Get your tickets to THE BIG THING 2026!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Front bumper build. Step by step guide...

- Thread starter boo471

- Start date

Wh1t3nukle

I gotz dis

You should be done already now that you have a helper!!! hahahah Nicely done.

boo471

Adventurer

Hoops added

I did some work on the bumper yesterday. I was mainly focusing at getting the hoops mounted and starting to look at the internal reinforcements of the bumper.

I wasn't sure about using hoops at first but once I got them on i was very happy with it and thought it look pretty cool actually. It kind of makes the bumper a lot more aggressive.

Added the main center hoop to the bumper. It has about 30 degrees lean forward and is wide enough to house my 2 9" HIDs.

After that I started to play around with the head light hoops. Trying to find a good balance of protection and lean inboards/down to get that aggressive look. Once I had them where I wanted then I started doing the notching, by hand of course

I welded on tabs for my lights and test fitted them. Looks like one damn aggressive Baja racer in the front now

I also welded on some grid plating(or what ever you call it in English) to cover the vent holes so no big rock and other crap will fly in and hit my radiator.

Here is my "winch" in its position so I can start looking at a winch mounting plate and where to mount a cross member. I noticed that I wasn't able to move it as far to the side as I want to after I rounded the edges so the fairlead might not get perfectly centered.

This Is what it looked like at the end of the evening.

I hope I will be able to build some this weekend and hopefully get the reinforcements done so I can start welding everything and get this sucker done soon. I have a busted shoulder and spending this many hours every other evening building a heavy bumper like this is not really helping out

I did some work on the bumper yesterday. I was mainly focusing at getting the hoops mounted and starting to look at the internal reinforcements of the bumper.

I wasn't sure about using hoops at first but once I got them on i was very happy with it and thought it look pretty cool actually. It kind of makes the bumper a lot more aggressive.

Added the main center hoop to the bumper. It has about 30 degrees lean forward and is wide enough to house my 2 9" HIDs.

After that I started to play around with the head light hoops. Trying to find a good balance of protection and lean inboards/down to get that aggressive look. Once I had them where I wanted then I started doing the notching, by hand of course

I welded on tabs for my lights and test fitted them. Looks like one damn aggressive Baja racer in the front now

I also welded on some grid plating(or what ever you call it in English) to cover the vent holes so no big rock and other crap will fly in and hit my radiator.

Here is my "winch" in its position so I can start looking at a winch mounting plate and where to mount a cross member. I noticed that I wasn't able to move it as far to the side as I want to after I rounded the edges so the fairlead might not get perfectly centered.

This Is what it looked like at the end of the evening.

I hope I will be able to build some this weekend and hopefully get the reinforcements done so I can start welding everything and get this sucker done soon. I have a busted shoulder and spending this many hours every other evening building a heavy bumper like this is not really helping out

Last edited:

boo471

Adventurer

Looking Great! but can you put the light tabs on the inside? I know those lights are really deep.

I have the 7" version, you will be happy, they are bright.

That was my plan but then I cant open/close the hood.

Yeah I tried them on the back yard and they throw out some serious light.

java

Expedition Leader

That was my plan but then I cant open/close the hood.

Yeah I tried them on the back yard and they throw out some serious light.

Yeah I was having the same issue. I was able to turn the mount 90 degrees and have the tabs vertically. Might be an option, but mine still just touch the hood when opening.

boo471

Adventurer

Looks great dude! Having just built a rear swing-out bumper by hand using fluxcore, I can totally relate to what you have been up to, however your design is way more ambitious. Looking forward to seeing the finished results.

Thanks. Well if your going to do it. Do it dirty. Flux core is a little ruff but it works.

Nice bumper build by the way. Looked really good!

Sent from my iPhone using Tapatalk - now Free

Wh1t3nukle

I gotz dis

Coming along just gravy buddy. That grid stuff is typically called "expanded metal".

I like the lights and I don't see any cooling issues with them like that. kudos

I like the lights and I don't see any cooling issues with them like that. kudos

I did some work on the bumper yesterday. I was mainly focusing at getting the hoops mounted and starting to look at the internal reinforcements of the bumper.

I wasn't sure about using hoops at first but once I got them on i was very happy with it and thought it look pretty cool actually. It kind of makes the bumper a lot more aggressive.

Added the main center hoop to the bumper. It has about 30 degrees lean forward and is wide enough to house my 2 9" HIDs.

