You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Jack suggestions and recommendations

- Thread starter eaneumann

- Start date

Hello Mike:I found that one needs at least two jacks to change a flat tire.

Could you elaborate on this? I don't doubt you, but I think I'm missing something. Do you mean that it takes two different types of jacks to always the correct one for a given situation?

Thanks,

Howard

Dave in AZ

Well-known member

Several folks up above detailed using 2 jacks to safely change tire on unstable ground, if you want to read up above on details. Mep1811 just is agreeing.Hello Mike:

Could you elaborate on this? I don't doubt you, but I think I'm missing something. Do you mean that it takes two different types of jacks to always the correct one for a given situation?

Thanks,

Howard

Fenderfour

Well-known member

I’ve thought about doing a H1 Hummer jack too, but all of my experiences with a scissor jack haven't been great. It could be very handy in a lot of situations And I’m sure this jack is much more stable than most. In this situation I think theres a lot of things that I could’ve done to get out of the situation if my truck had fallen off of my jack. But ease of use, safety, and vehicle damage are what I’m concerned with. I want this to be easy. None of us get to travel as much as we‘d like. I’m not out there to work on my truck or get stuck (especially with my wife!). If I had been traveling with my group of dude friends, we would’ve had multiple jacks and people to help. I even would’ve finished the trail without a spare. We live in Colorado and most of our travel is to the Pacific Northwest. Sand was a new learning experience for me for sure.

Currently these are the options I’m leaning towards:

Tauler Jack/ARB Jack and OEM bottle jack with DIY attachments/base

Tauler Jack/ARB Jack and Pro Eagle 3 ton jack

Tauler Jack/ARB Jack and H1 Hummer jack with DIY attachments/base

One of my biggest concerns is keeping this fun and manageable for the wife. I don‘t want her using a Hi Lift and I wonder if she‘ll be able to use the Tauler Jack. It seems like it’s pretty hard to turn under load, but I’ve never used one or seen one in person. Might make one to test out, but that’s why the ARB Jack is on my mind. I‘ve also read mixed things about storing the ARB Jack on its side. I‘d be surprised if its a real issue, but something to consider. I would‘ve never considered the Pro Eagle if I didn’t already own one. If I found a bag for it or had one made, that could be a good option. I bought it when they first came out to use on my gravel driveway. Maybe even a smaller Bad Lands off road jack could work well. Weight savings is also a consideration, this thing is heavy.

Thanks for all of the great replies so far! Also some more pictures because that’s half the reason we’re here.

