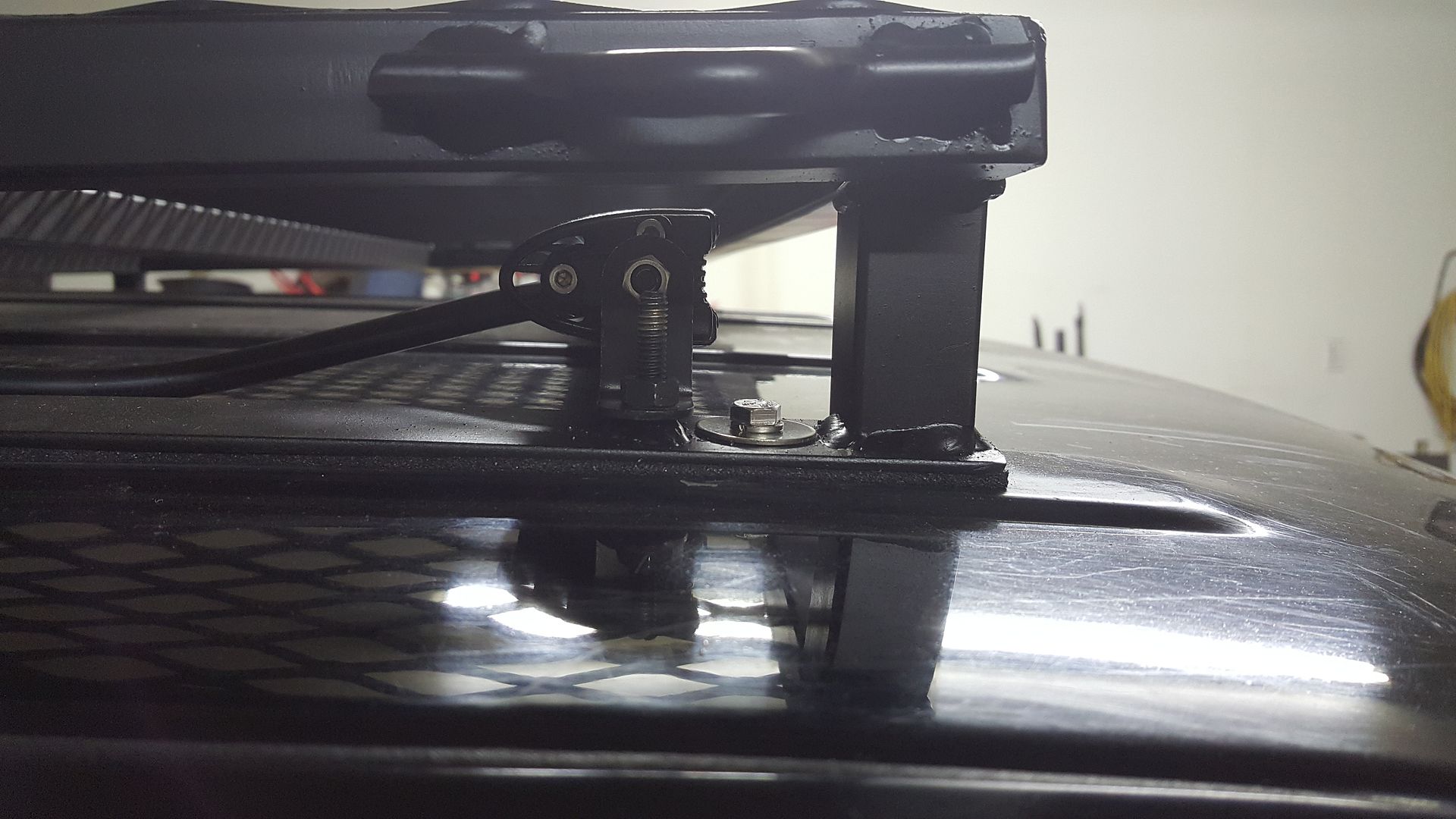

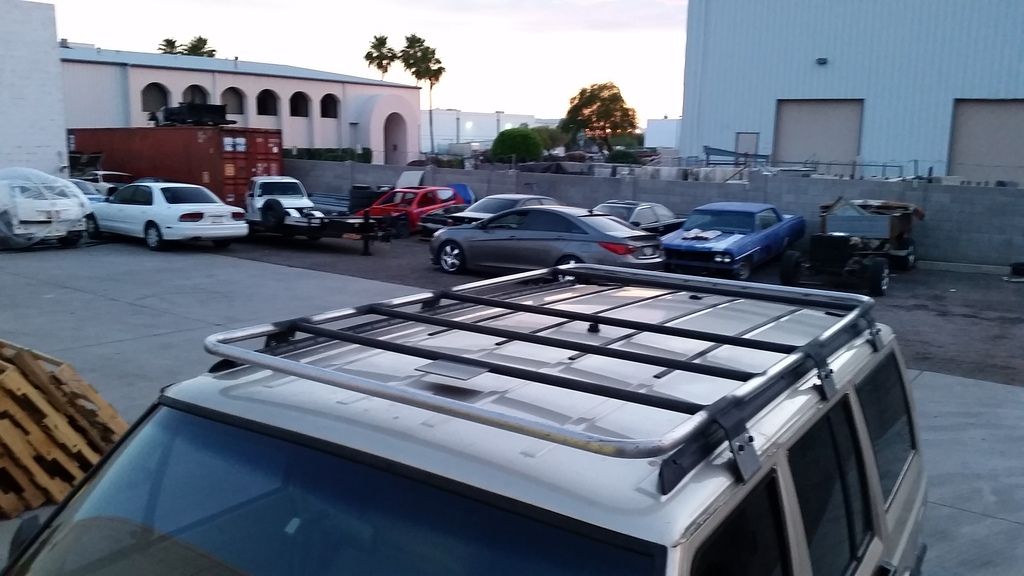

This is a cargo rack that I made out of 1/2 and 3/4" thin wall conduit. (EMT) Just get yourself a conduit bender and have at it. Plus a welder. I use gas welding which I like more than electric.

View attachment 259186View attachment 259187

I've looked through this whole thread (all 50+pages) more than 3 times! I've sketched out and worked up numerous designs in CAD and I haven't been able to settle upon anything yet. But ^^^ this ^^^ design... very nice - I thank you... this is most likely the inspiration I needed to get mine all figured out. I was going to use E-Track between 1" tubing but it would create large regions of un-level floor for the rack... but using uni-strut like this would allow you to get tie downs around individual items in the rack - thus avoiding having to unstrap lots of items just to get to a single item - plus it keeps things relatively level. THANKS!!!