You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

FG140 Subframe/Flatbed build

- Thread starter Bajaroad

- Start date

body mounts

I'm concerned about your body mounts. It appears that they are bolted onto the sides of the frame rails in a manner that carries the weight of the camper on the bolts that pass horizontally through the body mount and the frame.

The Mitsubishi body builders guide says the weight of the camper sub-frame should rest on top of the truck chassis. The bolts should position the sub-frame on the chassis, but not be the major load-bearing element

The company that built Michel Szulc Krzyzanowski's Fuso camper used the bolts are the weight bearing element. The bolts failed after relatively few miles.

I hope I'm mis-interpreting your photos!

Chip Haven

I'm concerned about your body mounts. It appears that they are bolted onto the sides of the frame rails in a manner that carries the weight of the camper on the bolts that pass horizontally through the body mount and the frame.

The Mitsubishi body builders guide says the weight of the camper sub-frame should rest on top of the truck chassis. The bolts should position the sub-frame on the chassis, but not be the major load-bearing element

The company that built Michel Szulc Krzyzanowski's Fuso camper used the bolts are the weight bearing element. The bolts failed after relatively few miles.

I hope I'm mis-interpreting your photos!

Chip Haven

Bajaroad

Adventurer

Concerned?

Chip - If you look at the WHOLE page from the manual, you can see this is an acceptable approach. Why be concerned if you don't know the load?

How did you mount yours? Please post pics.

The bolts are not in shear, but even if they were they could handle the load - 6 X 3/8- Grade 8 (each side). I'm also distributing the load to the middle of the frame using air springs. The resultant load on each front mount may be as low as 1klb. I'm using aluminum for construction and targeting a "light weight" camper.

Michel's rig is not mine. His attachments were in pure shear and were not properly engineered.

Chip - If you look at the WHOLE page from the manual, you can see this is an acceptable approach. Why be concerned if you don't know the load?

How did you mount yours? Please post pics.

The bolts are not in shear, but even if they were they could handle the load - 6 X 3/8- Grade 8 (each side). I'm also distributing the load to the middle of the frame using air springs. The resultant load on each front mount may be as low as 1klb. I'm using aluminum for construction and targeting a "light weight" camper.

Michel's rig is not mine. His attachments were in pure shear and were not properly engineered.

haven said:I'm concerned about your body mounts. It appears that they are bolted onto the sides of the frame rails in a manner that carries the weight of the camper on the bolts that pass horizontally through the body mount and the frame.

The Mitsubishi body builders guide says the weight of the camper sub-frame should rest on top of the truck chassis. The bolts should position the sub-frame on the chassis, but not be the major load-bearing element

The company that built Michel Szulc Krzyzanowski's Fuso camper used the bolts are the weight bearing element. The bolts failed after relatively few miles.

I hope I'm mis-interpreting your photos!

Chip Haven

Bajaroad

Adventurer

mcgovski said:Doesnt look like you are pretending to me! Nice work. Keep the pics coming!

Question: Are you going to have a portal through from cab to living space?

Looks awesome

Thanks.

Yes on the portal, but it's not yet on the radar.

subframe attachment

Brent,

Here's how I read the information in the Mitsubishi Body Builders Guide.

