ebrabaek

Adventurer

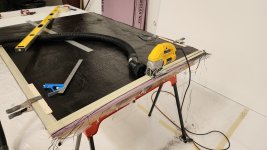

Time to break the mold. This is always so exiting as you truly dont know what ya have until you see it... Ha ha.

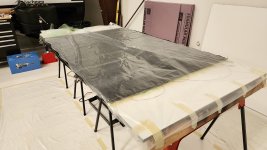

Top panel lifted....

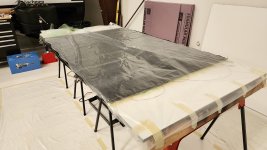

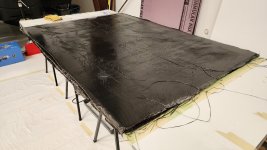

Plastic pealed back....

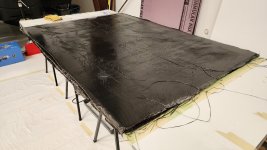

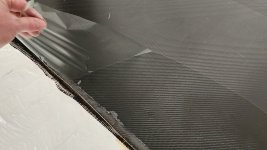

As afore mentioned you can get a smooth back side as well as the front side if you just treat the top panel with release agent. This looks a lot worse than it is. It will be on the inside..

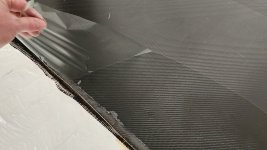

Flipped over..... a clean satin surface that will look awesome. Note the area bottom left where I had begun pealing the release agent film off.....

You just peal.......and peal some more.

And were done. There are still a bit that need to be cleaned but the most is off. Note all the film on the left hand side.

Top panel lifted....

Plastic pealed back....

As afore mentioned you can get a smooth back side as well as the front side if you just treat the top panel with release agent. This looks a lot worse than it is. It will be on the inside..

Flipped over..... a clean satin surface that will look awesome. Note the area bottom left where I had begun pealing the release agent film off.....

You just peal.......and peal some more.

And were done. There are still a bit that need to be cleaned but the most is off. Note all the film on the left hand side.