If you have factory A/C and don't "need" it then that can be converted over to an On-Board air system. I did this to my TJ last summer after running the mighty MV-50 for years. My goodness, why didn't I do this sooner since I had the A/C sitting there the whole time!!!!!

Pardon the link to Jeepforum, but that's where I tend to post my write-ups:

Click the link to the write-up for details. But here's an overview:

Speed

I don't know the actual CFM of the system but it takes the following amount of time for each tire size from 14-30 psi:

45 seconds = 33x10.50

55 seconds = 33x12.50

70 seconds = 35x12.50

After running the little MV-50 for ~5 years I am freak'n LOVING this mod. I'll usually air up 2 other rigs besides mine at the end of a trail run because it's so fast.

Pressure

Don't worry about it. We only need to get up to about 30-35 psi. The factory A/C system has a high pressure switch that turns on if pressure DROPS to 350 psi and shuts off at 420+ psi. So, yeah, airing up tires is not an issue. That said, I have pressure switch in the system that turns on below 90 psi and shuts off at 120 psi.

A Simple System

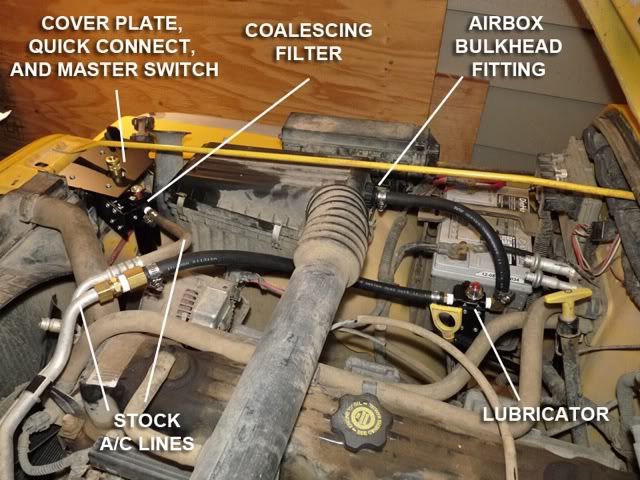

Since I only wanted to air up tires I just have the lubricator, filter, pressure switch, master switch and necessary plumbing. I didn't even bother with a pressure regulator to say nothing of a lack of air tank or multi-point quick disconnects. The system uses the factory A/C compressor and the hard metal lines snaking up and over the engine. It taps into the factory air filter box for filter air. And the air lines pretty much follow the stock A/C line routing. There is a cover plate for the front bracket / coalescing filter that has the master switch mounted on it and a hole for the only quick disconnect. The quick disconenct is covered with a rubber chair leg tip to keep dust and mud out of it. It fits perfectly. For the hose, I have a regular gas-station-type air chuck with built-in pressure gage on the end of a 25 ft self coiling hose. This is kept in a small 12" tote bag from Home Depot. So much easier and faster to set up and put away than the MV-50. Lighter to haul out of storage, too.

Operation

With the engine running I just pop the hood, plug in the air hose, then flick on the master switch. That's it. The pressure switch will automatically engage the A/C clutch and run the pump until it trips the upper pressure setting. All I do is just go from tire to tire airing up . . . then handing off the air hose to a friend or two so they can air up their rigs.

The operation of the pump is surprisingly quiet itself. . . but you have the engine running with the hood open. So you have an engine idling as your noise source. MUCH quieter and less annoying than the Brrrrrrrrrrrr of an electric pump.

Cost

The system cost me ~$200 but I had to do some tight shopping and hunting for those prices. Figure maybe $250-ish if you're a little less careful. Big cost areas are the lubricator and the coalescing filter. They'll run you about ~$120+ total. The rest of the stuff will nickel and dime you to the total with another big cost point being the pressure switch (~$20) and the brass fittings.

Don't Cheap Out

Part of the cost for the lubricator and filter is that you NEED good quality, high temperature rated components. Find units with metal bowls rated to 175 F.

Ease of Install

The toughest part would be the welding and fabrication of the brackets . . . if you can't weld. The second toughest part is simply gathering all the parts. The rest of it is a matter just screwing stuff together.

Alternatives

If you don't want to give up your a/c then check out Kilby Enterprises for all the York-based OBA setups. It'll be a lot more costly but you'll get a solid system based on the york compressors which actually put out more air than this system.

I made some brackets to hard mount the lubricator and the coalescing filter.

The system taps into the factory air filter box above the filter. Using the

engine air filter keeps things a bit simpler.

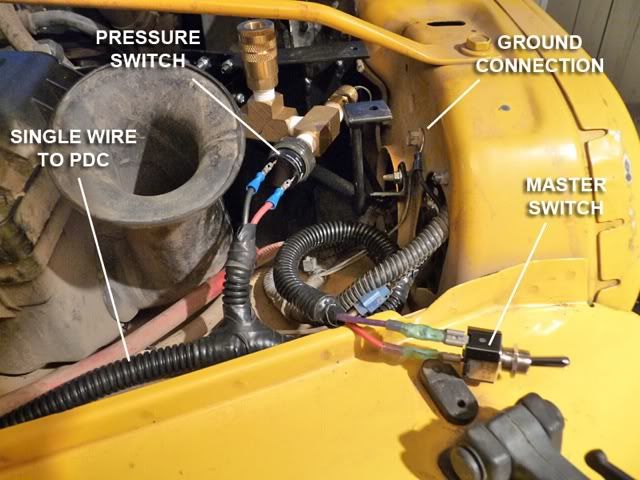

I spliced into the A/C clutch relay in the PDC to run a wire to my two switches

(master switch and pressure switch). This way I used the entire stock wiring

harness including fuse, relay, factory plugs, and routing out to the A/C clutch.

This is the extent of my wiring harness. Most of it is the 3 ft lead to the PCD

that splices into the A/C clutch relay. What's seen here it an in-line set up going

to the master swtich, then from the master switch to the pressure switch, then

to ground. Pretty simple. The rest of it it uses the factory wiring harness to

the A/C clutch.

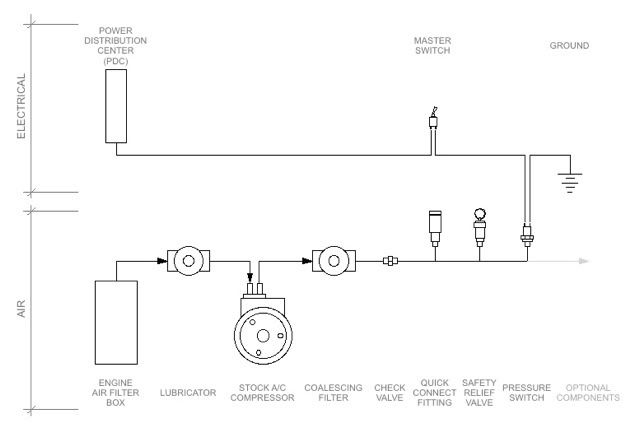

Conceptually, the system looks like this.

The finished system.