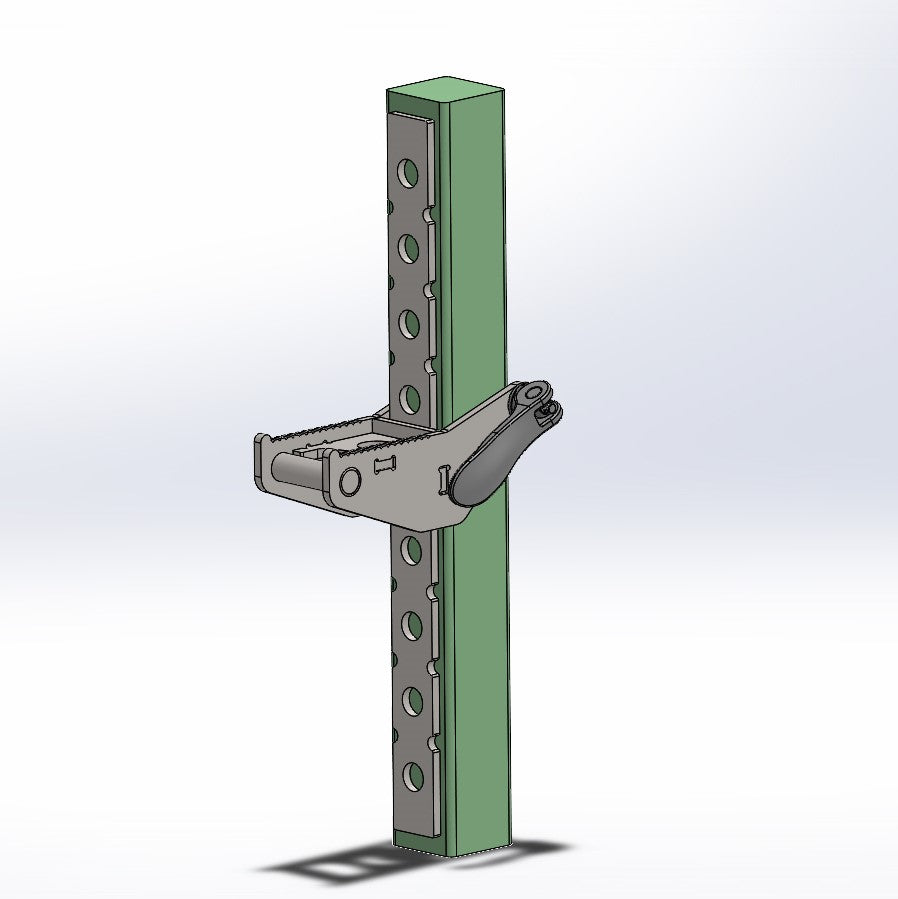

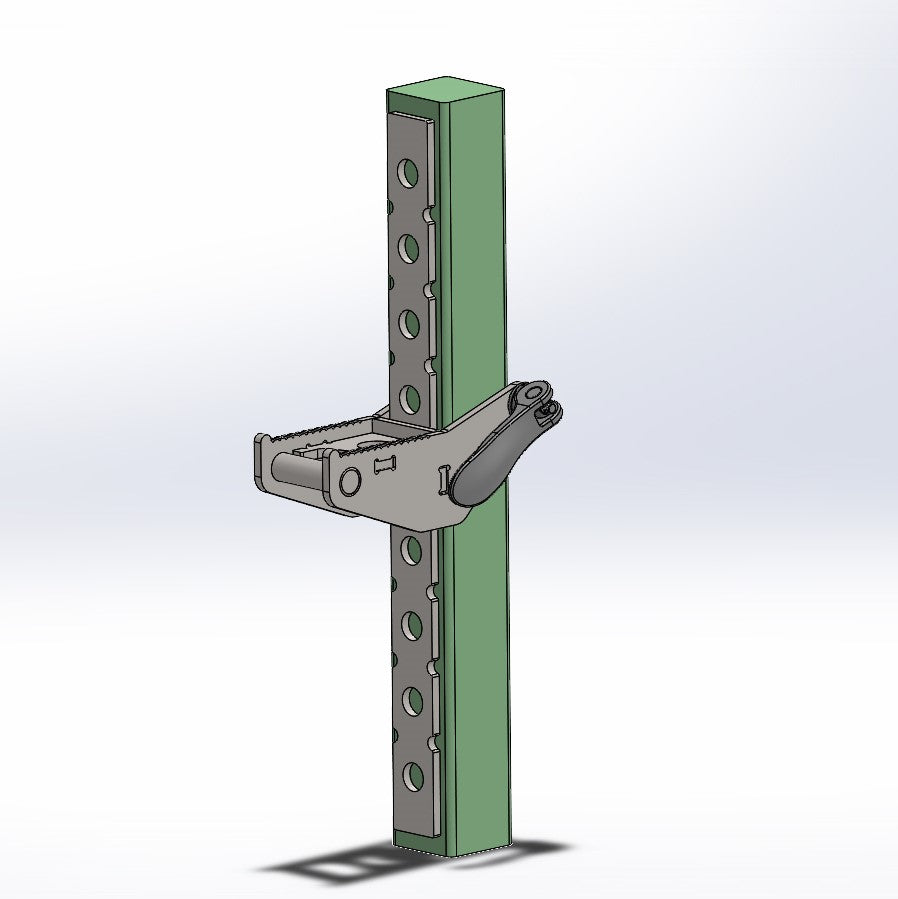

I put together a tauler jack and replaced the handle with a 1/2 socket receiver. I disassembled the jack (4 screws, 1 ring) and cut the handle off, then welded an old 1/2" extension on to the shaft section that carries the bevel gear inside the jack head. Now my handle is a 1/2" extendable ratchet. This solves the issue with overhead space (the handle doesn't have to swing over the head), and allows a user to use the rotational position that gives the most torque. The extendable handle also allows for more torque. I did add a foding handle as well, but I'm not sure that's very useful. It helps quickly raise and lower then jack when it's not loaded, but once loaded I usually just push using the ratchet mechanism.

