Drawer System Insert

I’ve been wanting to work with extruded aluminum since I stumbled upon the stuff on Amazon. I was considering a rebuild of

the Nomad’s drawer system to shed some weight and looked up aluminum framing and found all kinds of applications for 3D printers. I started to do my homework. After a few weeks of poking around the interweb I decided to start the drawer system insert build for the Tahoe.

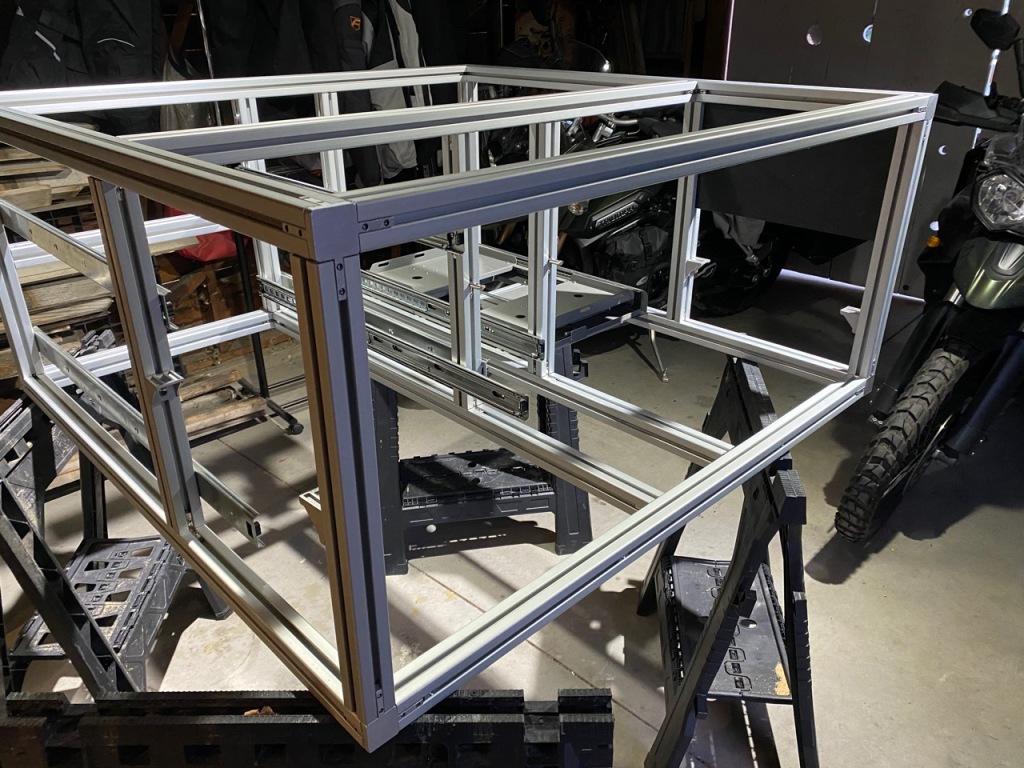

There are several different sizes of extruded aluminum (EA), 1010-10, 2020-20, 4040-40, and so on. I looked at a build using 2020-20 and wasn’t convinced of its rigidity and decided to go the 40 route, which is equal to one and a half inches. Once I selected the size, I checked out all the hardware I could find to put it all together, basically a big erector set; 3-way end corner brackets, T-nuts, L-shape interior corner connectors, and right angle corner brackets, the main supplier for most of which is

80/20. It’s a great place to start when thinking through your build.

For this build I wanted to up my game on appliances and design, while the Nomad’s drawer system met our needs, the Tahoe will be my last build and used much more than our travel needs required before, so I wanted this to be more convenient and user friendly. This meant a larger fridge/freezer with easier access and a two burner stove with an integrated sink, all on pull-out hardware that creates an overland kitchen out of the back of the Tahoe.

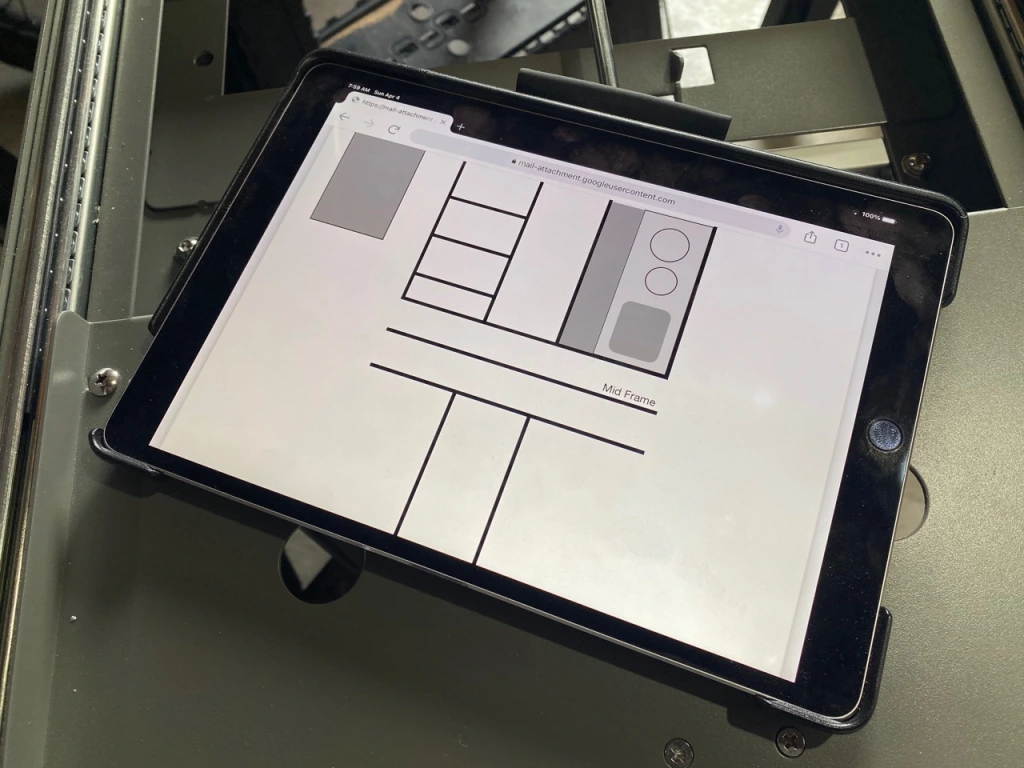

Storage is another upgrade with easier access along with a dog deck that is load-friendlier and roomier. I mocked up a digital design and started acquiring appliances and hardware.

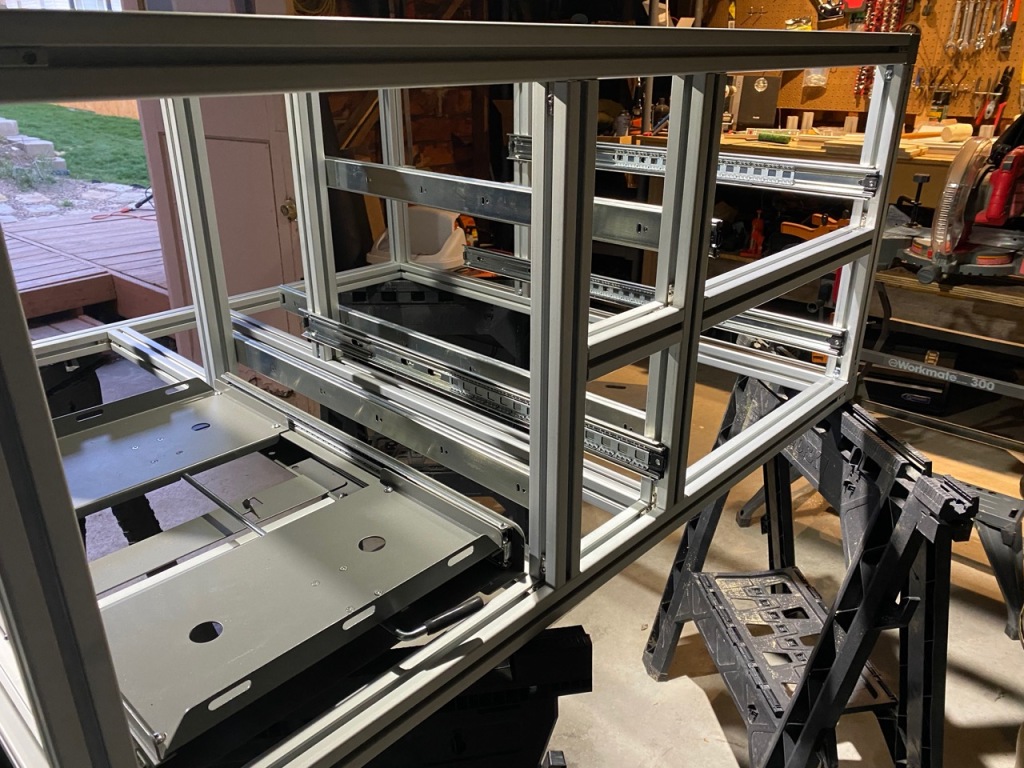

The bottom of the main frame was cut to spec and assembled inside the Tahoe to double-check fit and clearances. With that complete I bolted the fridge slide onto the three parallel crossmembers and started adding the uprights.

