Jmanscotch

is wandering

Took some time today to wrap up the insulation. Still need to tape it in after finishing up the wiring and a few other things.

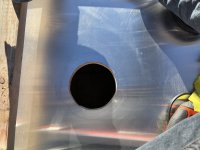

Quick tip: before you put the ceiling insulation in (and the wall insulation if you just have screwed in skins on the side walls) go through and caulk the roof/wall skins to the studs/cross supports. This helps prevent the wind from slapping the thin aluminum skin against the stud during the night while you sleep…a quick and cheap step to help keep the camper more quiet and enjoyable.

Finished the second coat of penetrating epoxy as well. Applied it very liberally and ensured I really soaked the recessed areas and imperfections in the OSB to get full coverage.

That’s it for now, headed off to New York for a little family trip and will finished electrical, install the flooring and begin some interior buildout when we return.

Cheers

Quick tip: before you put the ceiling insulation in (and the wall insulation if you just have screwed in skins on the side walls) go through and caulk the roof/wall skins to the studs/cross supports. This helps prevent the wind from slapping the thin aluminum skin against the stud during the night while you sleep…a quick and cheap step to help keep the camper more quiet and enjoyable.

Finished the second coat of penetrating epoxy as well. Applied it very liberally and ensured I really soaked the recessed areas and imperfections in the OSB to get full coverage.

That’s it for now, headed off to New York for a little family trip and will finished electrical, install the flooring and begin some interior buildout when we return.

Cheers

Last edited: