itself.