Planning steps ahead is crucial to working with EA, plotting the position of mounting locations, uprights, and the location and type of hardware needed to make connections and fasten the frame together. Once it’s built, it’s a pain in the ass to undo joints to add stuff. If you’re like me, you know plans are going to change, so it’s a good bad idea to not tighten everything down until it’s time to apply the LockTight.

I built the top frame to create a height inside the Tahoe to come up just to the rear window opening at 22 inches, making the entire insert 48Wx44Lx22H. After one last test fit, I moved on to creating the stove/sink pullout.

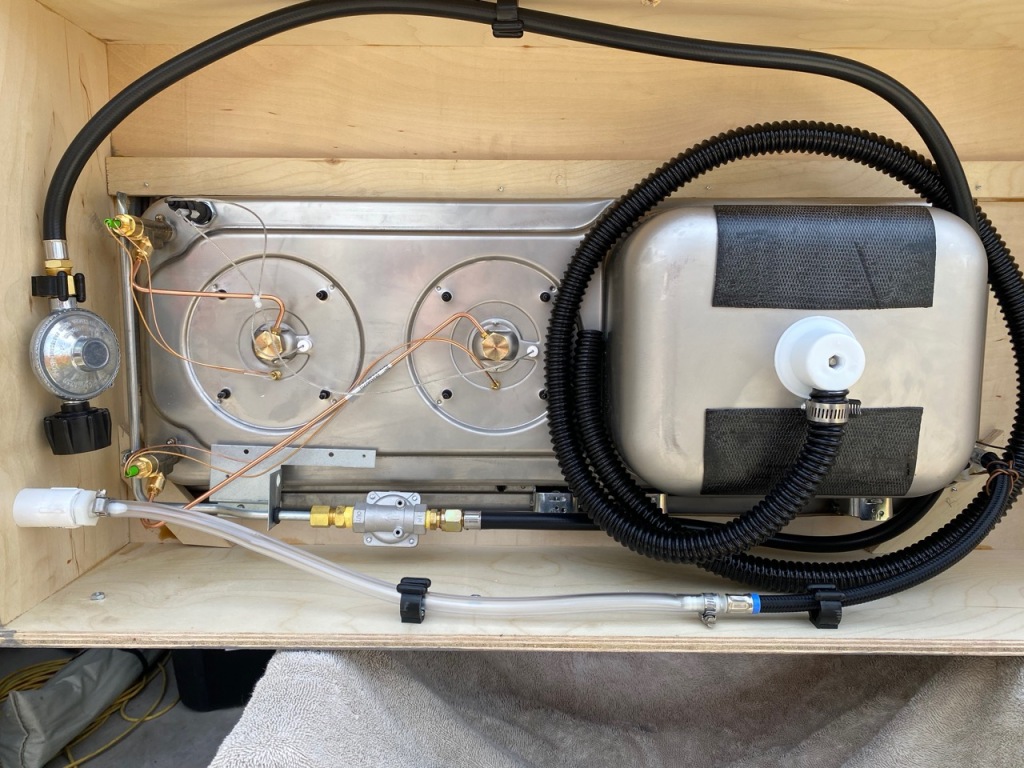

One plan change was creating a bit more of a work area around the stove/sink insert. That ate up some of the center drawer real estate, but I have a new plan for that as well. The insert is from Dometic, it’s the UK MO9722RUS Slim 2-Burner Hob/Sink Combination with Glass Lids. It’s a European application that was converted to US Lp gas. The unit appears to be no longer available. I had to order the faucet from a company in England (not yet pictured).

For the fridge I chose ICECO’s JP40 40 liter fridge/freezer coming in at 18″ tall, perfect what this application.

