rruff

Explorer

Where I live (7k ft, S NM) I think a black panel will go up to 200F, in calm sunny conditions and ~80F air temp. That was facing the sun mid-day. It's sunny today, maybe I'll check again.2) Some one asked if I had delam. There are about 5 small 2x3'ish patches that have experienced thermal delam. As the truck is parked in the sun the temp of the skin does go in the range of 150-175 deg. F. Any air pockets in the matrix will expand, lifting the skin ever so little.

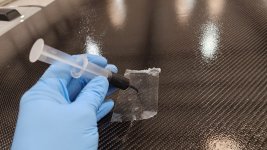

It is almost impossible to create a panel as I did, or outside a hydraulic or vacuum press to not have small voids. Specially when you are conscience of resin to fiber ratio's. I treat them as norm and part of the deal, so I will show you how to stop them in their tracks.

Some surfboard builders will perforate the skin with a roller that has a bunch of tiny needles, to let air escape. Foams outgas when they get hot; it isn't just trapped air, any place the bond is weak can delam.

When I experimented with XPS it was really hard to get a good bond. I tried sanding, and texturing with various devices. The one that worked the best was sand then clean then texture with a wallpaper perforation roller that makes a bunch of conical indentations. I'd put a layer of epoxy over that and work it into the indentations, and let that mostly cure, then add the layup. I decided to use PVC foam though which is a lot stronger and bonds better due to larger cells which give it a rough texture when cut.