Stoffregen Motorsports

Explorer

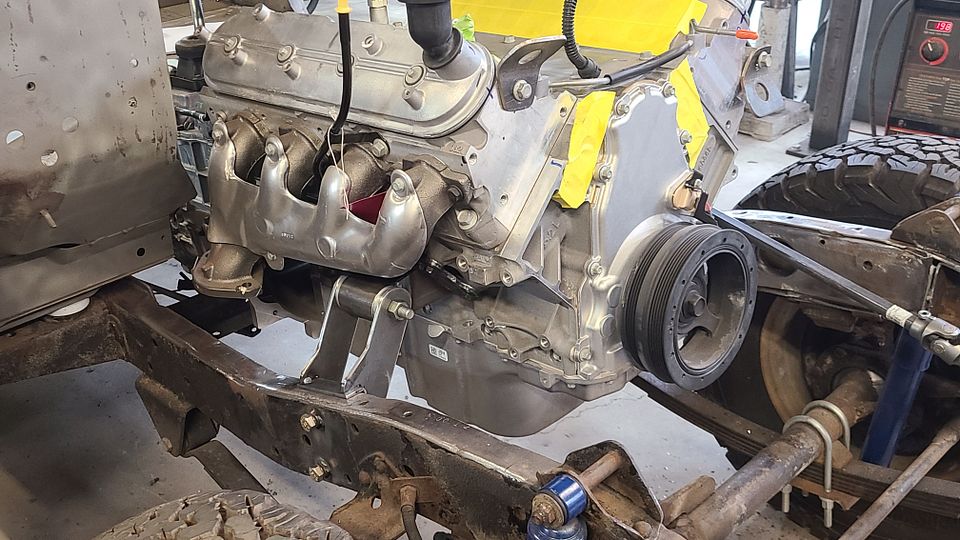

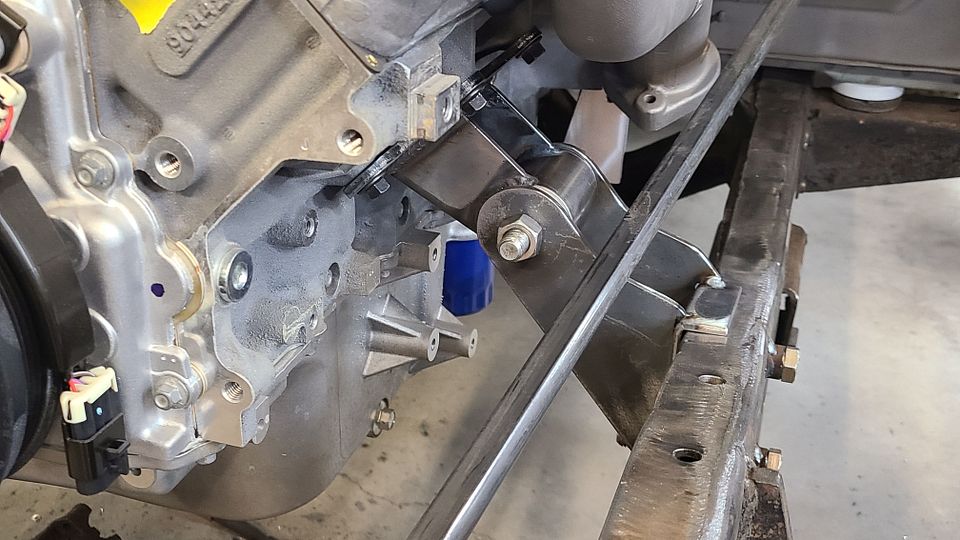

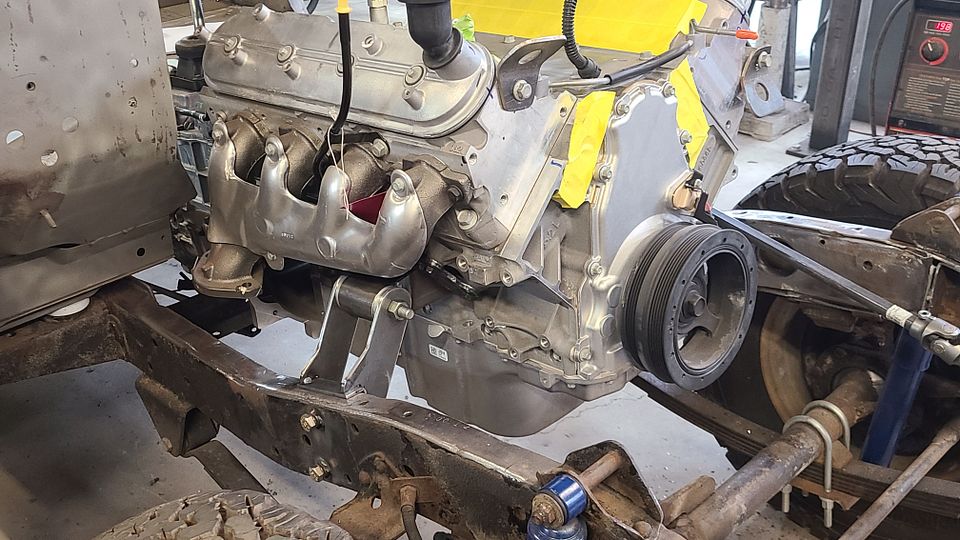

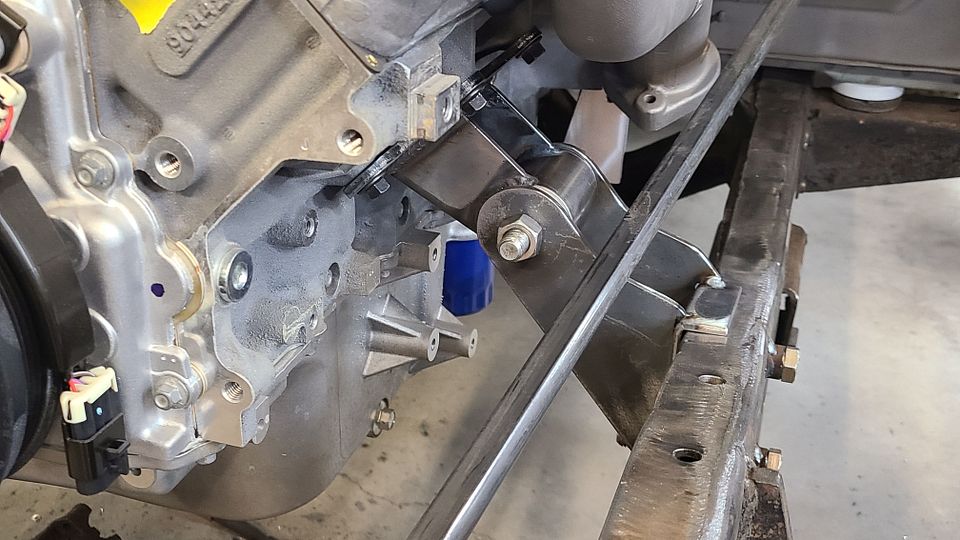

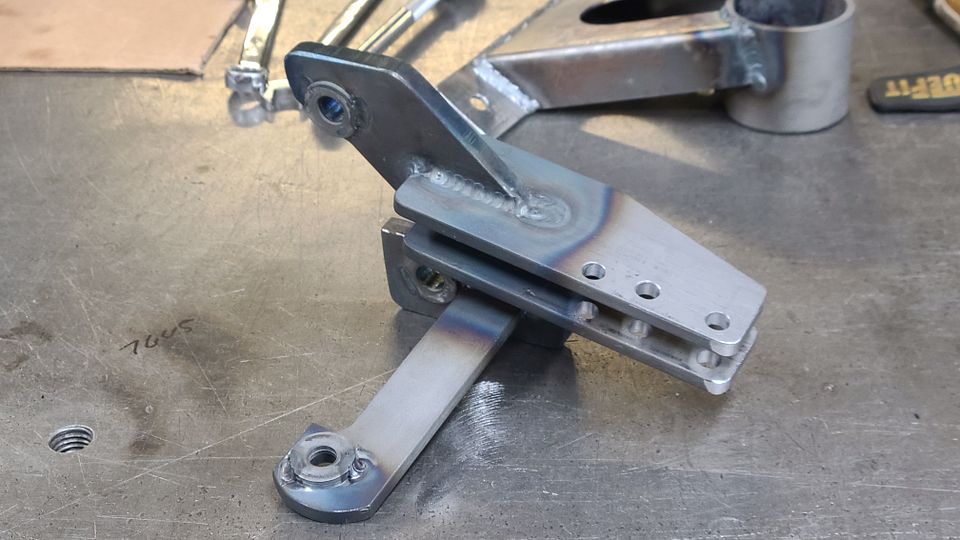

The motor mounts I started with were the basic Advance Adapters cushion style mounts, and would need to be modified to fit the steering shaft, so instead, I decided to build custom motor mounts to fit around the shaft. The new mounts look a lot better than the generic mounts and will also control the engine movement more, which is important since the engine bay is so tight. I used machined aluminum CJ5 leaf spring mock up bushings to make the motor mounts, which will be replaced with urethane during final assembly.