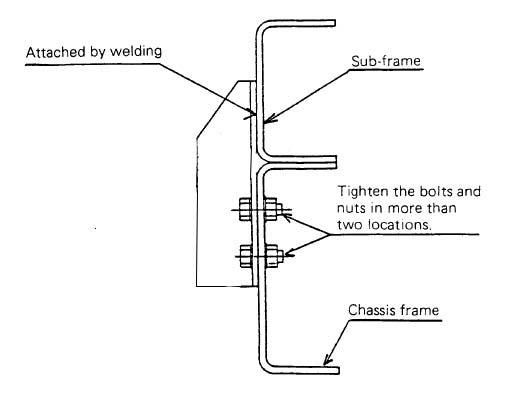

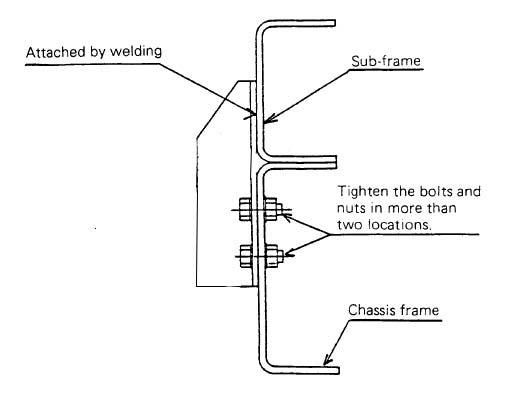

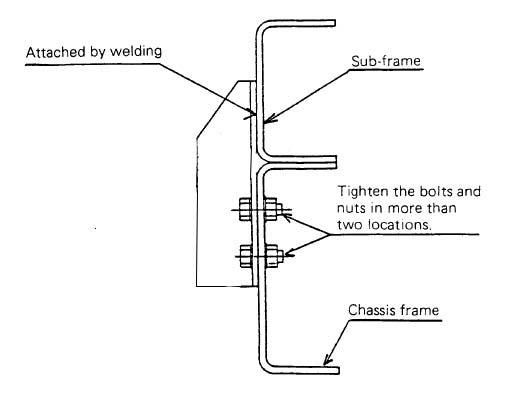

Figure 3.1 refers to a bracket that supports an accessory like a second battery or a gas tank. The weight of the accessory attached to the bracket exerts force on the threads of the bolt. That's why the bolts are described as under tension.

Figure 3.2 shows how you're supposed to attach the subframe that supports the truck body. Here most of the weight of the subframe is resting on the truck chassis. But some weight is carried on the shaft of the bolt, creating a shearing force.

Section 4.4 of the Body Builders Guide says that if you can't use U-bolts to hold the subframe to the truck chassis, then you're supposed to use a setup like Figure 3.2.

I hope you're correct that enough of the weight of the camper subframe will be carried by other points of attachment, making the Grade 8 bolts strong enough to carry the rest of the load. I suggest closely monitoring the bolts to see if they are starting to score or bend.

Chip Haven

Brent,

Here's how I read the information in the Mitsubishi Body Builders Guide.

Figure 3.1 refers to a bracket that supports an accessory like a second battery or a gas tank. The weight of the accessory attached to the bracket exerts force on the threads of the bolt. That's why the bolts are described as under tension.

Figure 3.2 shows how you're supposed to attach the subframe that supports the truck body. Here most of the weight of the subframe is resting on the truck chassis. But some weight is carried on the shaft of the bolt, creating a shearing force.

Section 4.4 of the Body Builders Guide says that if you can't use U-bolts to hold the subframe to the truck chassis, then you're supposed to use a setup like Figure 3.2.

I hope you're correct that enough of the weight of the camper subframe will be carried by other points of attachment, making the Grade 8 bolts strong enough to carry the rest of the load. I suggest closely monitoring the bolts to see if they are starting to score or bend.

Chip Haven

Bajaroad

Adventurer

Bolts are about 60% as strong in shear as in tension. Grade 8 bolts have a minimum tensile strength of 150KPSI (proof load @ 120KPSI). This is up to 4-5X stronger than no-grade bolts. Using the proof load, each 3/8in bolt can handle about 8000lbs (assuming cross section of major diameter). I'm using 6 bolts per side = 48,000lbs - it's difficult to see in the pics. Granted, the bolts and holes would have to line up perfectly to take a pure shear of 48000lbs, but they will easily take the weight of my camper in pure shear. And for the bolts to take a pure shear load they would have to be only hand tight to barely snug.

The thing is, most of the load is taken by the clamping force (friction) of the mounting backet to the frame. The bolts must be tightened correctly to acheive this clamping force. If each bolt is tighted (in tension) to 5000lbs, about half their rating, there would be about 30,000lbs of clamping/friction force - again each side.

There is additional clamping forces because the mounts are extended out from the frame, instead of directly over the mounting bolts. This creates a moment and places the bolts in additional tension - that's why the Fuso manual calls that setup "bolts in tension."

By the way, jet airplane rivets are design in pure shear. There is some clamping force but their rating assumes only shear. The point is, shear is fine it just has to be designed correctly.

Lastly, and maybe most clear, I'll bet all the key attachments are designed in a similar way - bolted to the side of the frame. Attached is a picture of the rear leaf springs - look familar - 6 bolts attached to the side of the frame. I bet the engine is also attached in a similar way.

The thing is, most of the load is taken by the clamping force (friction) of the mounting backet to the frame. The bolts must be tightened correctly to acheive this clamping force. If each bolt is tighted (in tension) to 5000lbs, about half their rating, there would be about 30,000lbs of clamping/friction force - again each side.

There is additional clamping forces because the mounts are extended out from the frame, instead of directly over the mounting bolts. This creates a moment and places the bolts in additional tension - that's why the Fuso manual calls that setup "bolts in tension."

By the way, jet airplane rivets are design in pure shear. There is some clamping force but their rating assumes only shear. The point is, shear is fine it just has to be designed correctly.

Lastly, and maybe most clear, I'll bet all the key attachments are designed in a similar way - bolted to the side of the frame. Attached is a picture of the rear leaf springs - look familar - 6 bolts attached to the side of the frame. I bet the engine is also attached in a similar way.

haven said:Brent,

Here's how I read the information in the Mitsubishi Body Builders Guide.

Figure 3.1 refers to a bracket that supports an accessory like a second battery or a gas tank. The weight of the accessory attached to the bracket exerts force on the threads of the bolt. That's why the bolts are described as under tension.

Figure 3.2 shows how you're supposed to attach the subframe that supports the truck body. Here most of the weight of the subframe is resting on the truck chassis. But some weight is carried on the shaft of the bolt, creating a shearing force.

Section 4.4 of the Body Builders Guide says that if you can't use U-bolts to hold the subframe to the truck chassis, then you're supposed to use a setup like Figure 3.2.

I hope you're correct that enough of the weight of the camper subframe will be carried by other points of attachment, making the Grade 8 bolts strong enough to carry the rest of the load. I suggest closely monitoring the bolts to see if they are starting to score or bend.

Chip Haven

ntsqd

Heretic Car Camper

Brent, I gather that you have already or plan to torque those bolts? I don't discount the value of friction induced by a torqued bolt pattern. Flywheels in general would never stay on if it were strictly up to bolt shear. I do worry (my GF says I do that too much) about bolt quality since there is no on-going QA done by SAE to insure that a bolt marked G8 actually conforms to G8 standards, and about long term loss of torque due to stretch. Consider possibly going to F911 hex bolts instead?

What about adding a structural tab to those brackets that sits on top of the frame rail? Sort of a "belt and suspenders" approach. Should the undesireable happen and those bolts were to fail in some way that mount wouldn't drop down & tweak the box.

On a much smaller scale (bicycle trailer) I worked out thin walled structural aluminum vs. steel in a strength vs. weight comparo and steel won. Had bicycle wall thickness' been easily available to me the results might have been different.

In any event I'm interested in following how this build goes.

What about adding a structural tab to those brackets that sits on top of the frame rail? Sort of a "belt and suspenders" approach. Should the undesireable happen and those bolts were to fail in some way that mount wouldn't drop down & tweak the box.

On a much smaller scale (bicycle trailer) I worked out thin walled structural aluminum vs. steel in a strength vs. weight comparo and steel won. Had bicycle wall thickness' been easily available to me the results might have been different.

In any event I'm interested in following how this build goes.

Bajaroad

Adventurer

Thanks for the interest . . .

As for higher quality bolts, if I was close to the design limits then I would consider stronger/higher-quality bolts, but I'm not close. My entire camper should only weigh 5000lbs. One bolt could hold it in shear. I have 12 in the front, most of the weight will be in the rear, and I'll have air springs taking about 1000lbs in the middle - mainly to reduce vibration and distribute the load on the frame. I'm thinking of also filling my tubes with He to lighten the camper further.

If I understand you correctly, you couldn't find an aluminum tube with an optimal wall thickness to compete with the steel. If I could find 4130 steel in thin wall rectangular tubing, then I would have chosen 4130. But low carbon steel isn't much stronger than 6061-T6 aluminum and it weighs 3X as much. Lb for Lb aluminum is stronger. The downside with aluminum is it loses a lot of strength in the weld zone - I designed my subframe based on the strength of dead soft 6061.

I was considering custom rectagular titanium tubing, but then the alarm went off and I had to get up and go to work .

.

As for higher quality bolts, if I was close to the design limits then I would consider stronger/higher-quality bolts, but I'm not close. My entire camper should only weigh 5000lbs. One bolt could hold it in shear. I have 12 in the front, most of the weight will be in the rear, and I'll have air springs taking about 1000lbs in the middle - mainly to reduce vibration and distribute the load on the frame. I'm thinking of also filling my tubes with He to lighten the camper further.

If I understand you correctly, you couldn't find an aluminum tube with an optimal wall thickness to compete with the steel. If I could find 4130 steel in thin wall rectangular tubing, then I would have chosen 4130. But low carbon steel isn't much stronger than 6061-T6 aluminum and it weighs 3X as much. Lb for Lb aluminum is stronger. The downside with aluminum is it loses a lot of strength in the weld zone - I designed my subframe based on the strength of dead soft 6061.

