Inspired largely by OVRLND campers and 97heavyweight's build thread, I've been planning a pop up camper build for a few months now. The general plan is similar to 97heavyweight's build: Aluminum extrusions for the frame (because I don't know how to weld, and don't have a great means to learn how at the moment), ACM for the siding, lot's of 3M VHB tape. The goal is a heated, insulated place to sleep on ski trips, and general camping trips. Being able to stand upright and also sit up in bed are requirements. I used to have a forester with a sleeping platform and not being able to sit upright was the worst thing about it. The ability to build the camper in my 1 car garage was also a significant requirement.

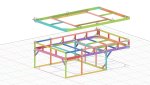

I started working through a CAD model in September and had finalized most details by November. I had to wait for some things to fall into place, but its finally time start the build. I finalized dimensions and ordered the aluminum extrusion from TNUTZ over the Christmas holiday, and it arrived last week. Major work on the build started over the weekend. I used a combination of anchor fasteners and end fasteners. I paid for tnutz to do the machining for the anchor fasteners, but did all of the tapping for end fasteners myself. Everything is built from the 15 series extrusions. Mostly the 1515, but some 1530 for the main structural parts of the cab-over.

About 8 hours of work on Saturday got most of the main part that sits on the truck bed completed. Another 6 hours on Sunday and most of the cab-over part was done, just a few more pieces to go before putting the roof together. Another 6 hours of work on Monday, thanks to the 3 day weekend, and the initial mock-up of the full frame is done. Next up is building the roof lifting bars, a test fit on the truck, then take it all apart to put back together with locktite.

I started working through a CAD model in September and had finalized most details by November. I had to wait for some things to fall into place, but its finally time start the build. I finalized dimensions and ordered the aluminum extrusion from TNUTZ over the Christmas holiday, and it arrived last week. Major work on the build started over the weekend. I used a combination of anchor fasteners and end fasteners. I paid for tnutz to do the machining for the anchor fasteners, but did all of the tapping for end fasteners myself. Everything is built from the 15 series extrusions. Mostly the 1515, but some 1530 for the main structural parts of the cab-over.

About 8 hours of work on Saturday got most of the main part that sits on the truck bed completed. Another 6 hours on Sunday and most of the cab-over part was done, just a few more pieces to go before putting the roof together. Another 6 hours of work on Monday, thanks to the 3 day weekend, and the initial mock-up of the full frame is done. Next up is building the roof lifting bars, a test fit on the truck, then take it all apart to put back together with locktite.