In spite of having a way to use an impact driver on my jack, Brandon (the maker of tauler jacks) doesn't recommend using it. I agree with this. The percussive force of an impact driver will wear the jack internals very quickly.

I've been using the tauler to jack up the front or rear bumper to lift the entire end of my truck. I have plans to add a bar and pin to fit in my hitch receiver to create a more positive connection than just the jack's teeth.

mep1811

Gentleman Adventurer

When a tire goes flat, especially taller tires, a jack is needed to lift that tire off the ground. Usually that will bring a jack to it's limit of travel. The flat tire can be removed but the axle is not high enough to fit a fully inflated tire to the hub. That is where a second jack comes into play to lift the axle high enough to get the tire on.Hello Mike:

Could you elaborate on this? I don't doubt you, but I think I'm missing something. Do you mean that it takes two different types of jacks to always the correct one for a given situation?

Thanks,

Howard

craig333

Expedition Leader

I've had to use the hi lift to raise my truck high enough to get the bottle jack under the axle. You may be able to dig to get enough room depending on terrain.

I got to see the ARB jack in use on the rubicon. I used to think they were way too expensive but I'm getting older. It may be time for me to spend the extra cash and get something easier to use than a hi lift.

I got to see the ARB jack in use on the rubicon. I used to think they were way too expensive but I'm getting older. It may be time for me to spend the extra cash and get something easier to use than a hi lift.

IdaSHO

IDACAMPER

You definitely need to know how short of a jack thats needed, if you intend to jack from the axle housing or knuckle.

For my superduty, I found a simple "shorty" bottle jack that not only fits with a flat tire, but has enough throw to do a wheel/tire change without resetting.

As for two jacks.... instead, having a jack stand serves the same purpose, at least with the correct size bottle jack. Just have to do the math.

For my superduty, I found a simple "shorty" bottle jack that not only fits with a flat tire, but has enough throw to do a wheel/tire change without resetting.

As for two jacks.... instead, having a jack stand serves the same purpose, at least with the correct size bottle jack. Just have to do the math.

fourfa

Observer

I’m extremely happy with the used H1 jack I got from some military surplus seller on eBay. These used to be appealingly cheap, but the word has been out for years now so they’re pricy enough now to make you think twice. Anyway, the advantages of wide base plate that won’t sink in soft sand, low stack height when all the way down, and high lift height mean that realistically, you only need the one jack. I did make my own axle adapter - the stock round pin is useless by itself unless you literally own a H1 with the matching sockets all over. Pics here if it’s any help.

Not hating on the idea of two jacks to be sure - two is one, one is none etc - but for me I’m confident enough in this to only carry the one. And yes I have tested with fully deflated tires in field conditions

Not hating on the idea of two jacks to be sure - two is one, one is none etc - but for me I’m confident enough in this to only carry the one. And yes I have tested with fully deflated tires in field conditions

dstefan

Well-known member

Has anyone heard of this jack:

Looks like an exact knock off of the ARB jack for about 60% of the price. There’s a (very) few good reviews and it appears to be well made, if you can believe the descriptions. Would be tempting except for the usual made in China hesitations for any recovery gear.

Just curious . . . Seems like the ridiculous price of the ARB would have to be challenged some time.

BUNKER INDUST Hydraulic Lift Jack.

Found it on Amazon (so you’d have to search, since I still think we can’t link to Amazon here anymore?)Looks like an exact knock off of the ARB jack for about 60% of the price. There’s a (very) few good reviews and it appears to be well made, if you can believe the descriptions. Would be tempting except for the usual made in China hesitations for any recovery gear.

Just curious . . . Seems like the ridiculous price of the ARB would have to be challenged some time.

Metcalf

Expedition Leader

I'd vote Tauler Jack, but I am a little biased.....

