Gullywagon

New member

I have been lurking around here for awhile and thought I would share a project that I have already begun. It's been a slow process and I am having to learn alot as I go. The single cab chassis that I am building on is a 1991 ex-Dutch military ambulance. I will be building a composite panel camper on the back. Initially I wanted a cabover camper but struggled with how large it would end up being. So I went back and forth many times, considered eliminating the cab over, but it still seemed too tall. I was pretty adamant about not wanting a fabric style pop-top. I found a camper in my researching that had a lower profile and only a portion of the roof popped up using hard sides. I thought hard about all the tradeoffs, and finally decided to go this route. What helped me decide on these various versions was a bunch of foam sheets I used to mock up the different designs so I could actually see what they looked like. I loved all the space the cabover would have. If you know about these Mercedes, then you know they are quite underpowered. This was a big consideration as I thought about this build. A more powerful engine could be swapped in, but I don't know anything about swapping engines and I think it would be quite expensive too. So thats one reason I wanted something smaller, not to mention tree branches and other obstacles and I think for a chassis like this something smaller and more nimble looks right to me.

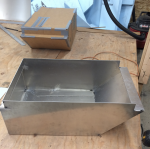

I will post some photos and updates when I can. I already have a subframe constructed, some storage boxes and just finished mounting in an auxiliary fuel tank. I will get some of those photos up here as well.