Get your tickets to THE BIG THING 2026!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New adventure Toy(ota) in AZ

- Thread starter Jrally

- Start date

Jrally

Adventurer

No pictures, but I got the axle reassembled last night. Ran the wire wheel cup on my angle grinder across the top of my knee, then dropped the 3rd member on my lower leg. No pain, no gain! Anyways, now that it's all sealed back up, I can finish cleaning the housing and then shoot a couple coats of satin black on the whole thing before bolting it into the car.

-Jon

-Jon

DR1665

Gearheads United

Wire cup + knee. I had a similar experience with a chainsaw years ago. Got *very* lucky. But yeah, character-building, right?

I take it you've decided to go 1-piece on the prop shaft, then? Does this mean the risk of damage and reduced clearance aren't enough to overcome the benefits from simplicity and (I suspect) cost savings? If you're going to have the driveshaft custom-made, why not ask the professionals what they would recommend? If you'd like a second opinion, there's a thread up in the In-Progress Adventures section with a couple guys up in Canada did a lot of BBQing in BC. They ended up getting a custom axle built on the road and seemed very pleased with the service. Shop name is in the thread. Couldn't hurt to call, right?

EDIT: Here's the page in that thread where they mention the axle shop. Worth a shot.

I take it you've decided to go 1-piece on the prop shaft, then? Does this mean the risk of damage and reduced clearance aren't enough to overcome the benefits from simplicity and (I suspect) cost savings? If you're going to have the driveshaft custom-made, why not ask the professionals what they would recommend? If you'd like a second opinion, there's a thread up in the In-Progress Adventures section with a couple guys up in Canada did a lot of BBQing in BC. They ended up getting a custom axle built on the road and seemed very pleased with the service. Shop name is in the thread. Couldn't hurt to call, right?

EDIT: Here's the page in that thread where they mention the axle shop. Worth a shot.

Last edited:

Jrally

Adventurer

The shop I'm planning on using is very close by my home and office, I already got his opinion. He was the first to suggest going one piece. I was reluctant at first, but after thinking it over for days, talking with a few other people, etc., I've come to the conclusion, try it. If it becomes a problem, then I'll just switch it back to two pieces at that point. The wheel base is short enough and the shaft only sticks down at droop situations. The low point is still the center of the axle, by a long shot.

