I'd been investigating something similar from motion control, as well as uhmw polyethyelene based guides from 80/20 and a few others. Wondering how it seems to you from a binding standpoint? Probably way less of an issue with CNC precision and dead square installation as in your build. Curious how much slop/movement is present in the carriage bearing unit?

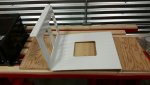

Was looking for something to control side to side motion and center my box as it articulated. My walls have some flex and wanted to find something to set the distance between the walls and keep it constant. Been using sliders, but they arent great for that, so I'm interested in a track and bearing carriage or uhmw based carriage for a couple reasons.

The track and carrier have very little to no slop, they are adjustable to compensate for wear, I adjusted mine so there is a little drag. They are strong, with something beefy enough they could take some flex out of the walls and that could set the distance, a UHMW slide would probably give less headache when dust or dirt is present. You are talking about replacing the slides between your top half and bottom half right? The system I designed does have a few features to allow for some movement, the HC core panels have some torsional flex ie you can "twist" them a bit which is beneficial, the extrusions are designed to allow for some of that flex so the camper is not a complete absolutely rigid box. The flex isn't that much, but more than what the chassis/deck flexes so the possibility of binding is small but exists. The biggest thing with the bunk is the platform floats, it just sits in the brackets, in case we aren't sitting perfectly level there will be no stress on anything, and the wall or shower wall will not even come close to having enough twist to affect the front or rear assemblies. I suppose I could fix it at one end, but I can pull it out in 2 seconds the way it is.