I will admit, that is one of the better winch cables I have seen in a while, especially one 18 years old. Good job on taking such good care of it

I do still see the memory factor with it stretched out on the ground, it only gets worse on the tighter layers on the drum in my experience. I also see lots of small broken strands...I wouldn't be going anywhere near it without gloves for handling it, sorry. I've been bitten to many times.

This is more typical of what I see for steel cable and was pulled off the used 8274 that was rebuilt on my LX45 ( which also has synthetic now ). If you look close there are a few flat spots, kinks, loops, and broken strands. This cable was about the same vintage as yours I believe, but I don't know all the history. It has been sitting on the old trailer for a few years now. I am surprised it doesn't show more signs of surface rust. I wonder if it is galvanized?

This is what it looks like with all the rope off the drum on the good ol' flatty. These upright winches hold a lot, and I usually under-fill them a bit for better performance and off-angle pulling. Note: It lays down FLAT tip to tail with zero memory under zero tension. This is one of the things that sold me on synthetic lines all those years ago. You can spool it off in a big clump at your feet and throw it up to the anchor location.

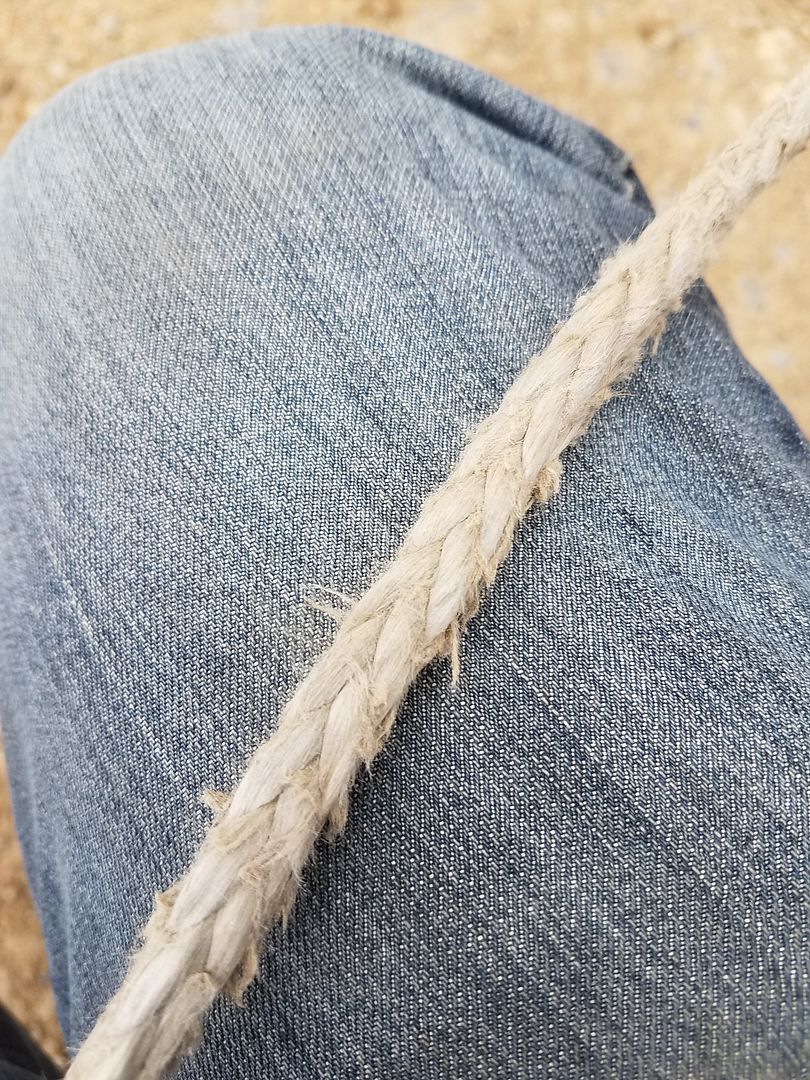

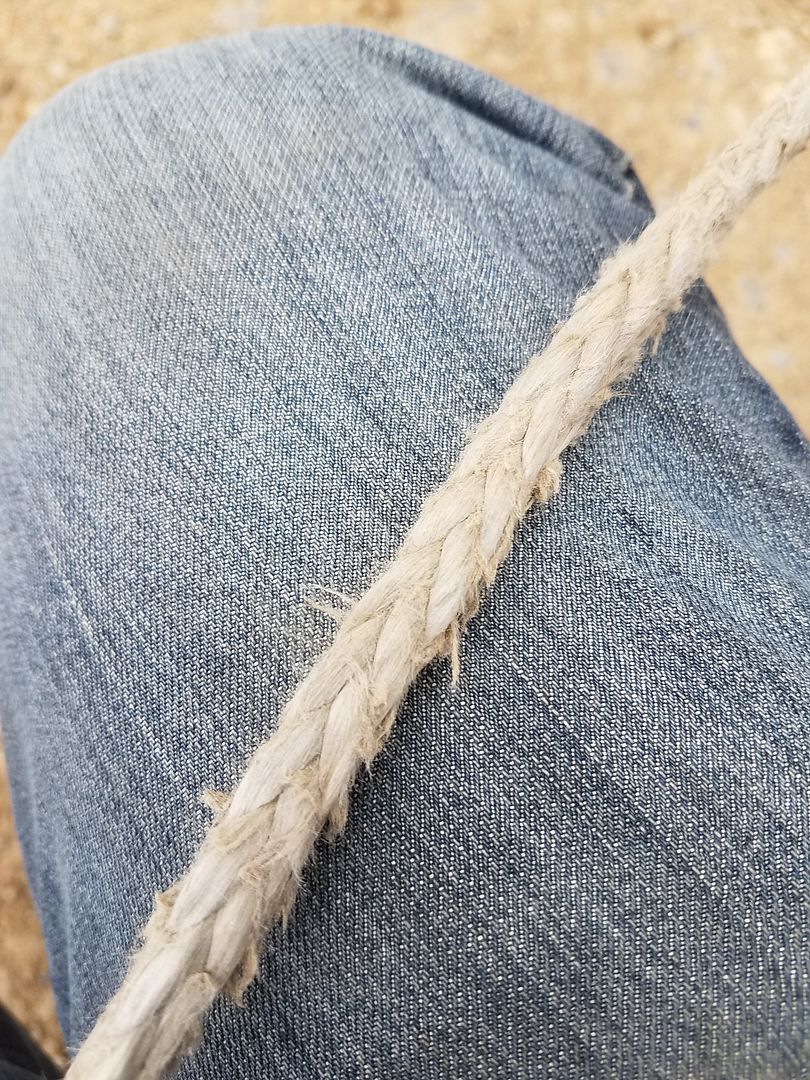