After that I started to play around with the head light hoops. Trying to find a good balance of protection and lean inboards/down to get that aggressive look. Once I had them where I wanted then I started doing the notching, by hand of course

I welded on tabs for my lights and test fitted them. Looks like one damn aggressive Baja racer in the front now

I also welded on some grid plating(or what ever you call it in English) to cover the vent holes so no big rock and other crap will fly in and hit my radiator.

Here is my "winch" in its position so I can start looking at a winch mounting plate and where to mount a cross member. I noticed that I wasn't able to move it as far to the side as I want to after I rounded the edges so the fairlead might not get perfectly centered.

This Is what it looked like at the end of the evening.

I hope I will be able to build some this weekend and hopefully get the reinforcements done so I can start welding everything and get this sucker done soon. I have a busted shoulder and spending this many hours every other evening building a heavy bumper like this is not really helping out

boo471

Adventurer

Front bumper build continues...

This weekend was spent working on the bumper. There was a lot of progress on it. I added the reinforcements needed. I also added a cross member, Winch plate and boxed in the area holding the winch plate and mounting plate.

I also welded all the welds on the entire bumper. Full welds on the outside of the bumper and seems on the inside since I will smooth out the outside of the bumper and remove some material I wanted more welds on the inside as well.

Surprisingly there was very little warping. This is a benefit with using smaller pieces and lots of triangles in your design. It makes it VERY strong.

