All to many times over the years of working with composites, I need to pivot. Sometimes it is my fault and sometimes it is just a simple mistake. You do these things long enough and it'll happen. Your success is not measure in how good the project looks in the end, but how you pivot, because as in so many instances that "failure" or "mistake" is here, front and center and now you have to deal with it. How you do that is when you really lean to think outside the box. In my case after cutting the top (roof) panel, I decided to change the angles of the sides outwards a bit due to a better look. Unfortunately that left about a 1.75 inch gap in the roof panel.....arrrrgggg...... Well Wilbur..... veeeee pivot nov.

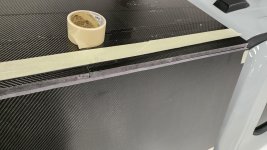

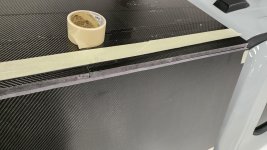

Had a few strips leftover. Simply bonded them to the "gapped section (forward) on the roof panel.... done. When you do that you can get a smooth seam by using shipping tape to hold the pieces together on the smooth side. This is on the roof. Only winged creatures and pilots will see the camper from that side,,, Ha ha ha. I apologize for not having pictures of that as when the pivot happens, things are kinda hectic and I am focused on that, not on taking pictures. I will do a recreated tutorial a bit later recreating the pivot.

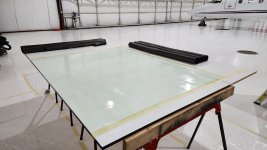

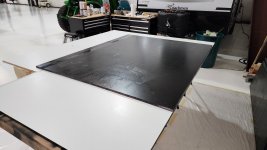

Panels cut with the gap showing.

"Gapped pieces cut ready for bonding"

First we measure......again..... the line of the roof.

We then trim that panel.....again....ha ha.... and ready ourself for the initial bonding

Now the pivot is behind us, lets bond the roof section to the rest of the box. Color pigment added to the Thixotropic...... and a small bead on the inner carbon flange.

Done. This will hold the pieces together, be as it may nowhere at full strength, but just enough to be able to take off the camper and set it down on the work bench for the rest of the journey.

Scraped the innder side of the edges with the bead of Thixotropic with a popsicle stick......yes they are good for other than holding frozen items....

Then added a bit of heat to keep about 75 deg. F. inside the box. Now curing.

Just want to again mention that if you desire a smooth surface on the inside (like the outside) just treat the top melamine covered particle board with release agent instead of a thin sheet of plastic. Both sides would be smooth. It is extra work which is not important to me at this project, but it might to others.