This is the worst spot I could find on the entire winch line. It was somewhere in the middle. Nothing to worry about with the rope being rated at a hair over 20K MBS in 10mm SK-75 Dyneema. I find most steel cable rated pretty low in comparison, 5/16 is only rated for an MBS of about 9900lbs. I do find that larger diameter synthetic lines are more durable in the long term. I've never broken one of my 10mm lines yet. I have been around a few 5/16" synthetic lines that have popped, and on inspection where found to have heat damage ( from a dragging in drum brake) . No...you can't pull synthetic lines over razor blades on fire, but in general I find most of the internet rumors about how fragile synthetic lines are to be hogwash in my experience. In my experience once the line develops the 'fuzz' texture it stops changing. Talking with our Sampson Rope guys at the office, that is normal and expected. The 'fuzz' generally functions as both a UV guard and an abrasion guard to protect the majority of the inner fibers which carry the load.

This section still looks new some 7+ years later. This rope has been flat out abused. I actually care for it less than I know I should because I want to see what the limits really are. It has never been washed once other than in the rain or snow when being used. It has been used in dirt, sand, rock, mud, and snow almost from coast to coast.

Here is the best picture I could come up with to show the most line at once. This is just about all the line top to bottom spooled off the drum. I'm actually surprised it looks this uniform in wear. I can't say that I always done a full pull or a short pull. I know I haven't throught about it much over the years. It has always worked well for me.