PCO6

Adventurer

2x4 is a big cabinet!

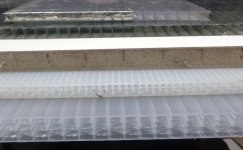

I'm constructing a 2'x2'x4' "garage" for the front of a square back trailer I'm building. I'm trying to go with as little wood as possible for the build ... hopefully none. I'm using PVC panels that are 3/16" thick. They're actually drop ceiling panels - about $20 from Lowe's. Most of the internal structure is also PVC 1" "lumber" with some steel reinforcement. The PVC has been easy to work with using basic wood working tools and products (table saw, router, brad nailer, pocket screws, adhesives, etc.).

This is a bit of an experiment and so far so good. I'll seal all of the seams and likely spray the box with Raptor Liner. It will be attached to the frame and not the trailer cabin. In the end if it fails or I'm not happy with it I'll go to Plan 'B' ... although I'm not sure at this time what that is.