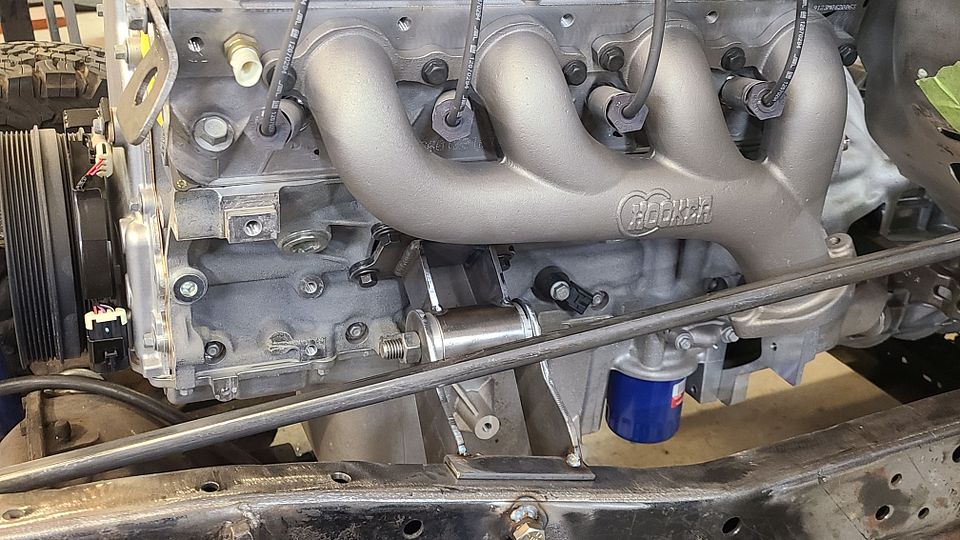

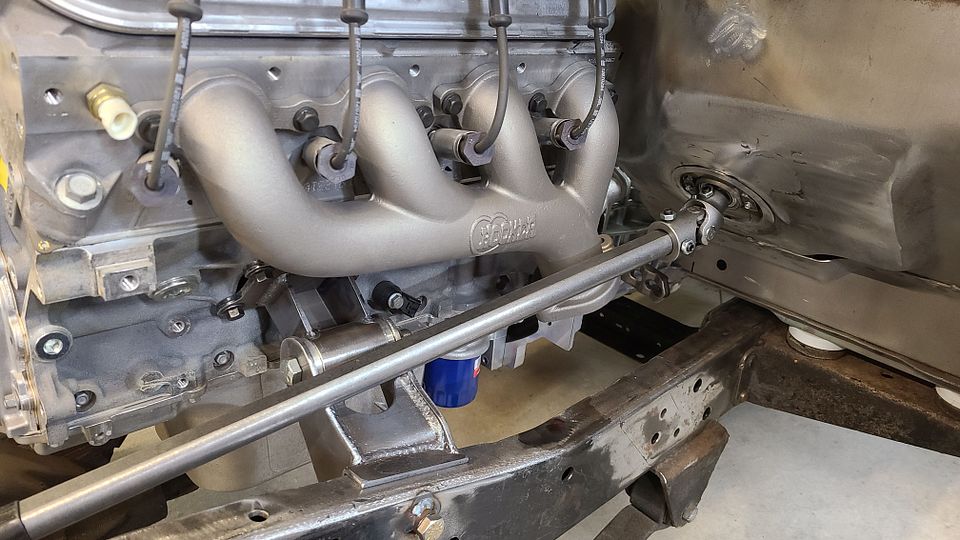

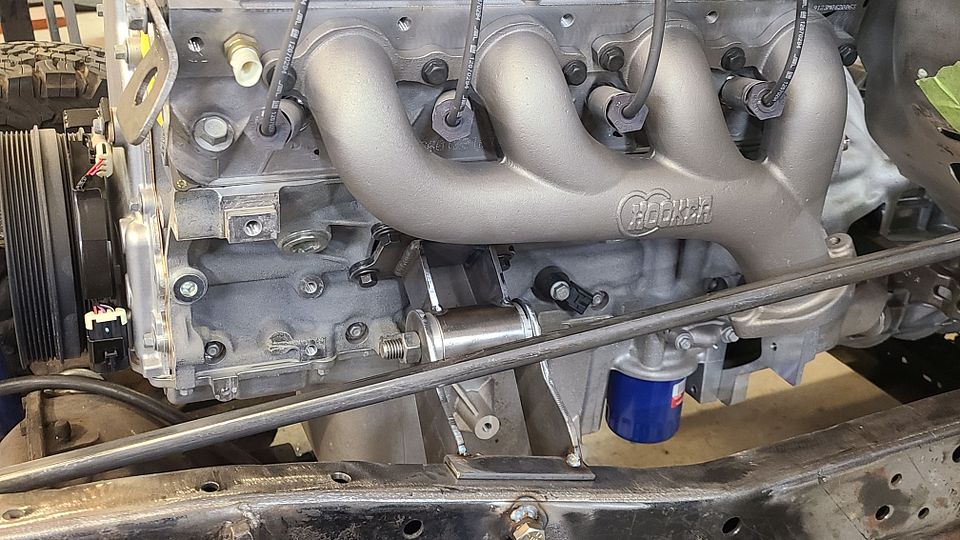

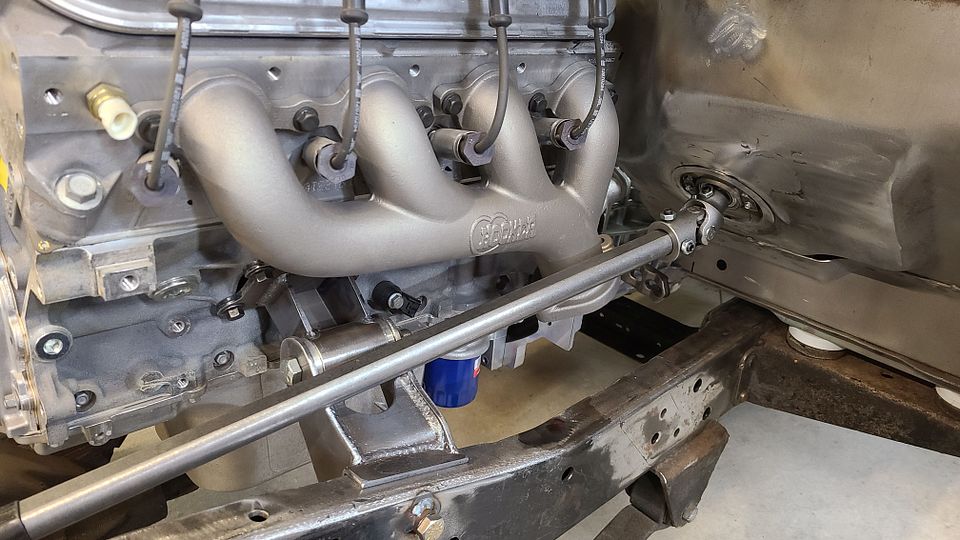

One more item got in the way of the steering shaft; the stock LS3 exhaust manifolds. The steering shaft was pointed directly at the wide outlet and instead of using a second u-joint and support bearing in the shaft assembly, a pair of Hooker exhaust manifolds were installed. These gave enough room to utilize a collapsible shaft in one shot from the box to the column. These manifolds also led to another problem, which I will discuss later.

The motor mounts I started with were the basic Advance Adapters cushion style mounts, and would need to be modified to fit the steering shaft, so instead, I decided to build custom motor mounts to fit around the shaft. The new mounts look a lot better than the generic mounts and will also control the engine movement more, which is important since the engine bay is so tight. I used machined aluminum CJ5 leaf spring mock up bushings to make the motor mounts, which will be replaced with urethane during final assembly.

.jpg?width=960&height=720&fit=bounds)

.jpg?width=960&height=720&fit=bounds)

.jpg?width=960&height=720&fit=bounds)

One more item got in the way of the steering shaft; the stock LS3 exhaust manifolds. The steering shaft was pointed directly at the wide outlet and instead of using a second u-joint and support bearing in the shaft assembly, a pair of Hooker exhaust manifolds were installed. These gave enough room to utilize a collapsible shaft in one shot from the box to the column. These manifolds also led to another problem, which I will discuss later.

The motor mounts I started with were the basic Advance Adapters cushion style mounts, and would need to be modified to fit the steering shaft, so instead, I decided to build custom motor mounts to fit around the shaft. The new mounts look a lot better than the generic mounts and will also control the engine movement more, which is important since the engine bay is so tight. I used machined aluminum CJ5 leaf spring mock up bushings to make the motor mounts, which will be replaced with urethane during final assembly.

.jpg?width=960&height=720&fit=bounds)

.jpg?width=960&height=720&fit=bounds)

.jpg?width=960&height=720&fit=bounds)

.jpg?width=960&height=720&fit=bounds)

.jpg?width=960&height=720&fit=bounds)