jaleel_da_sheik

Observer

Lowly Update:

With the tail lighting mainly complete it was time to turn the attention to the winch's wiring. Keep in mind that the previous winch was hydraulically driven off of the truck's now removed PTO and this new Mile Marker winch is driven off of the truck's 24 volt power. Wiring for the winch control plug-ins and emergency stop buttons located at the front and rear of the truck had to be traced and sorted out in order to integrate them into the new winch's control wiring.

It was a spaghetti noodle mess for awhile but we finally managed to crack the nut and got the new winch to operate using the truck's power and the original controls. The E-stops even work as they should! I even managed to make a circuit sketch at the wiring box for posterity's sake.

Big thanks to a shop here in Grants Pass, Oregon called Alternative Power & Machine. Its one of those hole-in-the-wall shops that has everything needed for wiring up power throughout a truck such as mine; the sort of shop where the employees actually know more about their product than you do. Great resource!

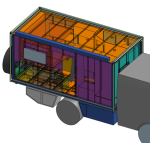

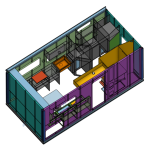

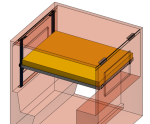

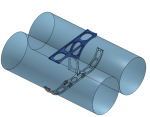

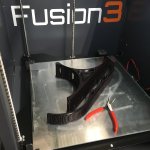

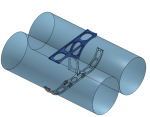

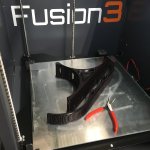

I'm now going through all of the truck's systems located between the chassis rails and underneath the soon-to-be installed habitat. This area is easily accessed right now but will become hard to reach (at best) with the habitat bolted on. The truck's compressed air tanks are located in this area and the last section of Lowly's once extensive rust. I decided to 3D print new cradles to both cushion the tanks from their hard mounts and allow better dirt and water passage around the tanks (which initially led to the concentration of rust).

Still waiting on the fresh paint to dry on the tanks, then I'll get to see if my cradles work as well as I hope.

- Sheik

With the tail lighting mainly complete it was time to turn the attention to the winch's wiring. Keep in mind that the previous winch was hydraulically driven off of the truck's now removed PTO and this new Mile Marker winch is driven off of the truck's 24 volt power. Wiring for the winch control plug-ins and emergency stop buttons located at the front and rear of the truck had to be traced and sorted out in order to integrate them into the new winch's control wiring.

It was a spaghetti noodle mess for awhile but we finally managed to crack the nut and got the new winch to operate using the truck's power and the original controls. The E-stops even work as they should! I even managed to make a circuit sketch at the wiring box for posterity's sake.

Big thanks to a shop here in Grants Pass, Oregon called Alternative Power & Machine. Its one of those hole-in-the-wall shops that has everything needed for wiring up power throughout a truck such as mine; the sort of shop where the employees actually know more about their product than you do. Great resource!

I'm now going through all of the truck's systems located between the chassis rails and underneath the soon-to-be installed habitat. This area is easily accessed right now but will become hard to reach (at best) with the habitat bolted on. The truck's compressed air tanks are located in this area and the last section of Lowly's once extensive rust. I decided to 3D print new cradles to both cushion the tanks from their hard mounts and allow better dirt and water passage around the tanks (which initially led to the concentration of rust).

Still waiting on the fresh paint to dry on the tanks, then I'll get to see if my cradles work as well as I hope.

- Sheik

Last edited: