Finished rotating the tires and torqued the wheels down this morning.

Time to start on the front push bar build. I needed to turn the truck around in the garage so I had to get some temporary power to the truck to start it since I removed the battery box.

Here's the push bar, it's built from 3.5" tubing (We thought this size fit proportionally with the size of the truck). Here we are getting ready to mark/cut the proper angle on the bottom of the tubing, we performed a test cut at the bottom of the tubing to verify the angle was correct.

Test cuts were right on the money so here we're marking out the final cuts.

We will be making the push bar easily removable for maintenance purposes etc. To bolt the push bar to the factory bumper we need to fill the step in the top of the bumper so the push bar base plates sit at an even height. Here we cut two pieces of steel to fill the step.

Here my father is removing paint from the bumper so we can weld on the plates (we changed our mind on this process as our plan evolved, more below).

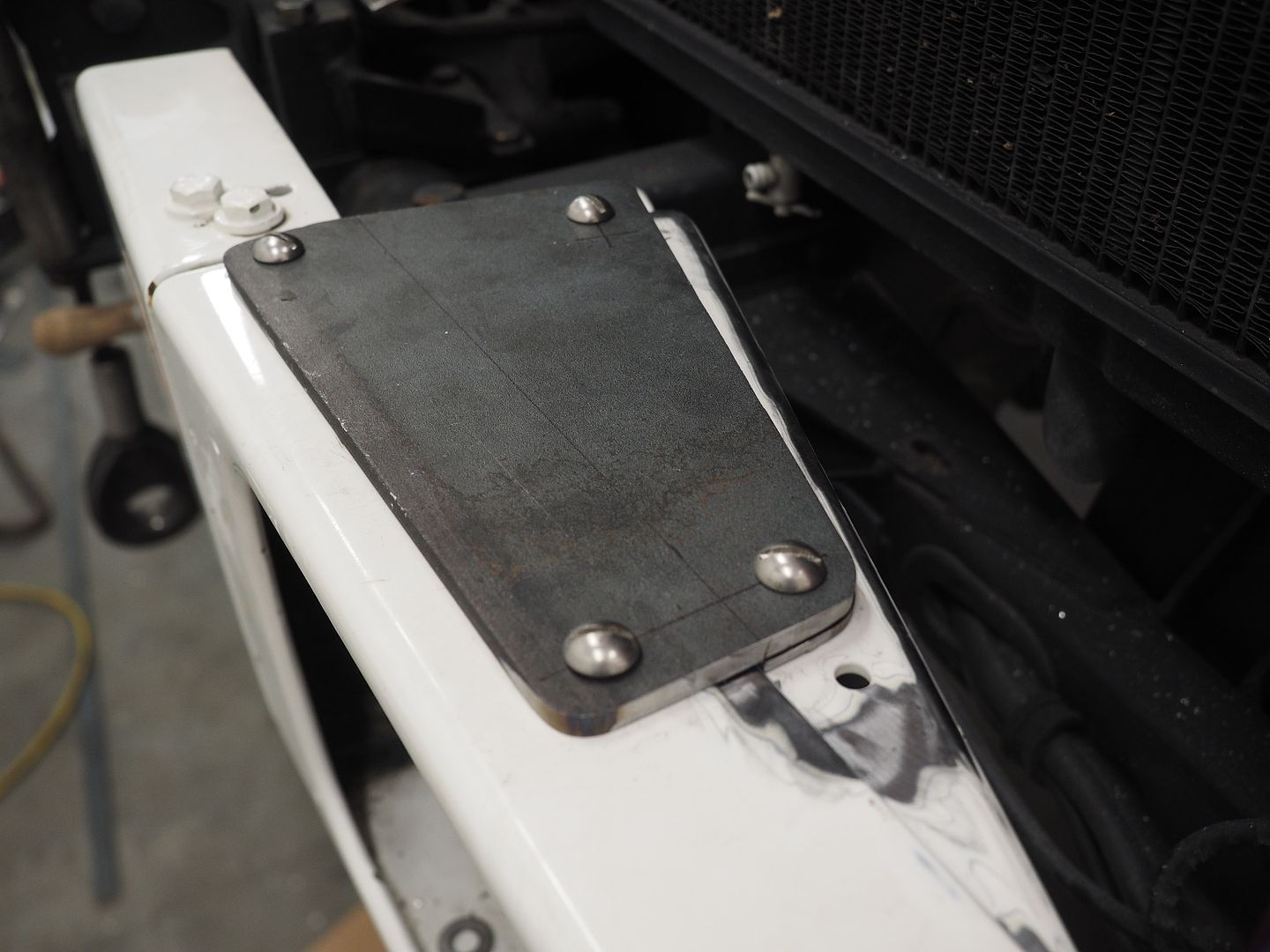

Here the base plates are cut and you can see how the bottom spacer plate is needed to let the base plates sit flush. The push bar will be welded to the top base plate.

Drilling the bolt holes. At this point we changed our plan and decided to keep the bottom spacer plate a bolt on unit as well. This will allow us to powder coat all the parts top and bottom and will prevent any rust between the plates.

Here the bottom plate has been trimmed to the same size/shape of the top plate, looks better this way.

And the push bar sitting in place for a preview. The bar still needs to be trimmed slightly for level and angled (The bar will slant out slightly away from the grill). Still have to fab mounts for the 20" light bar as well. Hopefully weld the bar to the base plates tomorrow.

Hodakaguy