-Jon

-Jon

Jrally

Adventurer

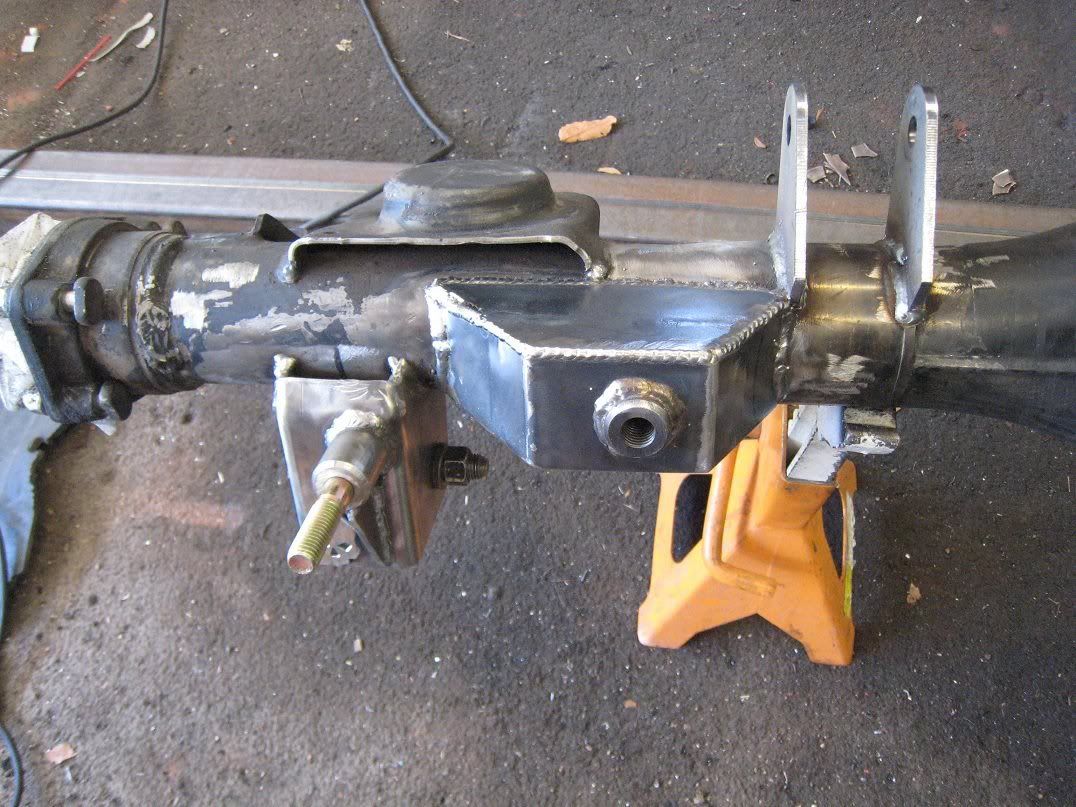

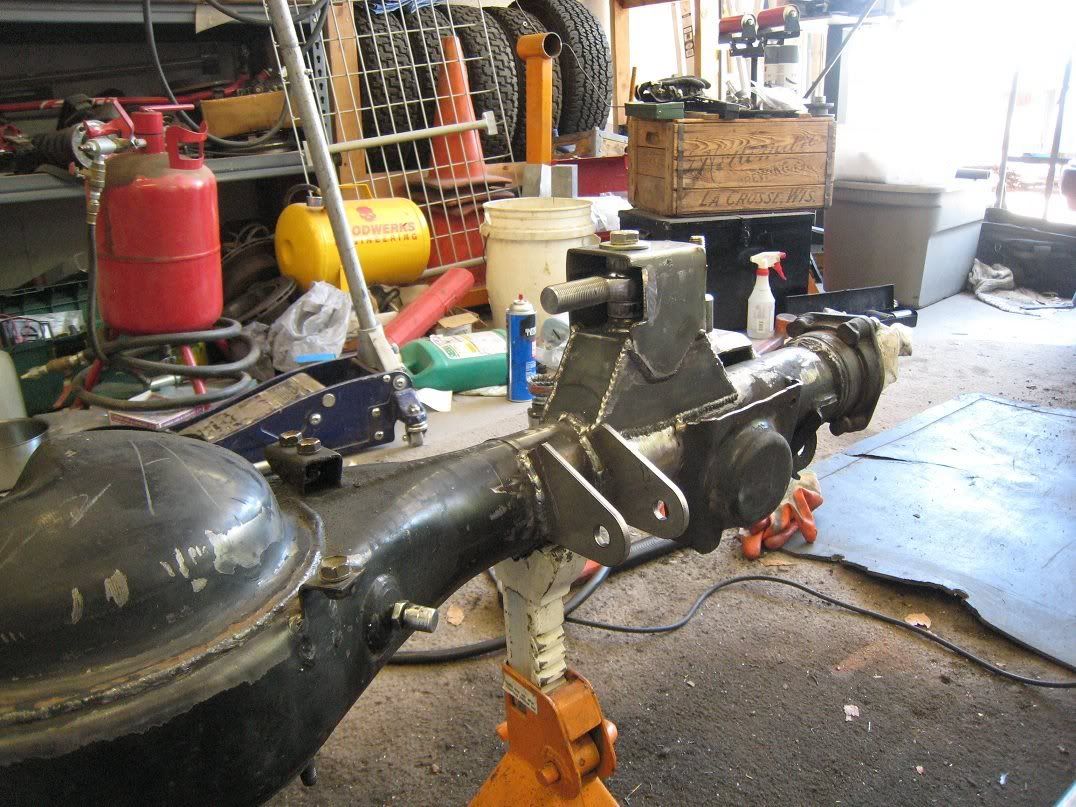

From this -

To this -

in just a few HOT hours of work. I got the car loaded up on the trailer and ready to take to the driveshaft shop. The tricky part this weekend was finding a new flex hose, needed one a bit longer than what I had. After a lot of diggin around on the internet, I found the length numbers I was looking for from RockAutos sight. I ended up buying a 1st gen Tacoma 4x4 rear hose, about 2-2.5" longer than what I had, perfect.

-Jon

To this -

in just a few HOT hours of work. I got the car loaded up on the trailer and ready to take to the driveshaft shop. The tricky part this weekend was finding a new flex hose, needed one a bit longer than what I had. After a lot of diggin around on the internet, I found the length numbers I was looking for from RockAutos sight. I ended up buying a 1st gen Tacoma 4x4 rear hose, about 2-2.5" longer than what I had, perfect.

-Jon

Jrally

Adventurer

And the project of getting an F-code rear axle into Carlos is done... (well, mostly) 20 minutes or less of work got my new TAD 1 piece drive shaft installed. The exhaust is going to need a little moving about, but it's fine for now, doesn't touch at full droop, sitting still, but it's VERY close. The car is completely different, no whinning from the back end, peppy excelleration, etc.. Can't wait to get it in the dirt, see how the LSD really feels.

-Jon

-Jon

Jrally

Adventurer

This weekend, I didn't do a whole lot of work on the car, but I did go buy a salvage yard set of parking brake cables from a van to match the axle. One side fits decently, but the area where the hard clamp mount goes is in a different place on the housing. Not too big a deal, just clamped down where I needed to. The other cable is almost 24" longer than it needs to be, but with some creative routing with smooth curves and a flexible strap to pull it away from the tire seems to make it fit. Last bit is just to get the cables adjusted to actually hold decently.

-Jon

-Jon

Jrally

Adventurer

I'm going to have to get the cables to mount as designed, using the cable end clamps. I've got one side modified for now, the other side is going to reguire some fabrication, but it'll be worth it. I don't like not having a parking brake that works really well. When I'm playing in the dirt, sometimes it's very handy for helping the back end swap over quickly for hair pin turns. Plus, it sucks having to turn the engine off just to stop for a minute.

-Jon

-Jon

De'Angelo Fernandez

New member

Bad ***

Jrally

Adventurer

Adjusted the panhard bar last night, not bad for eye balling it the weekend earlier. I only had to change it by 1/16" to get the axle centered under the body. This morning I dropped the car off for an alignment. It's the one thing that seems to plaque using a car like a truck, the front end needs aligning about every 6 months. But, then again, maybe if I used my Ford Exp. as hard as I use the Celica, then it might need aligning more often too.

Similar threads

- Replies

- 16

- Views

- 376

- Replies

- 0

- Views

- 354