GJStringert

Observer

Thanks! And More Updates!

Well thanks a lot for the kind words everybody! I'll try to answer a few questions here:

@ttravis5446, this bed is a CM "SS" model. They are sold totally plain, no boxes or anything, and can be installed as cheap as $1700 (that's the number I remember when I was calling around last summer). Besides strapping EVERYTHING down, ALL THE TIME, having a flatbed has been such a blessing! The thing's 7 feet wide and indestructible! Also look into Bradford Built beds, I've always liked the look of those.

@Malibusurfer, the entire thing is 1.5x1.5 12ga wall (roughly 1/8th inch wall). The base that rides on the bedrails and the rear standoff are 2.5x2.5 12 ga (just because that matched the width of the bedsides and gave it a nice profile).

@purdytj, thanks! and 12 valves are not awesome. 12 valves are EXTREMELY awesome.

OK, I got to hit the camper for about 10 hours today (I don't have classes on Thursday).

First order of business, get a "subfloor" in. On my flatbed, the bedsides are raised from the bed about 1". This meant that, the way the camper was sitting, all it's weight was riding out on the sides, and not on the "belly" of the bed. So to remedy this, and give myself a bit of "lateral stability", I turned the frame on its side and built the floor down about an inch with some OSB and a TON of sheet metal screws. Eventually I will tar the bottom of this to get it nice and weatherproof, and this is nice because now I have a "skeletal" chassis into which to build my electrical and plumbing. Then, insulation, then another thin sheet of OSB for the "top floor". Hopefully you can see in this picture how the wood dips down into the belly of the bed, below the camper frame:

Also in that picture, you can see where the door will be (still waiting to get that, should probably just get on ebay...), on the rear right corner. Originally I was going to have a rear door, but that turned into trying to "reinvent the wheel", and got a little too complex. I like this approach better because now it's curbside, and won't be a hassle to get into if I'm towing and have the camper on.

