Alloy

Well-known member

Galley is painted, and electrical/plumbing have been fitted, I will get some photos up tomorrow. I have the main plumbing runs for the drains worked out. Just need to make a bracket to support the drain valve and camlock for the hose.

Planning forward to rebuild the hydronic system, and heating for the underbody lines. I think the easiest method is to isolate from the engine via a plate heat exchanger. I can locate one near the firewall below the brake booster. Then I can run the hydronic system at ambient pressure. A flow through reservoir in the mechanical cabinet (in series with water heater/main loop) should be doable.

View attachment 610315

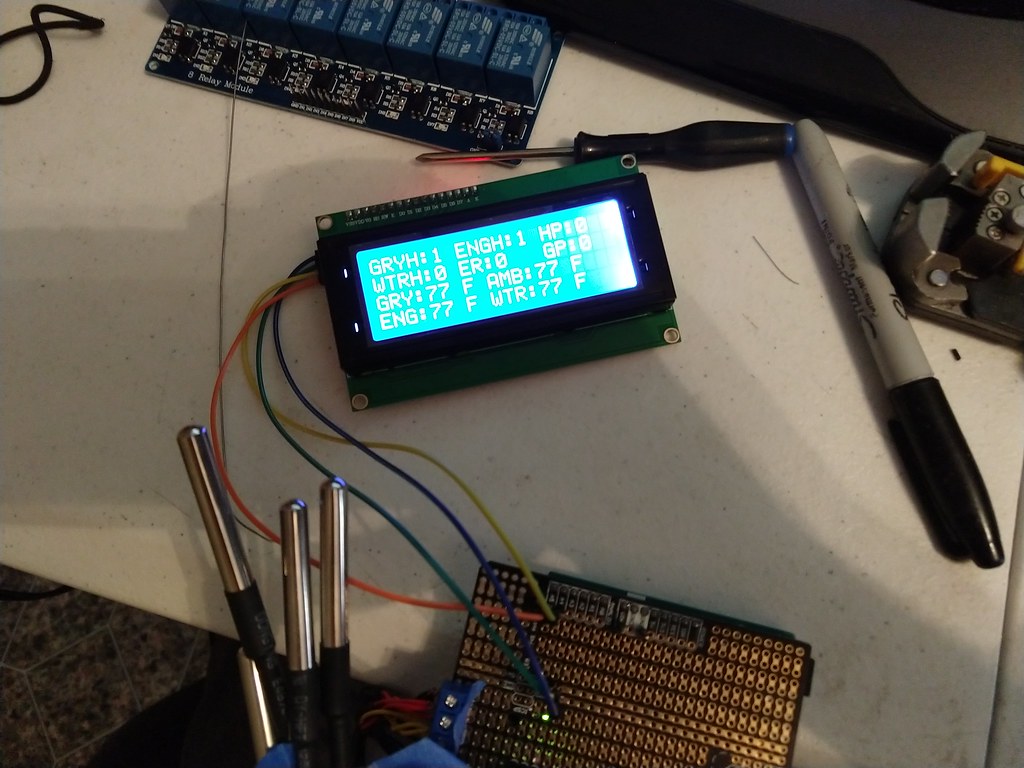

Under the van I can located a manifold pair with shutoff valves. Coolant feeds will be to the Gray tank, drain line feeds, and eventually the fuel tank/lines. I think I can use the grey tank heating loop return to heat the floor under the show pan, and the drain area. Both for comfort and freeze prevention when showering. I am going to need a bunch of different insulation styles, but I think a system without electric valves will be the most reliable. I will waste some heat of course, but with there being a couple gallons of coolant, plus the heat storage in the water heater (its in the main loop), cycle times should be reasonable. The goal is to calibrate the flow to keep the lines/tank above freezing, while the main loop cycles between 120F and 165F. Which lets me use the built in output control (800W or 5kw) of the hydronic heater. So I can just use a digital thermostat with a temp probe on the tanks/lines set for around 40F. Depending on how it works out, I may need a small circulation pump.

Now how the antifreeze lines are plumbed. I am leaning towards them having their own circulation pump, with a hydraulic separator between both (a double ended manifold will work). That way I don't need to shut all the valves when heat isn't needed in that loop. Instead the vales will be for flow control/calibration in each loop.

View attachment 610316

Watch out for dissimilar metals especially if the sytem is open (non pressurized) system that will allow the introduction of oxygen. Aluminum is a great material but hydronci isn't the best place for it.

You'll want to use some of this on any system.

A manifold made for hydronic heating will have balancing valves and flow meters. If there is no flow meters balancing can be done with a point and shoot thermostat.

IMG_20200902_162427165

IMG_20200902_162427165