Here are some updates from the week. Not quite the process that I had hoped for but ended up stuck waiting on some parts to be delivered, and then we had a problem with our welder, but here's where things are...

I pulled out the rear seats and built this storage bench. I'll have most the electrical goodies under there as well as a water tank. We'll make some cushions for the top that will basically make it a huge bed for our pup. The tops will get painted to match. Waiting to have the electrical done before I put the tops on.

Finally got the batteries in and built a quick little box for the. Two 6v 220 amp hour lifelines. The "battery box" eventually got mounted to the bench, and the bench bolted to the floor. They shouldnt be going anywhere. Didnt get much more done on the electrical cause the redarc took forever to get delivered. Got it today tho. Also have the victron battery monitoring system to go with it.

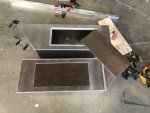

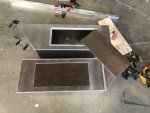

I had my buddy weld these boxes up for me months ago, and I finally got around to cutting them open for the door and cutting the actual doors. I cut the openings with a router and jig I whipped up. First time cutting aluminum with a router, wassnt too bad. I had originally planned on the doors being made from 1/4" richlite and overlapping the opening, with some weatherstripping. basically cause it just seemed like the simplest way to do it. The more I thought about it, I wasnt so keen on that idea, so I had to figure how to inset the doors afterwards. what I ended up doing was taking a piece of 1/4" x 3/4' aluminum flatbar and a piece of 1/8" x 1.5" flatbar and epoxying them together so the 3/4" wide piece sits inside the opening, and the 1.5" wide piece overlaps that and sits inside the box, giving me somewhere to inset the doors and put some weatherstripping. Now the doors will sit flush and hopefully seal pretty well. Also got some sexy boat latches for the doors. Hinges came in the mail today, so hopefully I can get them finished and on the truck soon.

Like I said, we had some problems with our welder yesterday. Not matter how much we opened up the gas, and was acting like it wasnt getting gas. We thought we might have some contaminated gas as this started happening right after we got our tank refilled. We swapped it out, and still had the same problem. My buddy suggested it might be the line has some holes in it so we've got a new one on the way. Bit frustrating, but the sides are together and top sheet of aluminum is tacked up. Welds arent perfect, but its may ladies first alum tig project, so I'm impressed.

I ordered an adjustable trackbar to try and even out this wheel spacing, but I could not for the life of me get the axle to move more than like an 1/8" tried a strap rated at 3000 lbs and it wasnt budging. not sure if I'm missing something, but i'd love to get it more even so I have less wheel rub on the leaf spring. On the plus side, since installing the adjustable track bar, for the first time since putting the rsk and new axle the cab of the truck actually sits straight, so I am pretty stoked on that.

Thats all for now. The rack came back from the powdercoater today, so that is exciting. I can really start putting this thing together now. Heading to Colorado mid july, so gotta get things sorted. Wont be able to do much this weekend, but will have some time early next week, so things should start coming together quick now.