You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My M416 - Yes, another one

- Thread starter Kiddmen57

- Start date

brian90744

American Trekker

Kiddmen57

Supporting Sponsor

Sent you PM. I really like you lid. Here's mine. tx brian

Nice! I too have decided to extend my tongue at some point. With my RTT i either have to hang it all over the rear of the trailer, or not open the jeep gate with the trailer coupled.

Any details on the extension? Length, pics of the underside, etc?

brian90744

American Trekker

tongue extension

A few pics of extension, mine is 2x3 x58" long side bars , and if you use these longer side bars, the front drain must be eliminated as it right on top of the new side bars. I cut mine out and welded a square plate over the hole. Note: it is easier if you remove the tub. Just FYI= brian

A few pics of extension, mine is 2x3 x58" long side bars , and if you use these longer side bars, the front drain must be eliminated as it right on top of the new side bars. I cut mine out and welded a square plate over the hole. Note: it is easier if you remove the tub. Just FYI= brian

Attachments

Last edited:

Kiddmen57

Supporting Sponsor

A few pics of extension, mine is 2x3 x58" long side bars , and if you use these longer side bars, the front drain must be eliminated as it right on top of the new side bars. I cut mine out and welded a square plate over the hole. Note: it is easier if you remove the tub. Just FYI= brian

Thanks. I'm not sure exactly how I'll be extending mine just yet, was even thinking some sort of pinned hinge that would allow the front to pivot up out of the way (i have very limited space in the garage). That will all happen next summer. Everything will be apart for blasting and powder/ painting.

Kiddmen57

Supporting Sponsor

After a couple uses of the tent I noticed it was getting harder to raise up. It only wanted to slip and not raise. Finally the last time I opened it it got out if sync, so the forward end was fully up but the other end wasn't. I decided to take it apart in order to reset the drive mechanism. Once I got into it I discovered a bit larger problem. The mitre gears that connect the two drive ends were worn. A call to Bobby and new ones are on the way, what a stand up guy!

While investigating further I noticed that the forward gear "bearing" blocks were free to move a bit. This likely exacerbated the slipping problem. So I gathered up materials to add a layer if glass down and stiffen it up. Once I got into it I realized there was more to it than met the eye. The existing glass work was soft and very tacky. I decided to cut the old stuff out. Then I discovered the real issue. Water had gotten into the stud plate and had corroded it and affected the glass in the area.

Fast forward to right now and the old soft yellow glass is out, plate is cleaned and painted. Tomorrow I will set the new plate with non reactive epoxy. After that cures 2-3 new layers of fiberglass will be laid down. I'll install new mitre gears and really work on how well they mesh. This should make the drive mechanism as stout as it can be with the existing design.

While investigating further I noticed that the forward gear "bearing" blocks were free to move a bit. This likely exacerbated the slipping problem. So I gathered up materials to add a layer if glass down and stiffen it up. Once I got into it I realized there was more to it than met the eye. The existing glass work was soft and very tacky. I decided to cut the old stuff out. Then I discovered the real issue. Water had gotten into the stud plate and had corroded it and affected the glass in the area.

Fast forward to right now and the old soft yellow glass is out, plate is cleaned and painted. Tomorrow I will set the new plate with non reactive epoxy. After that cures 2-3 new layers of fiberglass will be laid down. I'll install new mitre gears and really work on how well they mesh. This should make the drive mechanism as stout as it can be with the existing design.

Kiddmen57

Supporting Sponsor

Glued the plate back I today using 3M 8115 panel binding adhesive. This stuff is nearly a miracle material. I didn't need any fiberglass but added a layer to it and will add one more layer overtop with standard poly resin. This will make it nice and smooth. The repair is already stronger than before and more than strong enough to handle the stresses, but I'll make it prettier.

Kiddmen57

Supporting Sponsor

Mostly re-assembled. Picked up a box of washers to shim the new metal bevel gears into tight mesh. Set the timing front to back and side to side. All works smoothly and tight.

Just need to wait for my friend to come over to re-install the top.

Two set screws and red loctite.

Just need to wait for my friend to come over to re-install the top.

Two set screws and red loctite.

charlie harper

New member

Wow great build thread! You have some outstanding skills bro! :Wow1:

I look forward to seeing it all painted!

I look forward to seeing it all painted!

Kiddmen57

Supporting Sponsor

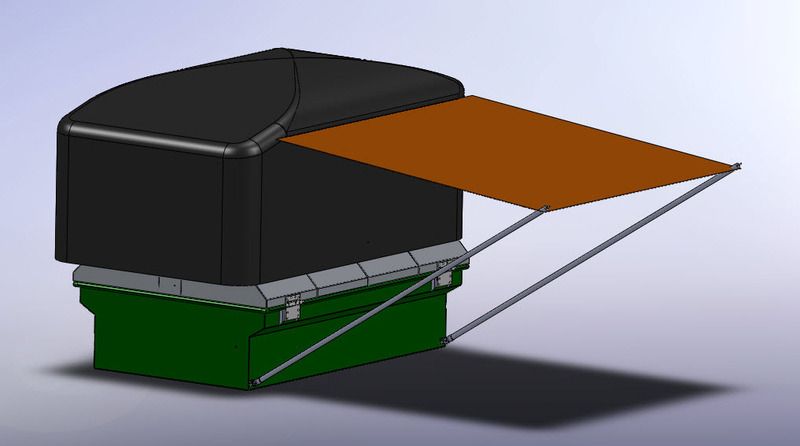

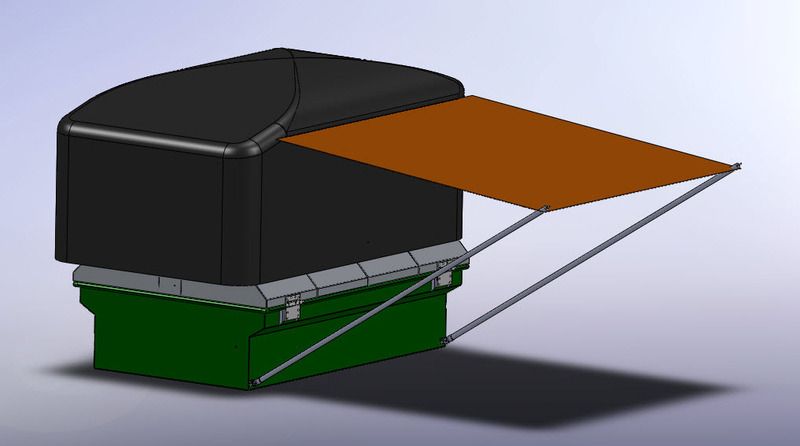

Here is a peek at what the next small project may be. I want to make an ultralight canopy that is supported by the tent/trailer without guy-lines.

I'm thinking of using adjustable tarp poles, fixed and braced to the trailer to be self supporting, with only one edge of the canopy zippered to the tent.

This may take a while to flesh out fully but is something I've been thinking about since i got the tent last year.

I'm thinking of using adjustable tarp poles, fixed and braced to the trailer to be self supporting, with only one edge of the canopy zippered to the tent.

This may take a while to flesh out fully but is something I've been thinking about since i got the tent last year.

brian90744

American Trekker

Trailer awning info

Klayton.

check out http://countryhomescampers.com/products/camper-awning, contact name Salim miro. I think this awning would work great on your trailer. Thank for the atta-boy on my trailer=brian

Klayton.

check out http://countryhomescampers.com/products/camper-awning, contact name Salim miro. I think this awning would work great on your trailer. Thank for the atta-boy on my trailer=brian

Last edited:

Similar threads

- Replies

- 2

- Views

- 820

- Replies

- 2

- Views

- 1K

- Replies

- 32

- Views

- 8K