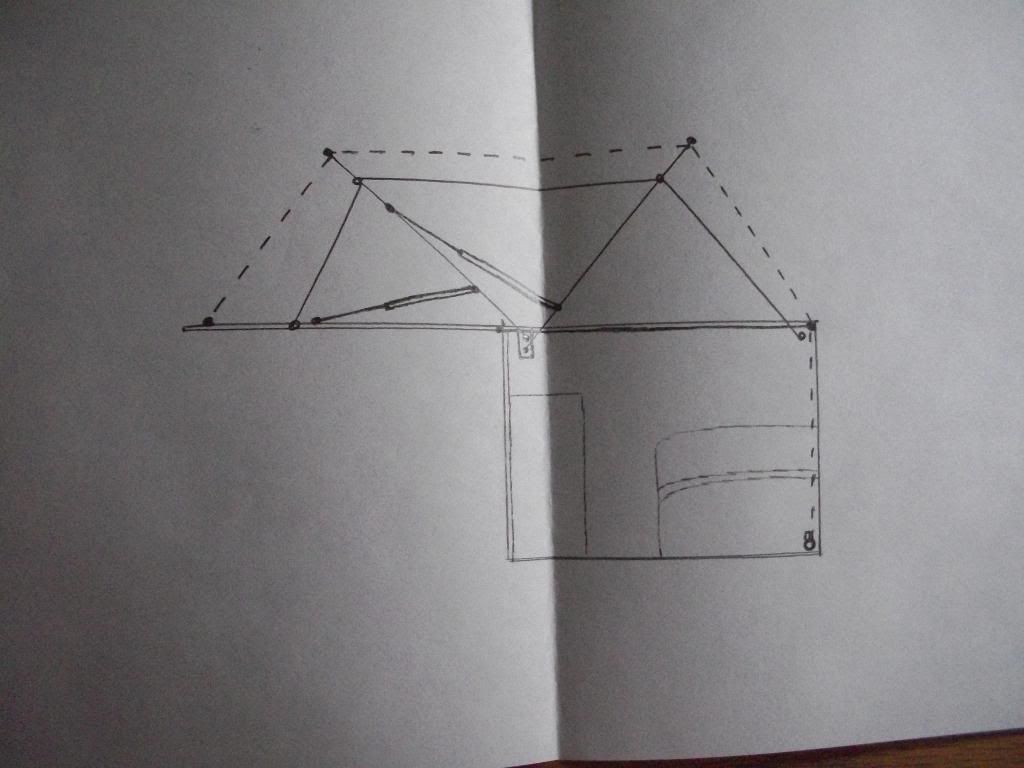

Next up, roof! So, this is hard to understand at the moment, but just think of a flippac, that opens sideways. On the top there is another 1.5x1.5" square that rests perfectly on top of the frame. Nesting inside it is another framework, made of some sch 40 and elbows, that opens and creates a tent frame. This way, my roof now turns into a 7x8 sleeping platform, and when the frame is up (at the height of my scientific 2x4), I'll have around 6'10" of headroom. The only thing I couldn't do today was cut and clamp the cables that will hold the whole ****eree together, just got too tired!

It opens off the passenger side, above the door, so it doubles as a shelter for outdoors as well!

And here's a rough idea of how it all nests back together:

Obviously there's still a ton of work left, but I think this helps give a better idea of the end goal!

Thanks for checking in!

Well thanks a lot for the kind words everybody! I'll try to answer a few questions here:

@ttravis5446, this bed is a CM "SS" model. They are sold totally plain, no boxes or anything, and can be installed as cheap as $1700 (that's the number I remember when I was calling around last summer). Besides strapping EVERYTHING down, ALL THE TIME, having a flatbed has been such a blessing! The thing's 7 feet wide and indestructible! Also look into Bradford Built beds, I've always liked the look of those.

@Malibusurfer, the entire thing is 1.5x1.5 12ga wall (roughly 1/8th inch wall). The base that rides on the bedrails and the rear standoff are 2.5x2.5 12 ga (just because that matched the width of the bedsides and gave it a nice profile).

@purdytj, thanks! and 12 valves are not awesome. 12 valves are EXTREMELY awesome.

OK, I got to hit the camper for about 10 hours today (I don't have classes on Thursday).

First order of business, get a "subfloor" in. On my flatbed, the bedsides are raised from the bed about 1". This meant that, the way the camper was sitting, all it's weight was riding out on the sides, and not on the "belly" of the bed. So to remedy this, and give myself a bit of "lateral stability", I turned the frame on its side and built the floor down about an inch with some OSB and a TON of sheet metal screws. Eventually I will tar the bottom of this to get it nice and weatherproof, and this is nice because now I have a "skeletal" chassis into which to build my electrical and plumbing. Then, insulation, then another thin sheet of OSB for the "top floor". Hopefully you can see in this picture how the wood dips down into the belly of the bed, below the camper frame:

Also in that picture, you can see where the door will be (still waiting to get that, should probably just get on ebay...), on the rear right corner. Originally I was going to have a rear door, but that turned into trying to "reinvent the wheel", and got a little too complex. I like this approach better because now it's curbside, and won't be a hassle to get into if I'm towing and have the camper on.

Next up, roof! So, this is hard to understand at the moment, but just think of a flippac, that opens sideways. On the top there is another 1.5x1.5" square that rests perfectly on top of the frame. Nesting inside it is another framework, made of some sch 40 and elbows, that opens and creates a tent frame. This way, my roof now turns into a 7x8 sleeping platform, and when the frame is up (at the height of my scientific 2x4), I'll have around 6'10" of headroom. The only thing I couldn't do today was cut and clamp the cables that will hold the whole ****eree together, just got too tired!

It opens off the passenger side, above the door, so it doubles as a shelter for outdoors as well!

And here's a rough idea of how it all nests back together:

Obviously there's still a ton of work left, but I think this helps give a better idea of the end goal!

Thanks for checking in!