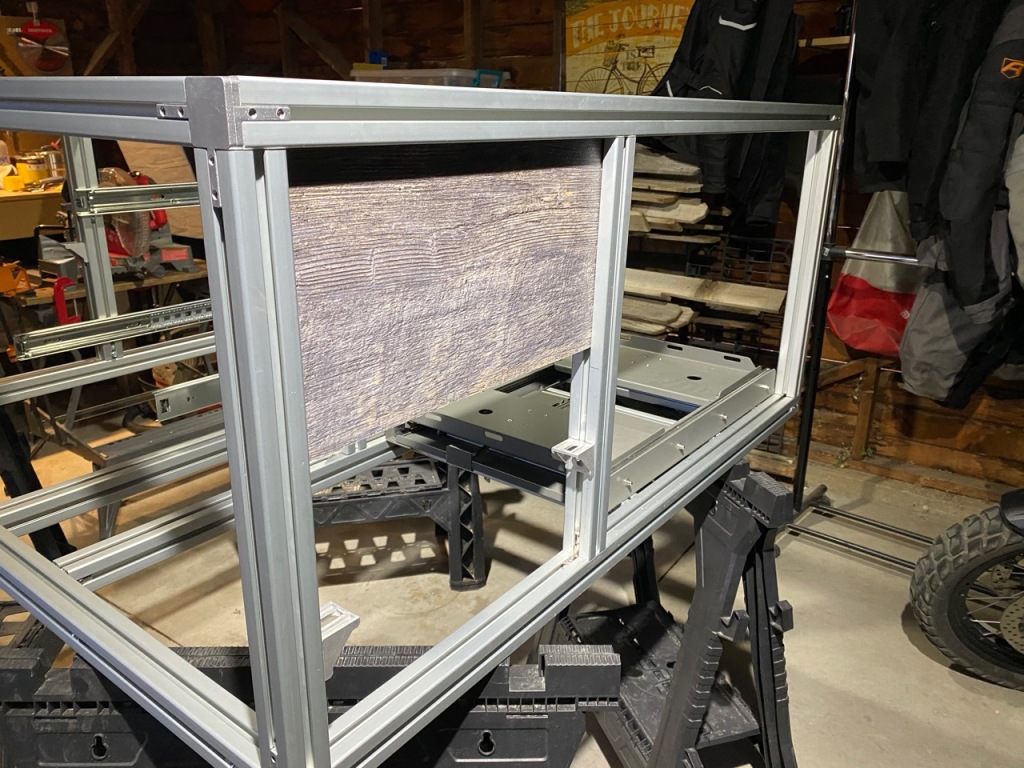

The stove/sink insert fits in the bottom RH side with a matching 30″ drawer above for cooking, serving and dining hardware. The outboard side (tailgate) is shown below.

I’m building a narrow 30″ two-level pantry drawer that will install into the middle section (omitting the horizontal cross member).

The original plan had a middle frame with horizontal EA to add support and places to install the drawer slides, but I omitted the mid frame as well deciding to use the slides as stressed members of the frame as well, keeping them height adjustable as well.