I'm the guy that came up with the kit/concept/idea...

My general opinion on off-road jack requirements. There are recovery type jacks ( Tauler Jack, Farm jack, ARB, etc ) and there are repair jacks ( bottle jacks, floor jacks, etc ). While they can overlap, they don't replace each other fully. I still carry a small Toyota double extending screw style bottle jack in most of my off-road vehicles for working the vehicle and in very compact areas. Personally, I don't like working under a hydraulic jack, I like having a mechanical jack that has no bleed down or seal blow risk, something more like a jack stand if you will.

To make any recovery style jack work well, you really need bumpers and rockers that allow working 'around' the vehicle with that style jack. Being able to use a recovery style jack and lift directly at the wheel is one of the most under-rated techniques in my option. This can not only help you get material, mats, or boards under the tires, it can also help you get your 'repair' jack under the axle in some situations. I have a chain nose kit for the Tauler Jack which makes this very easy.

As far as your lifting 'effort' concern. It is very easy to expend the handle length to reduce effort if needed, but I find that for most uses a normal health person can lift a single corner with one hand, and lifting an entire end/side of a vehicle takes two hands. I built a modular ratchet handle for my personal 'daily' use TJ that uses a small ratchet with a folding handle. With the handle folded out, this gives some more leverage when needed. There are a ton of options to reduce the input force if that is what you end up needing.

If you have any other questions, please let me know. I'll sub this thread also as I don't get into the forums as much these days.

Tauler Jack Kit

Note: Summer 2025 update. 2.25 kits have been staying in stock. 2.5lite kits are still a short run low volume seller, but currently in stock with minimal lead time if you happen to fall between batches (as of July 2025) A recent rush from an excellent article written on Fourwheeler sent sales...

brennans-garage.com

I'm the guy that came up with the kit/concept/idea...

My general opinion on off-road jack requirements. There are recovery type jacks ( Tauler Jack, Farm jack, ARB, etc ) and there are repair jacks ( bottle jacks, floor jacks, etc ). While they can overlap, they don't replace each other fully. I still carry a small Toyota double extending screw style bottle jack in most of my off-road vehicles for working the vehicle and in very compact areas. Personally, I don't like working under a hydraulic jack, I like having a mechanical jack that has no bleed down or seal blow risk, something more like a jack stand if you will.

To make any recovery style jack work well, you really need bumpers and rockers that allow working 'around' the vehicle with that style jack. Being able to use a recovery style jack and lift directly at the wheel is one of the most under-rated techniques in my option. This can not only help you get material, mats, or boards under the tires, it can also help you get your 'repair' jack under the axle in some situations. I have a chain nose kit for the Tauler Jack which makes this very easy.

As far as your lifting 'effort' concern. It is very easy to expend the handle length to reduce effort if needed, but I find that for most uses a normal health person can lift a single corner with one hand, and lifting an entire end/side of a vehicle takes two hands. I built a modular ratchet handle for my personal 'daily' use TJ that uses a small ratchet with a folding handle. With the handle folded out, this gives some more leverage when needed. There are a ton of options to reduce the input force if that is what you end up needing.

If you have any other questions, please let me know. I'll sub this thread also as I don't get into the forums as much these days.

Thanks for the clarification. I'll admit that I've never had that problem. If I can't get my jack under the axle of the fully deflated tire, I just drive that tire up onto two or more of the 2x12" leveling boards I carry. Then slide my jack under the axle.When a tire goes flat, especially taller tires, a jack is needed to lift that tire off the ground. Usually that will bring a jack to it's limit of travel. The flat tire can be removed but the axle is not high enough to fit a fully inflated tire to the hub. That is where a second jack comes into play to lift the axle high enough to get the tire on.

Howard

craig333

Expedition Leader

I'm not at all sure I could have driven it up on anything.

craigruth.smugmug.com

craigruth.smugmug.com

Blackrock - Craig Ruth

This photo hosted by SmugMug; your photos look better here.

Similar threads

- Replies

- 6

- Views

- 459

- Replies

- 0

- Views

- 485

- Replies

- 0

- Views

- 227