I was considering custom rectagular titanium tubing, but then the alarm went off and I had to get up and go to work

ntsqd said:Brent, I gather that you have already or plan to torque those bolts? I don't discount the value of friction induced by a torqued bolt pattern. Flywheels in general would never stay on if it were strictly up to bolt shear. I do worry (my GF says I do that too much) about bolt quality since there is no on-going QA done by SAE to insure that a bolt marked G8 actually conforms to G8 standards, and about long term loss of torque due to stretch. Consider possibly going to F911 hex bolts instead?

What about adding a structural tab to those brackets that sits on top of the frame rail? Sort of a "belt and suspenders" approach. Should the undesireable happen and those bolts were to fail in some way that mount wouldn't drop down & tweak the box.

On a much smaller scale (bicycle trailer) I worked out thin walled structural aluminum vs. steel in a strength vs. weight comparo and steel won. Had bicycle wall thickness' been easily available to me the results might have been different.

In any event I'm interested in following how this build goes.

ntsqd

Heretic Car Camper

On the bike trailer project it was more an "I" problem. I couldn't go large enough for the required stiffness without a massive increase in weight from the unecessary extra wall thickness. As it ended up the bare steel frame weighed 11 lbs and could carry one ~125 lbs female (6-7X the design load) w/o going into plastic deformation.

Ti weldments would make such a large structure hideously spendy and awkward to build. shudder.....

I was thinking of the high quality hardware more for consistant QA than YTS/UTS considerations.

Ti weldments would make such a large structure hideously spendy and awkward to build. shudder.....

I was thinking of the high quality hardware more for consistant QA than YTS/UTS considerations.

Bajaroad

Adventurer

FUSO 4X4 Testing

I got out to test the latest updates before heading off to the true test on White Rim and Moab. So far so good.

By the way, the air springs in the back help support the subframe while there is no camper box to add rigidity. The air springs will be joined by a common air line so that the pressure equalizes between the two volumes no matter what angle and corresponding compression/extension. This maintains a balanced upward force independant of the truck frame flex.

I will also be adding two airsprings to the middle of subframe to dampen vibration and further support the load.

I got out to test the latest updates before heading off to the true test on White Rim and Moab. So far so good.

By the way, the air springs in the back help support the subframe while there is no camper box to add rigidity. The air springs will be joined by a common air line so that the pressure equalizes between the two volumes no matter what angle and corresponding compression/extension. This maintains a balanced upward force independant of the truck frame flex.

I will also be adding two airsprings to the middle of subframe to dampen vibration and further support the load.

adrenaline503

Explorer

I don't know about the engineering side, but it sure looks cool.

dhackney

Expedition Leader

Brent,

Great work.

Excellent choice in using the T6 early and often.

RE: bolt quality

We had some G8 bolts break on our frame extension section during alpha testing. We switched to a different brand and replaced all of them. No problems there so far.

I just had a G8 bolt break on a water tank bracket a few days ago on Ruta 40. I don't know if it was random, but it does happen. Good to see you are over-engineering in that area.

Kudos on the build.

Wish I would have thought about the He idea. But I would have needed tube volume equal to the Hindenberg...

Doug

Great work.

Excellent choice in using the T6 early and often.

RE: bolt quality

We had some G8 bolts break on our frame extension section during alpha testing. We switched to a different brand and replaced all of them. No problems there so far.

I just had a G8 bolt break on a water tank bracket a few days ago on Ruta 40. I don't know if it was random, but it does happen. Good to see you are over-engineering in that area.

Kudos on the build.

Wish I would have thought about the He idea. But I would have needed tube volume equal to the Hindenberg...

Doug

ntsqd

Heretic Car Camper

FWIW when I was in the High Vacuum Industry we used He to leak test our chambers. He would go right past an O-ring seal or a TIG weld in 316 Stainless in a large enough volume that a mass spectrometer could identify it. That's not alot, but sealing would be a large issue.

Bajaroad

Adventurer

Helium

Though it would save some weight, the helium comment was intended as a joke - d'oh.

Though it would save some weight, the helium comment was intended as a joke - d'oh.

ntsqd said:FWIW when I was in the High Vacuum Industry we used He to leak test our chambers. He would go right past an O-ring seal or a TIG weld in 316 Stainless in a large enough volume that a mass spectrometer could identify it. That's not alot, but sealing would be a large issue.

Similar threads

- Replies

- 27

- Views

- 1K

- Replies

- 25

- Views

- 2K

- Replies

- 26

- Views

- 4K

- Replies

- 28

- Views

- 7K