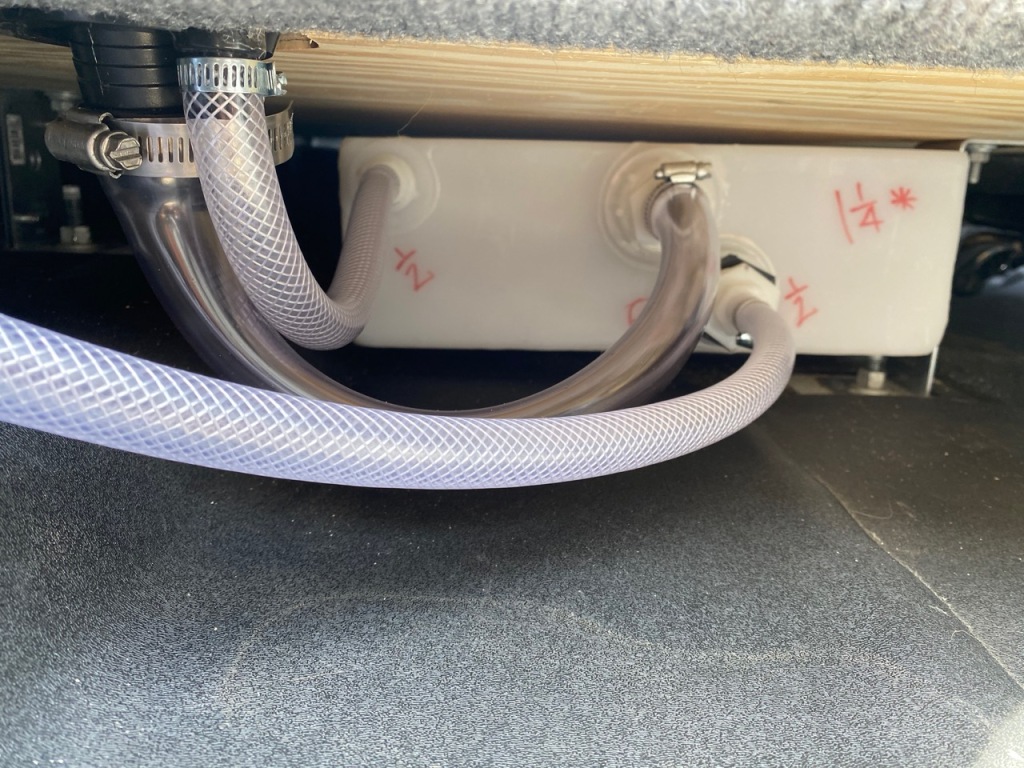

The inboard side of the insert will have a large storage compartment for camp gear with a vertical door that opens from the top, swinging down to

the dog deck.

This space will have two shelves and house the unit’s water pump. Speaking of which, with the spare tire relocation, the space underneath the rear of the Tahoe between the frames will be used to mount a 20 gallon water tank. The Lp gas for the stove will be sourced from a 5lb tank mounted to

the spare tire swingarm.

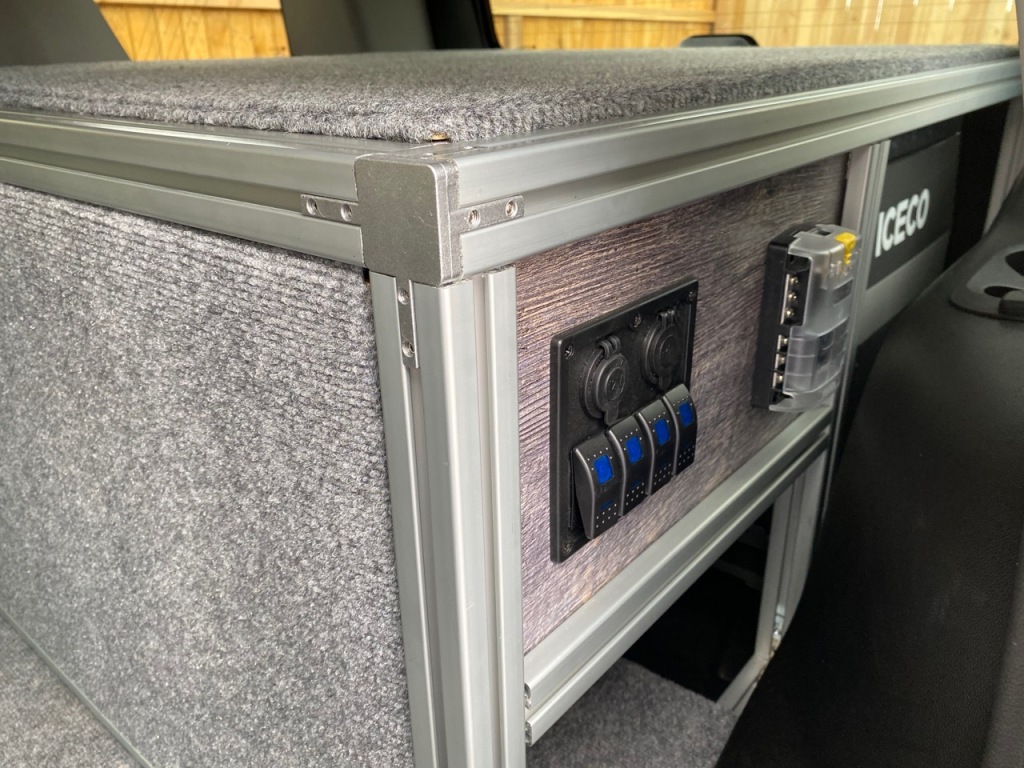

One last detail is the 12v system that will be mounted on this panel which will include a Blue Sea blade fuse block and a switch panel for power to the fridge, water pump, worklights and USB ports. Power is drawn from the Tahoe’s secondary stock house system. The system will be connected to a 100a fuse with a quickconnect to enable easy removal of the insert.

All the drawer and door facias will be finished with the same type of panel – leftover flooring from our home remodel – and there will be a panel covered in grey indoor/outdoor carpet on top providing more storage accessible through the rear hatch window. The insert will be bolted to body points in the floor front and back.

Stay tuned for the rest of this build.