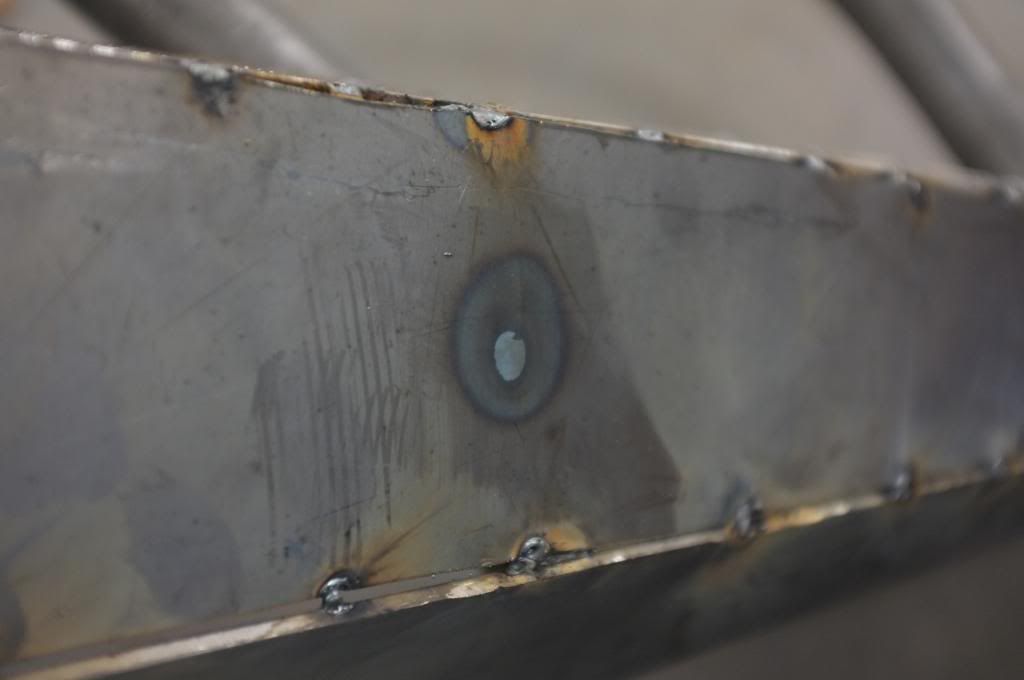

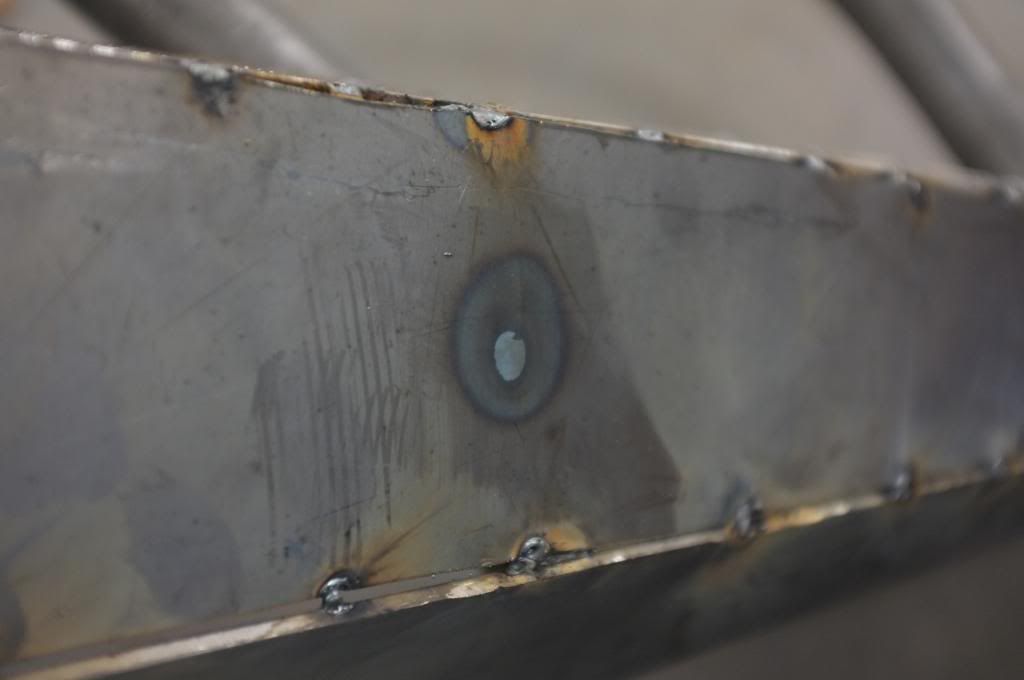

I started with adding reinforcement plates to the "wings"

Good penetration for a cheap welder and using no gas.

Then I added the cross member and started working on the boxed in section which will strengthen up the entire area around the mounting plate and winch plate.

Prepped with welds before adding parts (I wont be able to weld here after adding the parts boxing in this area.

Started boxing in

Added the winch plate. In the end I did 3 runs on all welds holding the winch plate.

Continued boxing in

Then I started welding all the welds on the outside. Started with the tubes.

and then just work my way from side to side to keep the warping in check. You have to be careful about where to weld here to not get a completely crooked bumper.

At the end of the weekend it looked something like this. It took my about 5hrs to weld everything.

I added another tab as you can see on the passenger side tube. This will hold my CB antenna.

Now I have a a few fun hours of grinding to do to make the outside of the bumper smooth and seamless.

To be continued.

This weekend was spent working on the bumper. There was a lot of progress on it. I added the reinforcements needed. I also added a cross member, Winch plate and boxed in the area holding the winch plate and mounting plate.

I also welded all the welds on the entire bumper. Full welds on the outside of the bumper and seems on the inside since I will smooth out the outside of the bumper and remove some material I wanted more welds on the inside as well.

Surprisingly there was very little warping. This is a benefit with using smaller pieces and lots of triangles in your design. It makes it VERY strong.

I started with adding reinforcement plates to the "wings"

Good penetration for a cheap welder and using no gas.

Then I added the cross member and started working on the boxed in section which will strengthen up the entire area around the mounting plate and winch plate.

Prepped with welds before adding parts (I wont be able to weld here after adding the parts boxing in this area.

Started boxing in

Added the winch plate. In the end I did 3 runs on all welds holding the winch plate.

Continued boxing in

Then I started welding all the welds on the outside. Started with the tubes.

and then just work my way from side to side to keep the warping in check. You have to be careful about where to weld here to not get a completely crooked bumper.

At the end of the weekend it looked something like this. It took my about 5hrs to weld everything.

I added another tab as you can see on the passenger side tube. This will hold my CB antenna.

Now I have a a few fun hours of grinding to do to make the outside of the bumper smooth and seamless.

To be continued.

boo471

Adventurer

Coming along just gravy buddy. That grid stuff is typically called "expanded metal".

I like the lights and I don't see any cooling issues with them like that. kudos

Expanded metal. Ok good to know. Being a Swede some of the English words don't come natural to you. I dont think I even know what this is called in Swedish

Yeah I think I will be good with the lights. Probably no problems there.

//Marten

boo471

Adventurer

Wow! Very nice. Seeing the step by step process really makes you appreciate all the time and effort required. And makes the high price tag of arb tjm etc seem a bit more reasonable!

Thanks! Well most of the manufacturers will use laser/water cutting. Jigs and might even use robots to weld. So that will will lower the cost for manpower massively.

I only have a few hundred in materials in it but I have a lot of hours in it.

If I did a second one it will probably be a lot shorter since I have kept all the templates. And now know the design.

Sent from my iPhone using Tapatalk - now Free

Similar threads

- Replies

- 2

- Views

- 253

- Replies

- 0

- Views

- 257

- Replies

- 0

- Views

- 136

- Replies

- 1

- Views

- 601