luthj

Engineer In Residence

Here is some data on my Lifeline battery bank.

Specs:

2x GPL-8D 255x2=510AH

Wired for 12V

Charged by 640W solar array and outback controller

Charged by Alternator fed with 2/0 and 4/0 cable (~13.9V, later modified to 14.2).

I did a capacity test today. As I didn’t feel like spending 8 hours doing the 25A (50A total) test, I connected a 100A load and did a C/5 rate test.

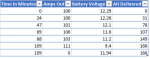

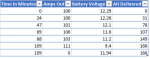

Take a look at the table below. The numbers should speak for themselves.

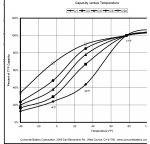

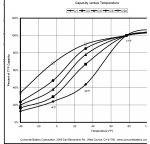

These 8D batteries delivered 166AH before dropping below 10.5V under a C/5 load. The battery averaged 60F during the test. Based on the lifeline capacity-discharge-temperature plot, a new battery would deliver about 90% of new capacity at 60F.

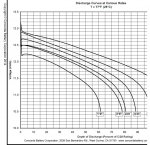

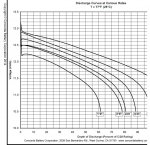

Based on the discharge rate plots, the C/5 rate would deliver 80% of rated capacity. So the battery should deliver 0.9*0.8*510AH= 367AH

My batteries delivered 166AH 166/367=45% of new capacity. Now the battery did recover to 11.9V with about 10 seconds of the load being removed. So obviously there was still significant capacity left. Based on lifelines OCV vs DOD charts, I would estimate the batteries had another 25% of capacity left. This is probably inaccessible due to low plate porosity driven by low charge rates. A couple recharge cycles with 400A+ charge rates would likely make more of this capacity available at the 100A discharge rate.

So the adjusted capacity of my bank is about 221AH, or 221/367= 60% of new (at C/5).

So how many cycles has this battery delivered?

The bank has delivered 74kAH. We have been using the van regularly for around 700 days. 74,000/700=106AH average cycle depth. That is 510/106= 20.7% DOD average. So 700 20% cycles is a rough estimate. Lifelines Lab testing shows over 2000 cycles to 20% DOD. But that is only to 80% of new capacity! If I used that metric my batteries only delivered 350 20% DOD cycles!

Since I first setup the MATE, the system has spent about 240days (5760 hours) at “100%”. About 2000 of those full hours occurred during our full-time travels.

At a cost of about $1400, that comes to a cycle cost of 2$ per cycle. Or better thought of as 74,000kAH/1400$=52AH delivered per dollar.

What would I do differently? Early on I misunderstood how the MATE charge termination works. Because of this the absorb charge was often terminated before the return amps condition was met. How much this degraded the batteries, I will never know. This is a VERY common issue with solar and shore power chargers, so I suspect this type of capacity walkdown is endemic to the full-time off grid RV/Marine industry.

So, I would keep charge voltages near the high side of recommended, sometimes higher for charge regimes that are not optimal. For highly stressed batteries perform a recovery charge for about ¼ the recommended time every 6 months (if called for by resting voltages).

Do not terminate the absorb phase until return amps drops below 0.75% (ideally 0.5%) of rated capacity. This means less than 0.75A for a 100AH battery.

Go with lithium. Given that decent lithium setups can be found for around 7-10$ per AH, and 2000 real world cycles. Or 900$/200,000Kah= 222AH delivered per dollar.

Obviously, it is the partial state of charge cycling, and not enough true 100% charges that reduced the cycle life on my lifeline batteries.

Specs:

2x GPL-8D 255x2=510AH

Wired for 12V

Charged by 640W solar array and outback controller

Charged by Alternator fed with 2/0 and 4/0 cable (~13.9V, later modified to 14.2).

I did a capacity test today. As I didn’t feel like spending 8 hours doing the 25A (50A total) test, I connected a 100A load and did a C/5 rate test.

Take a look at the table below. The numbers should speak for themselves.

These 8D batteries delivered 166AH before dropping below 10.5V under a C/5 load. The battery averaged 60F during the test. Based on the lifeline capacity-discharge-temperature plot, a new battery would deliver about 90% of new capacity at 60F.

Based on the discharge rate plots, the C/5 rate would deliver 80% of rated capacity. So the battery should deliver 0.9*0.8*510AH= 367AH

My batteries delivered 166AH 166/367=45% of new capacity. Now the battery did recover to 11.9V with about 10 seconds of the load being removed. So obviously there was still significant capacity left. Based on lifelines OCV vs DOD charts, I would estimate the batteries had another 25% of capacity left. This is probably inaccessible due to low plate porosity driven by low charge rates. A couple recharge cycles with 400A+ charge rates would likely make more of this capacity available at the 100A discharge rate.

So the adjusted capacity of my bank is about 221AH, or 221/367= 60% of new (at C/5).

So how many cycles has this battery delivered?

The bank has delivered 74kAH. We have been using the van regularly for around 700 days. 74,000/700=106AH average cycle depth. That is 510/106= 20.7% DOD average. So 700 20% cycles is a rough estimate. Lifelines Lab testing shows over 2000 cycles to 20% DOD. But that is only to 80% of new capacity! If I used that metric my batteries only delivered 350 20% DOD cycles!

Since I first setup the MATE, the system has spent about 240days (5760 hours) at “100%”. About 2000 of those full hours occurred during our full-time travels.

At a cost of about $1400, that comes to a cycle cost of 2$ per cycle. Or better thought of as 74,000kAH/1400$=52AH delivered per dollar.

What would I do differently? Early on I misunderstood how the MATE charge termination works. Because of this the absorb charge was often terminated before the return amps condition was met. How much this degraded the batteries, I will never know. This is a VERY common issue with solar and shore power chargers, so I suspect this type of capacity walkdown is endemic to the full-time off grid RV/Marine industry.

So, I would keep charge voltages near the high side of recommended, sometimes higher for charge regimes that are not optimal. For highly stressed batteries perform a recovery charge for about ¼ the recommended time every 6 months (if called for by resting voltages).

Do not terminate the absorb phase until return amps drops below 0.75% (ideally 0.5%) of rated capacity. This means less than 0.75A for a 100AH battery.

Go with lithium. Given that decent lithium setups can be found for around 7-10$ per AH, and 2000 real world cycles. Or 900$/200,000Kah= 222AH delivered per dollar.

Obviously, it is the partial state of charge cycling, and not enough true 100% charges that reduced the cycle life on my lifeline batteries.

Last edited: