So there has been much debate as to the extensiveness of this refurbishment.

In evaluating the parts and pieces there is no doubt that this top was overloaded. The top was never designed to carry a lot of weight. Not to mention the fact that the weight was placed on the outer edges of the roof quite a way from the bearing points of the frame crossbars.

As I have mentioned previously, I don’t intend to put a lot of weight on top but the reality of it is, everything adds up.

As much as I want a walking foot industrial style sewing machine to modify and make alterations to the softwalls, I cant afford the time. I can see making my own alterations turning into a much bigger project. Like extending the soft walls over the cab for more top up interior space.

I also found that my softwalls are “convertible top material” so not really canvas but a heavy cloth backed vinyl. That led me to an upholstery shop. Where the vinyl now sits waiting for a potential match of the original material (unlikely, so black), replacement of the stained front lower panel, and a couple bungee ring loops that had degraded, all for $100ish

Meanwhile, I have been moving forward with the top itself. Speaking of debate, its tough laying out a roof.

I wanted the biggest single solar panel I could get under 200 watts. One of the main reasons being simplicity of attachment and not requiring a rack.

Highly recommended on other vanner forums, I found these “Hitech” brand solar panels on ebay. They are made in USA, and the ebay seller has great reviews.

I was looking at their 180w panel when I noticed this one,

https://www.ebay.com/itm/200-25-Watt-12-Volt-Solar-Panel-Off-Grid-RV-Boat-highest-power-12V-you-can-buy/264048386965?ssPageName=STRK%3AMEBIDX%3AIT&_trksid=p2060353.m2749.l2649

This is the 200watt bifacial panel. These cells see light on both sides. The back sheet is clear so any light that passes through the panel or comes in from the sides is harvested. Don’t get me wrong I think this will be a minor gain. But, it’s the same overall size (27x58, ish), and was only $5 more and came with z brackets I actually ended up using so….. will see how it goes, if it doesn't hurt performance....why not?

I also got a maxair fan for xmas! Santa knew I wanted the non remote 6200 because we would lose the remote, and I have also heard it needs direct line of sight. I plan to put a kill switch in my lower control panel so it can be shut off from the lower bed area without getting up.

I had also planned to put the fan in the center of the roof with the panel forward but the 58” length of the panel seemed to crowd the leading edge to much. Then I realized that with the center fan location I likely wouldn’t be able to access it with the top down which I think is dramatically underutilizing its usefulness. Its much different laying these things out without using the top before hand.

So I decided on putting the fan in front of the front push block. I will likely be able to control it from the drivers seat. I do have concerns about noise but ok with making a insulated cover/insert to help with that.

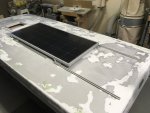

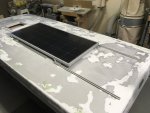

That puts the solar panel in the center. Again, much debate on how to attach. I wanted it as low profile/stealth as possible, yet modify-able for other/replacement panels in the future. I found some 80/20 15 series surface mount t-slot on ebay garage sale. I chose 3’ sections because the top isn’t completely flat, also shipping was cheaper on 4, 3’ sections. These accept ¼”-20 carriage bolts in the slot.

Mocked up it looks like this,

I went ahead and glued these down with Loctite PL marine.

The excess t-slot in the rear may be used for a small basket or maybe even just a aluminum plate with slots for straps (future additional solar panel?). Really I'm looking for a place to toss some branches/firewood when there is none available at a camp site specifically. I have found a need to do this and usually toss it all behind the front seat and it makes a mess. The only other thing I would consider putting up there is our two rolled up paddle boards, at 50 lbs. for the pair it might be more than I want to put up there with the top up for any length of time but it would be nice to not have them stuffed under the bed on road trips.

I picked up a new LED brake light to replace the non waterproof incandescent housing. Its size required some “tabbing” of the corners of the old hole with fiberglass tape. At the same time I filled the numerous holes in the top (like 22) with epoxy and faired them out. Some of the bigger holes required a fiberglass tape patch on the bottom before filling from the top.

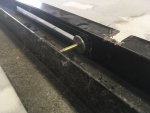

I also epoxied an aluminum backer where the front latches are.

Cut the hole for the fan with a jigsaw. You can see I changed my mind and moved it back a bit. I started thinking about the softwalls folding up in front of it.

I epoxied in Baltic birch backers that we pre-coated in penetrating epoxy. The opening got a strip of 4" fiberglass tape.

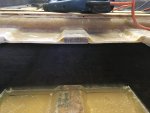

The core.

The new brake light even came with a test switch/battery.

More to come!