Switch

Observer

I just retired/replaced my old canoe rack. It was mounted on a traditional two-cross member rack with slots.

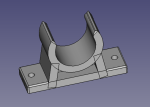

Figure 1: cross member canoe mounts. The top mount fits in the front rack position and cradles the bow from the outside of the gunwale. The bottom mount fits in the rear rack position and cradles the stern from the inside of the gunwale.

The key thing to understand about this design is that the top mount (shown above) is custom fitted to the outside dimensions of the gunwale of my canoe near the bow, while the lower mount is custom fitted to the inside dimensions of the gunwale of my canoe near the stern. The point is that their is exactly one location in the rack that is "correct". The reason I use the outside dimension on the bow is that the canoe will stop moving forward when I slide it into place because the bow is narrow and widens up to this point. And then the canoe will also fit the inside dimensions of the stern mount. The out side guides on the rear mount just keep the canoe from slipping off of the rack.

There are several advantages of this design:

1: It eliminates the task of centering the canoe on the truck since the rack is fixed and already centered.

2: Each canoe cradle has two fasteners securing it to the truck rack. So that if one comes loose, the canoe is still held securely by the other bolt.

3: The canoe slides easily over the HDPE plastic which also does not abrade the canoes parts at the mounting mount.

4: If a whole cradle is lose, the canoe is still secure on the cradle, it just slides from side to side. But the canoe is still held secure by the 1" webbing that is wrapped over the canoe.

Figure 2: Here are the new (improved) canoe mounts

Instead of wood, these are 100% HDPE plastic. The canoe slides much easier now & this will last much longer than the wood version. Also, the wood would expand and shrink and the bolts holding it to the rack would come loose. I think the HDPE will perform much better in this regard too.

Figure 3: The alternative is to use four separate gunwale mounts like this

Aside from costing $200, at least the rear mounts have to be adjusted separately every time you load the canoe. And each represents a single point of failure.

As you can see 10 years has really warn down the wood and Galvanized fasteners are at end of life.

So I recently upgraded to using HDPE plastic (instead of wood) and stainless steel hardware (Instead of Galvanized) on my new Tacoma.

Figure 4: The forward mount holds the bow gunwale from the outside.

Figure 5: The rear mount holds the gunwale from the inside.

With this design it takes only a few minutes to unload or load the canoe. It takes a few hours to build but still cost less than half of the Yakima parts. So it pays for itself in safety and convenience.

Figure 6: Canoe strapped in place. Big River, Mendocino California.

Figure 1: cross member canoe mounts. The top mount fits in the front rack position and cradles the bow from the outside of the gunwale. The bottom mount fits in the rear rack position and cradles the stern from the inside of the gunwale.

The key thing to understand about this design is that the top mount (shown above) is custom fitted to the outside dimensions of the gunwale of my canoe near the bow, while the lower mount is custom fitted to the inside dimensions of the gunwale of my canoe near the stern. The point is that their is exactly one location in the rack that is "correct". The reason I use the outside dimension on the bow is that the canoe will stop moving forward when I slide it into place because the bow is narrow and widens up to this point. And then the canoe will also fit the inside dimensions of the stern mount. The out side guides on the rear mount just keep the canoe from slipping off of the rack.

There are several advantages of this design:

1: It eliminates the task of centering the canoe on the truck since the rack is fixed and already centered.

2: Each canoe cradle has two fasteners securing it to the truck rack. So that if one comes loose, the canoe is still held securely by the other bolt.

3: The canoe slides easily over the HDPE plastic which also does not abrade the canoes parts at the mounting mount.

4: If a whole cradle is lose, the canoe is still secure on the cradle, it just slides from side to side. But the canoe is still held secure by the 1" webbing that is wrapped over the canoe.

Figure 2: Here are the new (improved) canoe mounts

Instead of wood, these are 100% HDPE plastic. The canoe slides much easier now & this will last much longer than the wood version. Also, the wood would expand and shrink and the bolts holding it to the rack would come loose. I think the HDPE will perform much better in this regard too.

Figure 3: The alternative is to use four separate gunwale mounts like this

Aside from costing $200, at least the rear mounts have to be adjusted separately every time you load the canoe. And each represents a single point of failure.

As you can see 10 years has really warn down the wood and Galvanized fasteners are at end of life.

So I recently upgraded to using HDPE plastic (instead of wood) and stainless steel hardware (Instead of Galvanized) on my new Tacoma.

Figure 4: The forward mount holds the bow gunwale from the outside.

Figure 5: The rear mount holds the gunwale from the inside.

With this design it takes only a few minutes to unload or load the canoe. It takes a few hours to build but still cost less than half of the Yakima parts. So it pays for itself in safety and convenience.

Figure 6: Canoe strapped in place. Big River, Mendocino California.

Attachments

Last edited: