Lowly Update:

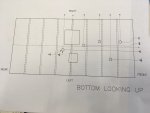

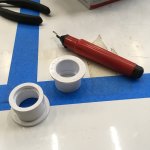

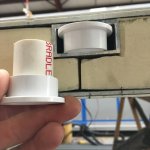

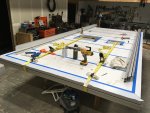

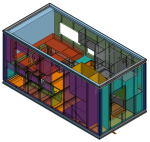

Before I could finish running electrical in the lid of the habitat I needed to cut the holes for the fan and skylight. Wiring needed to get to both these voids along with a can light that used the same access tube. I first laid out painters tape in the approximate areas of the cutouts, marked and triple checked not only the required size of the cutouts but the layouts I had drawn on the top of the lid. Not trusting my ability to draw the same round-cornered box at the same location on both sides of the lid panel I devised a plan to use a 3D printed drill guide along with a 3/16" feeler bit to drill holes at the center points of the radiused corners.

Once all 4 holes were drilled through the panel, perpendicular to the plane of the panel I made a cardboard template of the cutout hole with 3/16" holes in the same location as the holes just drilled in the panel. Using 3/16" drill bits to serve as pins, I pushed the "pins through the panel holes until they protruded through both sides of the panel. I then was able to climb underneath the panel (which is up on saw horses), slip the cardboard template over the pins and trace its outline onto the bottom of the panel. With the pins were perpendicular to the panel I knew with some certainty the layout on the bottom of the panel now matched the size and location as its corresponding layout on the top side.

Using a circle cutter centered on the 3/16" radius center holes, I then cut through the panel's skin on the top and then from below.

With the "coins" removed from the corners of both the top and bottom of the cutout, I was then able to pass a long jigsaw blade through the remaining foam and start cutting the sides of the cutouts quite easily.

****WARNING****: Jigsaws are evil! When trying to cut even a straight line through a thick panel the blade will begin to flex sideways resulting in a cutout that will result in elevated blood pressure and gnashing of teeth. Stay away from jigsaws!

After inferior results using the jigsaw to make the entire cut, I switched over to a vibrating tool with much better results, but requiring cuts on both sides of the panel. Foam between the cuts was sliced using a long bladed razor while the jigsaw was reluctantly used for cutting the aluminum tubing.

With both holes cut, the moment of truth had arrived: would the fan and skylight actually fit into the holes. Drum roll please. . .

Thankfully the mounting flanges will hide the screwups made by the jigsaw and everything will look like it was done by a professional - ha! Glad to have these cutouts behind me so the lid wiring can get finished up. I'll definitely continue to employ the drill guide/pin/template/layout technique but avoid the using the jigsaw on long cuts like hemorrhagic fever.

- Sheik