You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New Camper Build - THE OVERL[h]ANDER

- Thread starter msiminoff

- Start date

RAM5500 CAMPERTHING

OG Portal Member #183

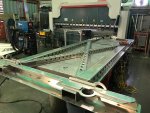

Today's eye candy....

View attachment 587698

This arouses me

msiminoff

Active member

Lots of progress happening this week!

The subframe is complete, rear pivot/winch-mount/hitch is assembled and attached to the truck frame, and the Total Composites floor has been (temporarily) fastened to the subframe for final alignment of the subframe-to-frame mounts & bushings. Lots of measuring and re-measuring going on to make sure that we have proper clearances between the camper box and the cab... So far everything fits exactly as planned.

My hat's off to the crew at Durrance Design for making this look so easy (it isn't!).

The subframe is complete, rear pivot/winch-mount/hitch is assembled and attached to the truck frame, and the Total Composites floor has been (temporarily) fastened to the subframe for final alignment of the subframe-to-frame mounts & bushings. Lots of measuring and re-measuring going on to make sure that we have proper clearances between the camper box and the cab... So far everything fits exactly as planned.

My hat's off to the crew at Durrance Design for making this look so easy (it isn't!).

msiminoff

Active member

Here are a couple more shots of the finished subframe. It is not actually mounted to the truck in these photos, just resting on top of the frame rails. I'll show the details of the pivots and bushings as soon as that assembly complete.

Reuben at DDGO (Durrance Design Group Overland) has done an amazing job with the design, engineering and fabrication of this all-aluminum subframe. I am thrilled with the way the project is coming together so far! Prior to my project, Durrance had been focused primarily on engineering and fabrication for the marine industry; Their projects include elaborate mechanical assemblies, as well as turn-key fabrication of commercial fishing boats. The team's passion for adventure travel has inspired them to expand their service offering to the overloading industry... a wise choice

In addition to building the subframe, Durrance will be assembling the Total Composites camper box for me, as well as fabricating some pretty aluminum accessories (side boxes, rear deck, ladder, bumpers, etc).

Reuben at DDGO (Durrance Design Group Overland) has done an amazing job with the design, engineering and fabrication of this all-aluminum subframe. I am thrilled with the way the project is coming together so far! Prior to my project, Durrance had been focused primarily on engineering and fabrication for the marine industry; Their projects include elaborate mechanical assemblies, as well as turn-key fabrication of commercial fishing boats. The team's passion for adventure travel has inspired them to expand their service offering to the overloading industry... a wise choice

In addition to building the subframe, Durrance will be assembling the Total Composites camper box for me, as well as fabricating some pretty aluminum accessories (side boxes, rear deck, ladder, bumpers, etc).

RAM5500 CAMPERTHING

OG Portal Member #183

Amazing

msiminoff

Active member

No. The subframe was engineered with the knowledge that it would not be heat-treated after assembly, and high-load areas are reinforced accordingly. In addition, the welding strategy is designed to minimize the heat affected zone.Will the sub-frame be heat treated before assembly?

No, the holes won't be plugged. However the subframe is designed to be flushed out with a hose or pressure washer when necessary and there are weep holes to prevent water accumulation.Are you planning on plugging all the holes so that your sub-frame does not fill with dirt, dust, and mud?

Cheers,

-Mark

No. The subframe was engineered with the knowledge that it would not be heat-treated after assembly, and high-load areas are reinforced accordingly. In addition, the welding strategy is designed to minimize the heat affected zone.

No, the holes won't be plugged. However the subframe is designed to be flushed out with a hose or pressure washer when necessary and there are weep holes to prevent water accumulation.

Cheers,

-Mark

DirtWhiskey

Western Dirt Rat

That's some of the most not messing around metal work I've seen on this forum. Kudos to doing it right!

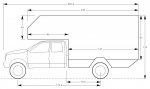

I'm dreaming of a build with similar dimensions, this mockup is super helpful.

Do you have measurements of the planned height/length of your cabover?

Do you have measurements of the planned height/length of your cabover?

Truck and Camper:

View attachment 564716

msiminoff

Active member

Here's another drawing with dimensions (in inches) for the cabover portion.Do you have measurements of the planned height/length of your cabover?

Keep in mind that these are outside dim's... the cabover floor & the ceiling are 3-1/4" (83mm) thick. Walls are 2" (50mm).

Let me know if you need more info.

-Mark

Similar threads

- Replies

- 23

- Views

- 3K

- Replies

- 28

- Views

- 2K

- Replies

- 4

- Views

- 3K

- Replies

- 35

- Views

- 18K