This past weekend I went through and refreshed the rear suspension to regain the 2.5 inches the weight of the camper drops it. Below are some photos.

Removing rubber bushings with 160k on them. Replaced with "prothane" bushings.

Installing add a leaf to the stock spring pack. Would love to sport new custom springs but we're on a tight budget

Then all back together

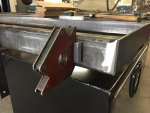

Also finishing up the tail end of the flatbed.

Working on the center panel for the tail lights.......this took 3 tries to get it right. I made it upside down once! By the final one I'd put the jig saw away and started using the plasma cutter.

And then to the bench to weld er' up

And then welded the tail end to the flatbed on the truck

Next, I set the camper on the flatbed to see were the suspension landed. The add a leafs raised it about 2.5 inches and the camper dropped it back down about 2". I also marked the points on the frame where I want to mount the upper airbag supports. All and all it's working out pretty good. Without the airbags it's about 1" higher in the back than in the front and the rear tank is empty(320 lbs.), the camper is not loaded and the flatbed does not have its tool boxes on it yet.

Here's a shot of the back of the camper and the rear of the flatbed. The receiver is not for a trailer hitch, it's for the spare holder apparatus....more weight for the airbags.

Last, I mounted the airbags. I ended up putting the overload springs back on to raise the position of the lower airbag mounting plate.

So next it'll be back to the flatbed to get it 100% finished and the camper mounted to it.