You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New Camper Build - THE OVERL[h]ANDER

- Thread starter msiminoff

- Start date

msiminoff

Active member

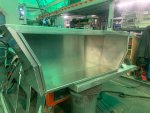

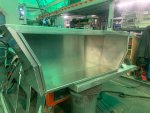

These are the aluminum side-boxes that will be mounted to the camper floor & subframe. There's room to store a metric $hI7-ton of gear in these things.

The boxes will have fold-down doors that can be used as a work surface and all of the latches have been keyed to match the Tern access hatches and Wildlands door.

I can't say enough about the amazing work by the team at Durrance Design Group.

The boxes will have fold-down doors that can be used as a work surface and all of the latches have been keyed to match the Tern access hatches and Wildlands door.

I can't say enough about the amazing work by the team at Durrance Design Group.

Last edited:

RAM5500 CAMPERTHING

OG Portal Member #183

These are the aluminum side-boxes that will be mounted to the camper floor & subframe. There's room to store a metric *******-ton of gear in these things.

The boxes will have fold-down doors that can be used as a work surface and all of the latches have been keyed to match the Tern access hatches and Wildlands door.

I can't say enough about the amazing work by the team at Durrance Design Group.

View attachment 602560

View attachment 602561

View attachment 602562

Looking awesome as usual!

charlieaarons

Explorer

May I suggest thinking about a couple of chassis things:

1) if you haven’t purchased the 19.5s yet, going to 285/70R19.5s or even 305s for at least a hint of better ride on washboard with a bit of deflation and also a bit of flotation on soft ground/sand. There’s gearing considerations with a 10-14% increase in diameter.

2) Especially if you end up doing a ring and pinion swap there’s lockers available for both ends.

An ARB for the front might seem extreme (a rear Detroit or ARB is NOT extreme!) but I can tell you by personal experiences that getting stuck in a heavy vehicle is not fun and worth avoiding with mere mechanical gadgets.

1) if you haven’t purchased the 19.5s yet, going to 285/70R19.5s or even 305s for at least a hint of better ride on washboard with a bit of deflation and also a bit of flotation on soft ground/sand. There’s gearing considerations with a 10-14% increase in diameter.

2) Especially if you end up doing a ring and pinion swap there’s lockers available for both ends.

An ARB for the front might seem extreme (a rear Detroit or ARB is NOT extreme!) but I can tell you by personal experiences that getting stuck in a heavy vehicle is not fun and worth avoiding with mere mechanical gadgets.

msiminoff

Active member

Yes of course, suggestions are always welcomeMay I suggest thinking about a couple of chassis things....

1) I currently have a full set (5) of Vision 19.5's with 245/70 Michelin M729's and a set of (5) 17" Hummer H2 wheels with 295/70 Nitto Terra Grapplers for this truck (see photos above). At this point I am 100% certain that I will not be keeping the H2/Nitto setup because I'll be at or over the load rating for both the wheels and the tires..

I'm going to hold off making any more wheel/tire purchases until I get the weight of the final build... but if the rear axle comes in under 8000lbs (I do expect that I'll be well below that) then I'll pick up a set of 18x9" Method 701HD wheels with some 295/70R18 E 129/126Q NItto Terra Grappler G2's (or maybe Toyo's new Open Country A/T III). That will give me a 34.25" OD, an 8160 lb capacity on the rear axle, plus the ability to safely air-down when off road.

Unfortunately I can't squeeze in the 305-17's or the 285-19.5's under the front fenders unless I add a couple inches of lift and I definitely do not want to do that.

2) Both front and rear axles already have ARB air-lockers in them. I got myself stuck exactly one time in this truck many years ago (I agree, NOT fun at all) and immediately made the decision to add the lockers... I am extremely happy with them! I'll also have from & rear winches on the rig, but if all goes according to plan, they will only be used to recover other people's vehicles

I am currently running 4.11's from Nitro Gear, and I think the gearing is perfect for 33-34" tires.

Cheers!

-Mark

msiminoff

Active member

The side boxes have been installed onto the subframe & camper floor, and the aluminum fender-arches are being fitted into the floor panel.

