rnArmy

Adventurer

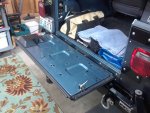

So I got a 3500lb axle the same width as was I had on there, but with electric brakes. Had to have the spring perches welded on, and then it was pretty much a bolt-on affair. Old and new pictured below.

Mini Harbor Freight (type) Trailer Ultimate Build-Up Thread - Page 172 - JeepForum.com

A couple things though...

1. I needed to rewire the trailer for the electric brakes, and rewire the Jeep for a brake controller. Not that big a deal; just a bit time consuming. I also used a junction box to make it easier (tucked up under there nicely), and if I ever wanted to make changes in the wiring I could. Now I also had a wire for if I wanted back-up lights, and a permanent hot wire in case I ever needed it (currently it is capped off).

So with a permanently hot wire, if I ever want to put a 12-volt accessory plug on the trailer, I can. If I want to put some camp lights on the trailer (or maybe some low energy draw LED perimeter lights to keep on all night) I can. Or if I got a 12-volt fridge for the trailer, I could run it. As long as the trailer is plugged into the tow vehicle, I've got constant 12-volt power.

2. I also purchased a spare hub with bearings (the brake drum is the hub).

3. If I knew then what I know now, I would have ordered a wider 3500lb axle the same time I was getting the 235 tires, so I could run rims with a bit more backspacing. It would keep the brake drums further inside the rims for protection. Oh well, I'll keep running what I've got.

I've been very happy with the electric brakes, especially when the trailer is being pulled by the TJ. They seem to help. And I can manually max out the brakes on the trailer via the brake controller if I need to. I've had no negatives by having the electric brakes. And the axle is much stronger, but doesn't look oversized on a small trailer like mine.

At around this time, we also put shocks on the trailer. Not that I really felt it needed them, but it was more of an exercise to see if I could make it work simply and inexpensively. I could.

I also put a rack on the lid for extra storage. Also worked out nicely. I thought it needed something.

We were getting the trailer ready for our next big trip - from Ft Hood TX up to northern Canada to run the Dempster Highway. Woo Hoo!!! Would there be any lessons learned on this trip? Stay tuned....

Mini Harbor Freight (type) Trailer Ultimate Build-Up Thread - Page 172 - JeepForum.com

A couple things though...

1. I needed to rewire the trailer for the electric brakes, and rewire the Jeep for a brake controller. Not that big a deal; just a bit time consuming. I also used a junction box to make it easier (tucked up under there nicely), and if I ever wanted to make changes in the wiring I could. Now I also had a wire for if I wanted back-up lights, and a permanent hot wire in case I ever needed it (currently it is capped off).

So with a permanently hot wire, if I ever want to put a 12-volt accessory plug on the trailer, I can. If I want to put some camp lights on the trailer (or maybe some low energy draw LED perimeter lights to keep on all night) I can. Or if I got a 12-volt fridge for the trailer, I could run it. As long as the trailer is plugged into the tow vehicle, I've got constant 12-volt power.

2. I also purchased a spare hub with bearings (the brake drum is the hub).

3. If I knew then what I know now, I would have ordered a wider 3500lb axle the same time I was getting the 235 tires, so I could run rims with a bit more backspacing. It would keep the brake drums further inside the rims for protection. Oh well, I'll keep running what I've got.

I've been very happy with the electric brakes, especially when the trailer is being pulled by the TJ. They seem to help. And I can manually max out the brakes on the trailer via the brake controller if I need to. I've had no negatives by having the electric brakes. And the axle is much stronger, but doesn't look oversized on a small trailer like mine.

At around this time, we also put shocks on the trailer. Not that I really felt it needed them, but it was more of an exercise to see if I could make it work simply and inexpensively. I could.

I also put a rack on the lid for extra storage. Also worked out nicely. I thought it needed something.

We were getting the trailer ready for our next big trip - from Ft Hood TX up to northern Canada to run the Dempster Highway. Woo Hoo!!! Would there be any lessons learned on this trip? Stay tuned....

Last edited: