As I am going through this design, I am also learning a lot. The gas spring thing is a tough component to properly design. The way most of us have them set up means that the springs do not provide a constant force as lift for the lid. I found this website that tells you how to determine the force in each direction from your spring.

http://dev.physicslab.org/Document.aspx?doctype=3&filename=Dynamics_ForcesActingAngle.xml

Basically, My lid at 36 degrees open the way I have the spring mounted will result in an angle of the shock at 57.5*. Taking the sin (57.5*)x200(lbs force on the shock) nets you 168.67 lbs of lift for each spring (200lb spings). This results in 168.7x2= 335.34 lbs of lift. My lid weights 200lbs with the RTT, so I have an extra 135 lbs to overcome to shut the lid.

On the closed side of things, I have a net resultant angle of 18.6 degrees. Using the same calculation sin(18.6)x200 = 63.8 lbs of lift each. 63.8 x 2 = 127.6 lbs of lift. This means I have to lift up ~72.4 lbs to raise the lid. This is why a lot of lids are difficult to open at first, because the angle of the spring when closed pushed all the force laterally, not vertically. If I go to a 175lb spring, then I have less force to overcome pulling the lid closed, but I have even more weight to lift at opening. Also, because of this, at one angle through the opening range of the lid, it will become neutral (force of springs equals the weight of the lid etc).

Ideally the spring would travel equally on either side of vertical through its range. This requires pretty long stroke shocks, which have a compressed length of nearly 20". My trailer tub is not that tall.

Essentially, having the spring as close to vertical as possible is the best for minimizing the variances in lift force.

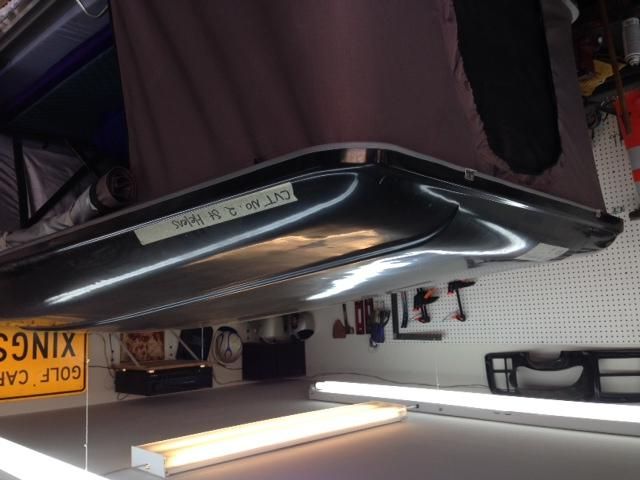

This design was my initial, but I will be changing it to locate the spring more vertical in the closed position.

View attachment 228443

View attachment 228444

View attachment 228445