We'll be powder coating the boxes to match the ("mineral grey") color of the truck body. Construction of the box doors is also underway.

(click thumbnails to see hi-res images)

Here's a fun video of a test of the rear deck and actuator...

And a close-up of the deck in retracted position.

We'll be powder coating the boxes to match the ("mineral grey") color of the truck body. Construction of the box doors is also underway.

(click thumbnails to see hi-res images)

Here's a fun video of a test of the rear deck and actuator...

And a close-up of the deck in retracted position.

Last edited:

msiminoff

Active member

Here are a couple more shots of the finished side boxes with the Tern latches and greasable hinges installed. Next stop is the powder-coating shop and then the bottom surfaces and wheel wells will be sprayed with Rhino Lining to protect them from chips & scratches.

-Mark

-Mark

Alloy

Well-known member

Aluminum is an excellent material but one of its failing is electrolysis. Make sure you have a system to clean 100% (weep holes plug up easily) of the road mud/debris out of the boxed frame or it will be destroyed (even 5086-5083 grades) from the inside out in 4-8 years.... I've seen it happen more than once.No. The subframe was engineered with the knowledge that it would not be heat-treated after assembly, and high-load areas are reinforced accordingly. In addition, the welding strategy is designed to minimize the heat affected zone.

No, the holes won't be plugged. However the subframe is designed to be flushed out with a hose or pressure washer when necessary and there are weep holes to prevent water accumulation.

Cheers,

-Mark

Is the person doing the welding ticketed or certified?

Alloy

Well-known member

X2!!You might want to check out Line-X. I have used both on my vehicles and on equipment I have built for clients and believe Line-X is a FAR superior product.

RAM5500 CAMPERTHING

OG Portal Member #183

You might want to check out Line-X. I have used both on my vehicles and on equipment I have built for clients and believe Line-X is a FAR superior product.

Agree 110%

msiminoff

Active member

Joaquin Suave said:You might want to check out Line-X.

Thanks for the tip! I'll check to see if there's Line-X installer nearby.RAM5500 CAMPERTHING said:Agree 110%

Yes, the crew at DDGO are certified and extraordinarily talented welder/fabricators. Their primary business is the design and manufacture of all-aluminum commercial fishing and transport boats. My truck is by far the least complex project in the shop... but it's being built to the same high standard as their marine industry work.Alloy said:Is the person doing the welding ticketed or certified?

-Mark

msiminoff

Active member

Lots of progress happening this week:

- Subframe is back from powder coating and re-mounted onto the truck.

- The spare tire winch has been re-configured so the hand-crank shaft will now be accessed through the (lockable) rear passenger side-box.

- The truck's rear window has been removed (will be replaced with aluminum plate) and the pass-through opening has been cut in the rear wall of the cab.

Next is the fabrication of the pass-through frame to support the accordion boot.

(Click thumbnail to see hi-res images)

- Subframe is back from powder coating and re-mounted onto the truck.

- The spare tire winch has been re-configured so the hand-crank shaft will now be accessed through the (lockable) rear passenger side-box.

- The truck's rear window has been removed (will be replaced with aluminum plate) and the pass-through opening has been cut in the rear wall of the cab.

Next is the fabrication of the pass-through frame to support the accordion boot.

(Click thumbnail to see hi-res images)

Last edited:

msiminoff

Active member

The pass-through is complete and off to the powder coating shop. This assembly will be the same color as the truck body.

DDGO also fab'd-up a set of aluminum wheel arches to allow plenty of tire clearance, and they even matched the corner radius of the arches to the fiberglass pultrusions to ensure a nice clean appearance once assembled

(Click thumbnails to see hi-res images)

DDGO also fab'd-up a set of aluminum wheel arches to allow plenty of tire clearance, and they even matched the corner radius of the arches to the fiberglass pultrusions to ensure a nice clean appearance once assembled

(Click thumbnails to see hi-res images)

Last edited:

Similar threads

- Replies

- 23

- Views

- 4K

- Replies

- 28

- Views

- 3K

- Replies

- 4

- Views

- 3K

- Replies

- 35

- Views

- 18K